SERVICE

Slammed or damned?

PAUL DEAN

Q This past spring, I purchased a new Suzuki SV650 after a hiatus of 25 years. I like the bike except for a couple of things: The throttle-or should I say on/off switch-reminds me of the first-year Suzuki TM400 (nope, this ain't my first dance), and the seat is a little high on occasion for a person with rheumatoid arthritis. My question is, if I get a lowering link for the rear suspension and just slip the fork tubes up in the triple-trees, what can I expect other than reduced clearance? Paul Wellendort Burleson, Texas

A What you get depends upon how the modification is done and to what extent. Lowered bikes are easier for a rider to mount, obviously, and they usually handle and steer more lightly by virtue of having a lower center of gravity. But they lose both vertical ground clearance (important if you ever have to ride off a curb or over a tall

speed bump) and cornering clearance (limiting the bike's maximum attainable lean angle). The sidestand also has to be shortened so the bike will lean over on it securely when parked. There are other considerations, as well. Linkage-type single-shock rear suspensions are progressive in that the spring and damping rates, as measured at the rear wheel, increase as the suspension compresses. A lowering link alters that progression and changes the wheel rates at any given point in the travel. In most cases, this results in a slightly harsher rear ride. In the front, sliding the tubes up through the triple-clamps doesn't change the fork's ride qualities, but you usually cannot lower the front as much as the rear. Most lowering links intended for all-around Street riding (rather than drag racing) drop the rear up to I `/2 inches, but it's too risky on most sportbikes to exceed a ¾-inch drop up front. Other wise, the fender could hit the underside of the bottom triple-clamp under full

compression; and if the fender is plastic, it can deform enough to get forced down onto the front tire and lock the wheel. If, however, the front is not lowered an amount equivalent to that of the rear, the steering geometry will be altered. Both the rake and trail will increase, which usually makes the bike marginally more stable in a straight line but slightly slower in its turning response. This is why it is advisable to have such work performed by suspension special ists, particularly if it involves a drop of more than an inch. Specialists have the ability and the tools necessary to modify the suspension in ways that limit the performance compromises that can result when a bike is lowered.

The rev ceiling

Q I really appreciated the question about engine design ("Engine eering") by Andy Hoover and your answer in the February issue. Could you elaborate a little farther in the area of

redline determination? I assume that material strength and engine type/ design play a factor but would like to have a better understanding as to how the value is calculated. Since I'm an owner of a 2006 Yamaha R6, this is an issue of particular interest to me. Randy Brown Posted on www. cycleworid. corn

A The answer to that question

depends upon the answers to a whole battery of other questions-such as, what is the engine’s displacement? How many cylinders does it involve? What are the bore and stroke dimensions? How often will the engine reach redline? And for how long? Will it power a typical road machine expected to last many tens of thousands of miles or a competition-only vehicle that has its engine rebuilt every few races? Those factors and several more weigh heavily in an engine designer’s or builder’s determination of the redline.

In the end, the objective is to prevent certain engine parts from either tearing themselves apart due to inertial forces resulting from their incredible rates of acceleration and deceleration (usually discussed in terms of “piston speed”), or from being destroyed through unintended contact with other engine parts (“valve float” is the most common instance).

Designers of street engines like to keep piston speed below about 4500 feet per minute; if it gets very far above that, piston/connecting-rod life is disproportionately shortened. On the other hand, some racing engines reach piston speeds close to 6000 fpm (the equivalent of a football field every three seconds), but they usually do it only in very brief spurts and require frequent rebuilds-if they don't grenade themselves first. Not only does piston stroke help determine maximum piston speed (and, therefore, maximum rpm), but so does piston weight; obviously, the inertial forces of a 2-inch piston moving at 4500 fpm are much less than with a 4-inch piston at the same speed. But regardless of piston size, the designers try to keep piston weight as low as is reasonably possible.

Then there’s valve float to deal with.

A valve spring can only keep the valve and its attendant follower in contact with the cam lobe up to a certain engine speed; at some point, the valve’s inertia causes it to continue opening on its own, separating from the profile of the cam

lobe before spring pressure can force it closed. Valve float can easily lead to the valve getting bent or broken through contact with the piston crown. These inertial matters are why engineers use ultra-light valve materials when designing high-rpm engines, and why putting four smaller valves in a cylinder of a given size usually results in a higher redline than using two larger valves. Even with positive-closing valve gear such as the desmodromic system used by Ducati, excessively high rpm can either quickly damage the valve and its seat (best case) due to the pounding caused by too-fast closing rates, or it can just snap the head off the valve altogether (worst case). There are numerous other factors that govern maximum engine rpm, but these are the two primary ones.

By the way, your R6, which has a 42.5mm (1.67 inch) stroke, redlines at an actual 15,900 rpm (not 17,500 as indicated on the tach). That works out to a piston speed of 4434 feet per minute. Not to worry, in other words.

Fouled FizzyOne

Ql’ve got a 2004 Yamaha FZ1 with 5000 miles on the odometer. It’s been an awesome-running bike until just recently when it fouled the plugs as I used full choke for the initial start on a warm day. That was the first time it ever did that. Usually, the revs would climb up right after starting and then drop after a second or two, then gradually climb back up to 2500 or 3000 rpm. When the plugs failed, they were wet and black. I changed them, which seemed to help for a bit, but they started fouling again, and the last time 1 tried to start the engine, it backfired loudly. Any ideas? Jim Grigsby

Posted on www.cycleworld.com

Aí think I know the cause of your FZ 1 ’s problems, but before addressing that matter, there’s a couple of terminology issues we need to straighten out. First, you said you used “full choke” when trying to start the engine, but that’s incorrect; your FZ1 does not have a choke. Like many other carbureted motorcycles, it instead uses a cold-start enrichener system involving separate fuel-metering circuits in each carburetor.

When you turn on the enricheners, you open a plunger valve in each carb that allows engine vacuum to draw a very rich fuel mixture into that carb’s bore, just on the engine side of its butterfly valve. It has much the same effect as a choke but achieves it in a different way.

Second, if you are referring to an explosive bang out the exhaust when you say “backfiring,” that is actually called “afterfiring.” It is so named because it occurs in the exhaust, after any unburned mixture has left the combustion

chamber. Similarly, “backfiring” is when the engine spits back through the intake before the mixture exits the combustion chamber.

It is my belief that your FZl’s enrichener valves are not fully closing and in fact have not closed since the

aforementioned incident back when the problem first arose. Trying to start the engine on that warm day with “full choke” produced a fuel mixture too rich for the conditions, fouling the sparkplugs. Installing fresh plugs allowed the engine to start, but the problem quickly resurfaced because the enrichener valves remained open, continuing to deliver a too-rich mixture that eventually fouled the plugs again. Afterfiring also is a symptom of an excessively rich mixture. Unburned fuel accumulates in the exhaust and is ignited when met by the next wave of hot gases.

Since all four of your FZ 1 ’s plugs are fouling, something in the enrichener system is preventing all four plunger valves from closing. To find out what the culprit might be, you need to remove the gas tank and, with the engine off, keep opening and closing the enricheners while closely watching every part of their operating system, from the cable on the handlebar to the linkage that connects all four plunger valves. Using that method, the cause of the hang-up should be easy to find and repair.

Whine connoisseur

QIn the January test of the 2007 Harley-Davidson Fat Boy, you wrote a short accompanying article (“Hot Wheels?”) describing owner complaints about engine-heat problems with the new 96-inch motor. That was informative, but I found it odd that neither the test nor your article mentioned another complaint registered by many owners of ’07 Twin Cam Harleys: a noisy fifth gear in the new six-speed transmission. The bikes run very quietly in all the other gears but produce a lot of whine and rumble in fifth. I’ve heard this noise myself when riding two of my friends' new Electra Glides-one an Ultra Classic and the other a Standard-and that’s why I’m still hanging onto my 2003 Road Glide instead of trading up to an '07. Are you aware of this problem, and if so, do you know how Harley is handling it? Brian Kilpatrick

San Angelo, Texas

A Yes, I am aware of the fifth-gear noise; and as far as I can determine. Motor Company officials are not “handling” it, because they do not see it as a problem. Though no company representatives agreed to be quoted, they

did claim that fifth gear in the sixspeed transmission is no louder than some of the other gears in the previous five-speed box, and that the number of complaints they have received on this matter is comparatively small. They also said those complaints were almost exclusively from owners of ’07 models with fairings, which tend to reflect driveline noises up into the cockpit, and that in their opinion, those riders only noticed the noise because all the other gears in the six-speed box were so quiet.

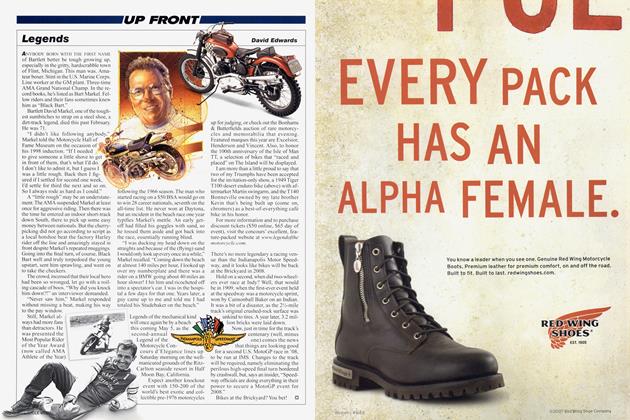

As you may be aware, H-D’s sixspeed Cruise Drive transmission uses helical gears everywhere but on first and fifth, which still are of the straight-cut variety; sixth gear is direct, involving no gear reductions within the transmission. (Fifth gear is the purple gearset in the accompanying illustration.) The use of helical gears, which are quieter than straightcuts, is intended to help the new Twin Cam models comply with evertightening sound regulations all around the world. In some countries, sound tests must be conducted in second gear, while others mandate

third or fourth; that is the main reason those three gears are helical.

A drawback of helical gears is that they are constantly thrust to one

side or the other as the result of the angularity of their teeth. So in many transmissionsincluding this one-

straight-cuts are used on first gear to eliminate the huge side thrust produced by the sizable torque multiplication in that gear. When I asked Harley representatives why fifth was not also a helical set, the only answer I could get was, “It was a decision that took several factors into consideration,” but no one would acknowledge what those factors were.

For right now, the sole option for riders who consider this noise unbearable comes from the aftermarket. Baker

Drivetrain

(877/640-2004; vvrnv. bakerdrivetrain.com), the

Michigan company specializing in H-Dstyle transmissions, is now offering what it calls F6F, a kit that includes a replacement fifth-gear set cut with helical teeth. The kit also comes with a beefier bearing-retainer plate (“trapdoor” in H-D lingo), wider bearings and upgraded mounting hardware. This fix won’t come cheaply, though: The kit itself is $899, and installation entails 4lA to 5 hours of labor. I guess that will serve as a test of just how much any ’07 Twin Cam rider hates the fifth-gear noise. □

Recall Roster

NHTSA Recall No. 06V474000 Harley-Davidson FXDWG/FXDWGI Dyna Wide Glide

Model years: 2006-07 Number of units involved: 10.397 Problem: The internally wired handlebars have a potential to crack at the hole where the wires exit the bars between the handlebar clamps. Should these cracks progress to the point of breaking the handlebar into two pieces, a loss of control could result, increasing the risk of a crash that could cause injury or death to the rider.

Remedy: Dealers will replace the handlebar with one that has both a greater wall thickness and a wire-exit hole with a shape that reduces stress concentration.

NHTSA Recall No. 06V476000 Harley-Davidson XL1200 and XL883 Sportsters Model year: 2007 Number of units involved: 18,758 Problem: As a result of greater body thickness than in previous model years, the voltage regulator may contact the front fender under certain conditions.

In some cases, this may allow the front fender to catch on the top side of the regulator body, which could impede the operator’s ability to steer the vehicle. This could result in a crash that could cause injury or death to the rider. Remedy: Dealers will install an intermediate mounting bracket that relocates the voltage regulator to a position that provides more clearance from the fender. Owners not receiving either of these free remedies should contact Harley-Davidson at 414/3434056.

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/6310651; 3) e-mail it to CW1Dean@aol.com; or 4) log onto www.cycleworld.com, click on the “Contact Us” button, select “CW Service” and enter your question. Don’t write a 10page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.