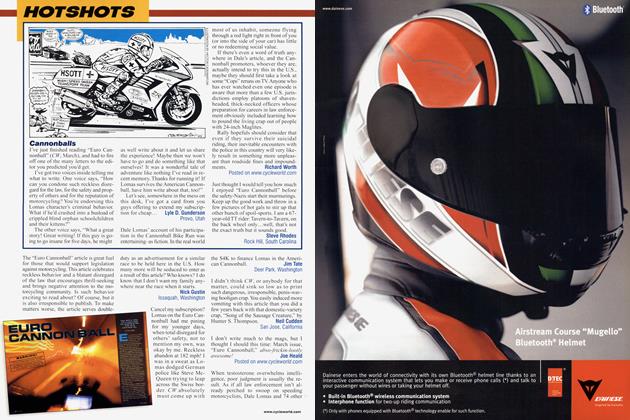

DIESEL POWER!

ROUNDUP

THE DIESEL ENGINE HAS come a long way from the ones offered in rattling, smoke-belching slow cars of the Seventies and Eighties. Today, more than half the cars sold in Europe are very efficient and highly powerful turbo diesels, so it makes sense that an attempt to manufacture a two-wheel version should also come from the Continent.

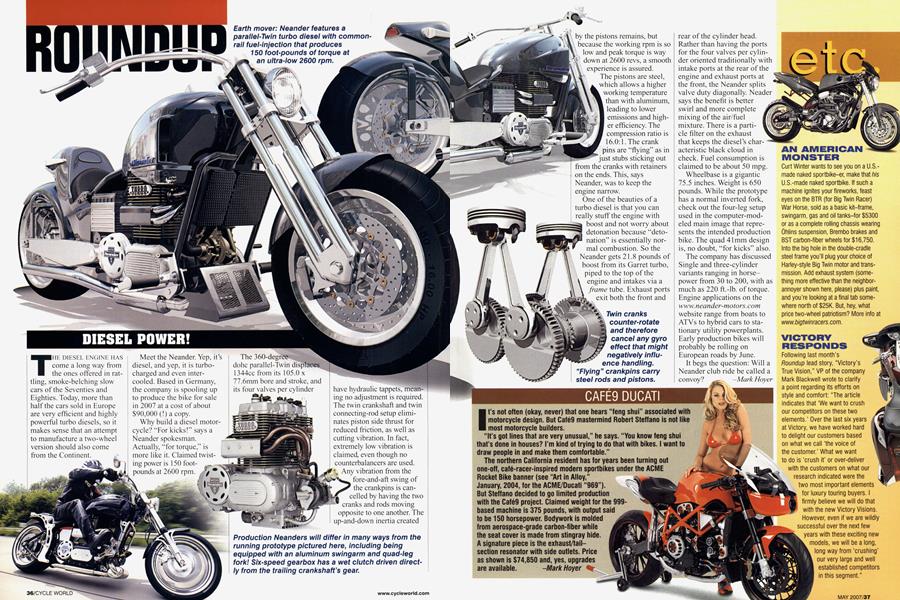

Meet the Neander. Yep, it's diesel, and yep, it is turbocharged and even intercooled. Based in Germany, the company is spooling up to produce the bike for sale in 2007 at a cost of about S90,000 (!) a copy. Why build a diesel motor cycle? "For kicks!" says a Neander spokesman. Actually, "for torque," is more like it. Claimed twisting power is 150 foot poundsat 2600 rpm. `

The 360-degr dohc parallel-Twin disp aces 1344cc from its 105.0 x 77.6mm bore and stroke, and its four valves per cylinder

have hydraulic tappets, mean ing no adjustment is required. The twin crankshaft and twin connecting-rod setup elimi nates piston side thrust for reduced friction, as well as cutting vibration. In fact, extremely low vibration is claimed, even though no counterbalancers are used. W Any vibration from the ` fore-and-aft swing of the crankpins is can celled by having the two cranks and rods moving opposite to one another. The up-and-down inertia created

by the pistons remains, but because the working rpm is so low and peak torque is way down at 2600 revs, a smooth experience is assured.

The pistons are steel, which allows a higher working temperature than with aluminum, leading to lower emissions and higher efficiency. The compression ratio is 16.0:1. The crank pins are “flying” as in just stubs sticking out from the cranks with retainers on the ends. This, says Neander, was to keep the engine narrow.

One of the beauties of a turbo diesel is that you can really stuff the engine with boost and not worry about detonation because “detonation” is essentially normal combustion. So the Neander gets 21.8 pounds of boost from its Garret turbo, piped to the top of the V engine and intakes via a \ frame tube. Exhaust ports rjL exit both the front and

rear of the cylinder head. Rather than having the ports for the four valves per cylinder oriented traditionally with intake ports at the rear of the engine and exhaust ports at the front, the Neander splits valve duty diagonally. Neader says the benefit is better swirl and more complete mixing of the air/fuel mixture. There is a particle filter on the exhaust that keeps the diesel’s characteristic black cloud in check. Fuel consumption is claimed to be about 50 mpg.

Wheelbase is a gigantic 75.5 inches. Weight is 650 pounds. While the prototype has a normal inverted fork, check out the four-leg setup used in the computer-modeled main image that represents the intended production bike. The quad 41mm design is, no doubt, “for kicks” also.

The company has discussed Single and three-cylinder variants ranging in horsepower from 30 to 200, with as much as 220 ft.-lb. of torque. Engine applications on the www. neander-motors. com website range from boats to AT Vs to hybrid cars to stationary utility powerplants. Early production bikes will probably be rolling on European roads by June.

It begs the question: Will a Neander club ride be called a convoy? ^ -Mark Hoyer