SERVICE

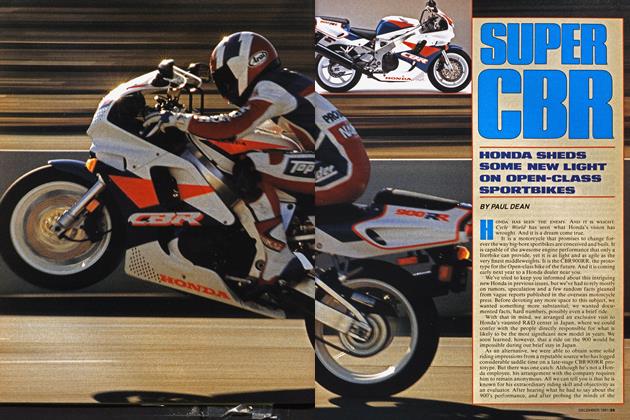

PAUL DEAN

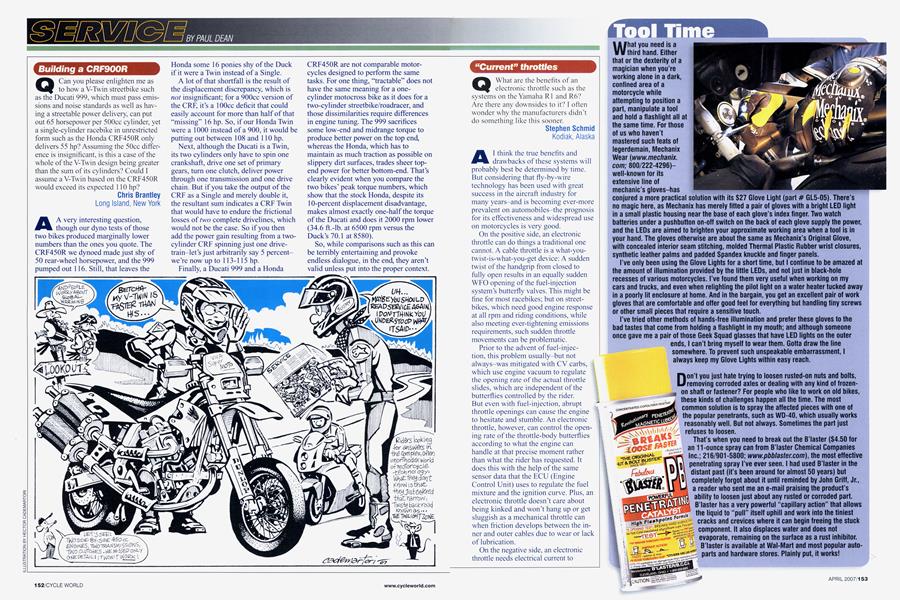

Building a CRF900R

Q Can you please enlighten me as to how a V-Twin streetbike such as the Ducati 999, which must pass emissions and noise standards as well as having a streetable power delivery, can put out 65 horsepower per 500cc cylinder, yet a single-cylinder racebike in unrestricted form such as the Honda CRF450R only delivers 55 hp? Assuming the 50cc difference is insignificant, is this a case of the whole of the V-Twin design being greater than the sum of its cylinders? Could I assume a V-Twin based on the CRF450R would exceed its expected 110 hp? Chris Brantley Long Island, New York

A very interesting question, though our dyno tests of those two bikes produced marginally lower numbers than the ones you quote. The CRF450R we dynoed made just shy of 50 rear-wheel horsepower, and the 999 pumped out 116. Still, that leaves the

Honda some 16 ponies shy of the Duck if it were a Twin instead of a Single.

A lot of that shortfall is the result of the displacement discrepancy, which is not insignificant; for a 900cc version of the CRF, it’s a lOOcc deficit that could easily account for more than half of that “missing” 16 hp. So, if our Honda Twin were a 1000 instead of a 900, it would be putting out between 108 and 110 hp.

Next, although the Ducati is a Twin, its two cylinders only have to spin one crankshaft, drive one set of primary gears, turn one clutch, deliver power through one transmission and one drive chain. But if you take the output of the CRF as a Single and merely double it, the resultant sum indicates a CRF Twin that would have to endure the frictional losses of two complete drivelines, which would not be the case. So if you then add the power gain resulting from a twocylinder CRF spinning just one drivetrain-let’s just arbitrarily say 5 percentwe’re now up to 113-115 hp.

Finally, a Ducati 999 and a Honda

CRF450R are not comparable motorcycles designed to perform the same tasks. For one thing, “tractable” does not have the same meaning for a onecylinder motocross bike as it does for a two-cylinder streetbike/roadracer, and those dissimilarities require differences in engine tuning. The 999 sacrifices some low-end and midrange torque to produce better power on the top end, whereas the Honda, which has to maintain as much traction as possible on slippery dirt surfaces, trades sheer topend power for better bottom-end. That’s clearly evident when you compare the two bikes’ peak torque numbers, which show that the stock Honda, despite its 10-percent displacement disadvantage, makes almost exactly one-half the torque of the Ducati and does it 2000 rpm lower (34.6 ft.-lb. at 6500 rpm versus the Duck’s 70.1 at 8580).

So, while comparisons such as this can be terribly entertaining and provoke endless dialogue, in the end, they aren’t valid unless put into the proper context.

"Current" throttles

Q What are the benefits of an electronic throttle such as the systems on the Yamaha RI and R6? Are there any downsides to it? I often wonder why the manufacturers didn’t do something like this sooner.

Stephen Schmid

Kodiak, Alaska

Aí think the true benefits and drawbacks of these systems will probably best be determined by time. But considering that fly-by-wire technology has been used with great success in the aircraft industry for many years-and is becoming ever-more prevalent on automobiles-the prognosis for its effectiveness and widespread use on motorcycles is very good.

On the positive side, an electronic throttle can do things a traditional one cannot. A cable throttle is a what-youtwist-is-what-you-get device: A sudden twist of the handgrip from closed to fully open results in an equally sudden WFO opening of the fuel-injection system’s butterfly valves. This might be fine for most racebikes; but on streetbikes, which need good engine response at all rpm and riding conditions, while also meeting ever-tightening emissions requirements, such sudden throttle movements can be problematic.

Prior to the advent of fuel-injection, this problem usually-but not always-was mitigated with CV carbs, which use engine vacuum to regulate the opening rate of the actual throttle slides, which are independent of the butterflies controlled by the rider.

But even with fuel-injection, abrupt throttle openings can cause the engine to hesitate and stumble. An electronic throttle, however, can control the opening rate of the throttle-body butterflies according to what the engine can handle at that precise moment rather than what the rider has requested. It does this with the help of the same sensor data that the ECU (Engine Control Unit) uses to regulate the fuel mixture and the ignition curve. Plus, an electronic throttle doesn’t care about being kinked and won’t hang up or get sluggish as a mechanical throttle can when friction develops between the inner and outer cables due to wear or lack of lubrication.

On the negative side, an electronic throttle needs electrical current to

function, so a lack of same means the butterflies are inoperative. What’s more, when electronic components fail-a+s they sometimes do-diagnosing the problem easily can be more complicated and expensive. Figuring out what’s wrong with a mechanical cable doesn’t require a black belt in diagnostics; you pull on one end and see what happens at the other. Not so simple with an electronic throttle, since much of its operation is not visible to the naked eye. Nevertheless, look for electronic throttles soon to become the rule rather than the exception on motorcycles.

Out with the new

QI am intrigued and a little bothered by the engine designs currently in use on four-cylinder sport motorcycles. Over the past 10 or 15 years, the cylinders on these engines have gradually been tilted farther and farther forward from their traditional upright position, which has forced the intake manifolds to become closer to vertical. This has required the airboxes to occupy much of the area formerly devoted to the gas tank, so the tanks now must be exceptionally wide and bulky to maintain sufficient capacity. It seems to me that the old way, with vertical cylinders, was more reasonable. The carburetors or fuel-injection throttle bodies were housed behind the cylinders where they were easy to reach, the air-filter element was usually accessible under the seat or through a side trapdoor, and the entire gas tank could be used for gas and nothing else. Why have these current designs become so impractical?

Carson Richtmeyer Baltimore, Maryland

A The engines in question have evolved in such a manner because of a single fact of aerodynamics: Air absolutely hates to turn corners. When it has to do so in an intake tract, turbulence is created on the trailing side of the sharpest radius (the inside) of the corner, impeding the smooth flow of air and disrupting consistent atomization of fuel. As a result, engine designers for years have tried to keep the intake tract as straight as seemed reasonable for the task at hand.

Up until sometime in the 1980s, cylinder heads used comparatively wide valve angles (the number of degrees between the centerline of the cylinders and the angle of the valve stems), sometimes as much as 30 or 40 degrees. That yielded domed, hemisphericalshaped combustion chambers-believed to be the hot ticket at the time-and intake tracts that could be fairly straight between carburetors and intake valves if the carbs were located more or less directly behind the cylinders.

As the performance wars heated up and sporting motorcycles began evolving into unimaginably powerful racer-replicas, the engineers gradually determined that narrower valve angles and flatter combustion chambers could draw mixture in more effectively, atomize it more finely, burn it more completely and force it out more quickly, all factors that contribute to the production of more power, especially at ultra-high rpm. Consequently, valve angles have become so shallow (some as little as 12 degrees) that intakes and

exhausts on some current engines are almost parallel to one another.

Problem is, the more upright the valve angle with the intake tract in the “traditional” location, the sharper the corner the mixture must turn for it to pass the head of the valve and enter the combustion chamber. The logical solution was to tilt the intake tract upward to where it would have essentially a straight shot at the backside of the valve.

Problem solved? Not quite. At about the same time, engineers were also faced with the challenge of making sportbike chassis as agile and responsive as they could manage. That involved, among numerous other design goals, lowering the bike’s overall center of gravity and locating as much of its mass as possible as close as possible to that center of gravity-mass centralization, it was called. One way to help accomplish such an objective was to tilt the cylinders forward, which not only lowered the eg but also put more weight on the front wheel to aid the bike’s cornering ability at racetrack speeds.

So far, so good. But where to put the airbox now that the intake tract is practically pointing straight upward? Again, logic prevailed and the airbox was incorporated into the front portion of the gas tank, just above the intake stacks. This forced sportbike gas tanks to be rather fat and humpbacked to compensate for the volume consumed by the airbox, but even that isn’t really much of a compromise; width-wise, the tanks generally conform to the shape of the typical sportbike perimeter frame that connects the swingarm pivot and steering head most directly by wrapping around the cylinder heads.

It's the pits

QI know several Kawasaki

ZZR 1200 owners who have the same problem: Their bikes’ cam lobes become pitted after about 15,000 miles. Some of those owners who bought the extended warranty have had the cams replaced by the dealer with no charge, while others have just continued to ride their bikes and leave the pitted cams alone. I also own a ZZR 1200, a 2004 model, and when I did my 7500-mile maintenance, which included a valve adjustment, a few of the cam lobes were starting to show signs of wear with some scratches and scoring. I have to assume that somewhere around the 15,000-mile mark, I will find some pitting on the cam lobes. Replacing the cams is an expensive repair, and there is no guarantee that the problem will not return. I would like to know if I am faced with any possible performance or long-term reliability problems if I continue to ride the bike with the pitted cam lobes. John L. Smith

Phoenix, Arizona

Al doubt I can answer that

question to your full satisfaction, John, because the lifespan of pitted cam lobes is dependent on the nature of the pitting. I’ve seen lobes and followers that looked to be fairly heavily pitted yet lasted for more than 30,000 or 35,000 miles before needing to be replaced, while others with what seemed like much less severe pitting were junk in less than 5000 miles. If the pits are more like tiny craters that are flush with the surface of the lobes rather than little volcanoes that poke upward, the cams could run for a long time without problem. When the pits are either flush with or below the surface, no part of the lobe or its mating follower is being scuffed away every time it wipes across the follower. But if the pits are of the

“volcano” variety, the wear rate will be exceptionally fast, causing the lobe to quickly deteriorate.

You could make a strong case for continuing to ride your ZZR until the question answers itself. Although some ZZR engines have cam-lobe pitting problems, most of them do not; and those little scratches on your cams are not necessarily a precursor to pitting. If you don’t have the extended warranty (and by the tone of your letter, it sounds like you do not), replacing the cams now will cost you the price of the cams and the labor to replace them. If you keep riding and the lobes eventually wear out, replacing the cams then will cost you...the price of the cams and the labor to replace them. The only real gamble with the latter option is that if the lobe wear is dramatic, you also might have to replace some or all of the followers, which could tack as much as $800 onto the repairs. But if you keep riding and the lobes never pit, you’re way ahead of the game.

In the end, you’re faced with a crap shoot, a roll of the dice, and the answer really is a question: Just how lucky are you feeling?

Gee, a rotor

QMy wife has a 2001 Harley-Davidson Fat Boy with 19,000 miles on it. Lately it has taken to wet-sumping (filling the crankcase with oil from the oil tank) when it sits between rides. I know this was common with H-D’s Evo engines but I thought the oil pump on Twin Cam engines was supposed to cure that problem. I’ve heard that on the Twin Cam motor, it’s possible to misalign the oil pump during assembly, which would let oil get into the crankcase, but the motor has never been apart. Is it possible that the pump was assembled incorrectly at the factory and it took five years to start sumping, or should we be looking elsewhere? Don Lindfors

Orange, California

A No matter the reason for your Fat Boy’s wet-sumping, its oil pump will have to be removed and inspected for wear or the accumulation of deposits. The pump is built around two sets of gerotors, which are positive-displacement mechanisms that pump fluids with great efficiency. The two-stage pump is designed to prevent wet-sumping primarily by eliminating the ball-check valve that was the main source of the problem on Evo engines. On FL and Dyna Harleys, the engine oil reservoir is under the transmission, so there is no chance of wet-sumping with them. But on Softails, the oil tank is under the seat, which is much higher than the oil pump, meaning that if no preventive measures were taken, gravity could cause oil to seep around the smaller gerotor (that provides the pressure feed), which is isolated from the larger one (that does the scavenging) by a single separator plate. To prevent such an occurrence, the pump incorporates two separators with a wave-type spring washer between them to keep the plates pushed against their respective gerotors.

Therein is most likely cause of the sumping. If the spring has broken or weakened, oil could seep between the pressure-feed gerotor and its separator plate, then drip down into the crankcase.

There are other possible causes of wet-sumping, including pump misalignment (which isn’t likely, as it would have surfaced when the bike was brand-new) or a failed O-ring. What’s more, because oil is not filtered in Twin Cam engines until after it passes through the oil pump, sumping also could occur if enough contamination has accumulated around the

gerotors to allow seepage past them. But in any event, the pump will have to be removed and disassembled to determine the cause of the wet-sumping.

Armed and single

QA friend and 1 have a debate

going on regarding who invented and debuted the single-sided swingarm.

I say it was Honda in 1985 on the Canadian NR750 and later on the Hawk 650. My friend says it was BMW in the early ’80s. Could you please give us the facts? William Deaton

Albemarle, North Carolina

A If you ignore the fact that quite a few scooters have had singlesided arms for decades (usually smallerdisplacement ones that mount the engine and entire drivetrain on the swingarm) and that a few oddball bikes have also tried that idea over the past century, it’s generally accepted that the French Elf company debuted the modern version of the concept on its innovative GP racebikes in the very early 1980s. BMW was close behind with its shaft-drive variation, and Honda has since used a similar design on the NR750, the Hawk, the VFR Interceptor and the RC30/45 production bikes. But in Honda’s case, even those designs were manufactured under license from Elf. □

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631 -0651; 3) e-mail it to CW1Dean@aol.com; or 4) log onto www.cycleworld.com, click on the “Contact Us” button, select “CW Service” and enter your question. Don’t write a 10page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.