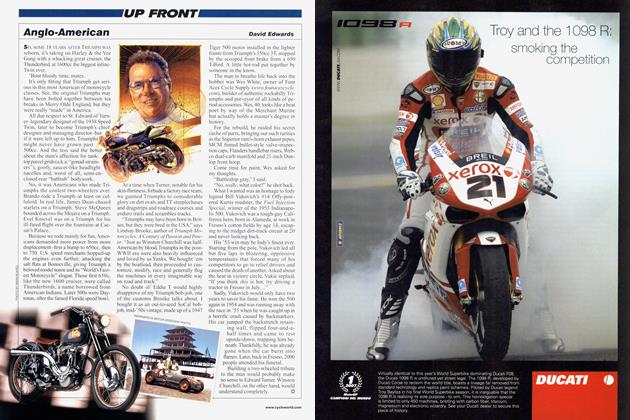

Candid Cameron

Q Regarding the Moto Czysz ("American Racer: MotoCzysz C1," April, 2008), Nick lenatsch used a new-to-me term, "floating, recirculating bearings," as opposed to "linear fork bearings." It seemed to come out of the blue and left me scratching my head and wondering what the heck he meant—even whether he was referring to front-suspension forks or shifting forks. Fid Hawser

Long Beach, California

A My parents’ 1951 Kaiser automobile had a bumper jack with a recirculating ball screw. What this meant was that the long screw which the motorist turned to lift the car had a screw-like thread on it, but with grooves that were semi-circular in section rather than the V-shape of normal threads. Sliding over this was a long nut, similarly threaded on its inside, also with its grooves in semi-circular section. These “threads" did not engage each other. Rather, a great many tiny steel balls were fed into the thread, with half of each ball engaging the screw and the other half engaging the nut. Because of this rolling contact, it was quite easy for 10-year-old me to turn the screw and lift the car.

Ah, but what happens when the rolling balls come to the end of the nut and fall out on the ground? This was prevented by providing a roughly S-shaped steel tube that collected the balls as they emerged from the nut, then conducted them to the other end of the nut where they were fed back into the “thread."

Now imagine making a straight-line, or linear, version of this same concept. As before, motion of the slider releases balls at its trailing edge and needs new ones to support its leading edge-same as moving something heavy on rollers. As with the recirculating ball screw described above, there is a tube that collects the emerging balls and carries them back to the leading edge. Lots of machine tools use such linear ball bearings.

Now think of a conventional motorcycle front fork. When you brake hard on a bumpy surface, the braking force causes heavy loading between the bushings and fork tube, resulting in friction that makes the fork hard to move. As a result, the fork cannot accurately “track" the bumpy road surface, but skips and hops some of the time, reducing tire grip. It would be nice to replace the sliding bushings with recirculating ball linear bearings because their rolling friction would be attractively less than the sliding friction of bushings. This is just what has been done in the Czysz fork and in at least one other, designed by Nikko Bakker in Holland. -Kevin Cameron

View Full Issue

View Full Issue