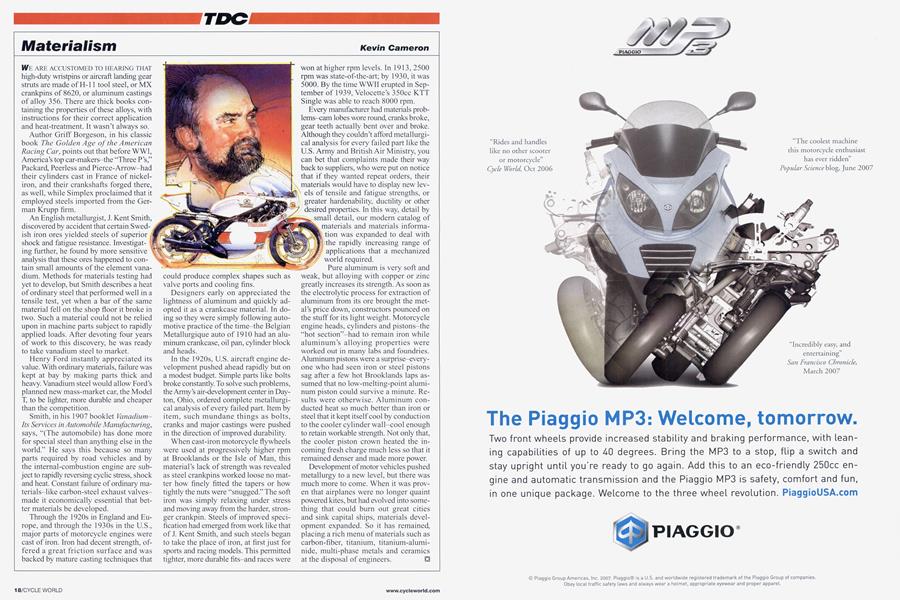

Materialism

TDC

Kevin Cameron

WE ARE ACCUSTOMED TO HEARING THAT high-duty wristpins or aircraft landing gear struts are made of H-11 tool steel, or MX crankpins of 8620, or aluminum castings of alloy 356. There are thick books containing the properties of these alloys, with instructions for their correct application and heat-treatment. It wasn't always so.

Author Griff Borgeson, in his classic book The Golden Age of the American Racing Car, points out that before WWI, America’s top car-makers-the “Three P’s,” Packard, Peerless and Pierce-Arrow-had their cylinders cast in France of nickeliron, and their crankshafts forged there, as well, while Simplex proclaimed that it employed steels imported from the German Krupp firm.

An English metallurgist, J. Kent Smith, discovered by accident that certain Swedish iron ores yielded steels of superior shock and fatigue resistance. Investigat| ing further, he found by more sensitive analysis that these ores happened to contain small amounts of the element vanadium. Methods for materials testing had yet to develop, but Smith describes a heat of ordinary steel that performed well in a tensile test, yet when a bar of the same material fell on the shop floor it broke in two. Such a material could not be relied upon in machine parts subject to rapidly applied loads. After devoting four years of work to this discovery, he was ready to take vanadium steel to market.

Henry Ford instantly appreciated its value. With ordinary materials, failure was kept at bay by making parts thick and heavy. Vanadium steel would allow Ford’s planned new mass-market car, the Model T, to be lighter, more durable and cheaper than the competition.

Smith, in his 1907 booklet VanadiumIts Services in Automobile Manufacturing, says, “(The automobile) has done more for special steel than anything else in the world.” He says this because so many parts required by road vehicles and by the internal-combustion engine are subject to rapidly reversing cyclic stress, shock and heat. Constant failure of ordinary materials-like carbon-steel exhaust valvesmade it economically essential that better materials be developed.

Through the 1920s in England and Europe, and through the 1930s in the U.S., major parts of motorcycle engines were cast of iron. Iron had decent strength, offered a great friction surface and was backed by mature casting techniques that

could produce complex shapes such as valve ports and cooling fins.

Designers early on appreciated the lightness of aluminum and quickly adopted it as a crankcase material. In doing so they were simply following automotive practice of the time-the Belgian Métallurgique auto of 1910 had an aluminum crankcase, oil pan, cylinder block and heads.

In the 1920s, U.S. aircraft engine development pushed ahead rapidly but on a modest budget. Simple parts like bolts broke constantly. To solve such problems, the Army’s air-development center in Dayton, Ohio, ordered complete metallurgical analysis of every failed part. Item by item, such mundane things as bolts, cranks and major castings were pushed in the direction of improved durability.

When cast-iron motorcycle flywheels were used at progressively higher rpm at Brooklands or the Isle of Man, this material’s lack of strength was revealed as steel crankpins worked loose no matter how finely fitted the tapers or how tightly the nuts were “snugged.” The soft iron was simply relaxing under stress and moving away from the harder, stronger crankpin. Steels of improved specification had emerged from work like that of J. Kent Smith, and such steels began to take the place of iron, at first just for sports and racing models. This permitted tighter, more durable fits-and races were

won at higher rpm levels. In 1913, 2500 rpm was state-of-the-art; by 1930, it was 5000. By the time WWII erupted in September of 1939, Velocette’s 350cc KTT Single was able to reach 8000 rpm.

Every manufacturer had materials problems-cam lobes wore round, cranks broke, gear teeth actually bent over and broke. Although they couldn’t afford metallurgical analysis for every failed part like the U.S. Army and British Air Ministry, you can bet that complaints made their way back to suppliers, who were put on notice that if they wanted repeat orders, their materials would have to display new levels of tensile and fatigue strengths, or greater hardenability, ductility or other desired properties. In this way, detail by small detail, our modern catalog of materials and materials informais tion was expanded to deal with the rapidly increasing range of applications that a mechanized world required.

2^ Pure aluminum is very soft and weak, but alloying with copper or zinc greatly increases its strength. As soon as the electrolytic process for extraction of aluminum from its ore brought the metal’s price down, constructors pounced on the stuff for its light weight. Motorcycle engine heads, cylinders and pistons-the “hot section”-had to remain iron while aluminum’s alloying properties were worked out in many labs and foundries. Aluminum pistons were a surprise-everyone who had seen iron or steel pistons sag after a few hot Brooklands laps assumed that no low-melting-point aluminum piston could survive a minute. Results were otherwise. Aluminum conducted heat so much better than iron or steel that it kept itself cool by conduction to the cooler cylinder wall-cool enough to retain workable strength. Not only that, the cooler piston crown heated the incoming fresh charge much less so that it remained denser and made more power.

Development of motor vehicles pushed metallurgy to a new level, but there was much more to come. When it was proven that airplanes were no longer quaint powered kites, but had evolved into something that could burn out great cities and sink capital ships, materials development expanded. So it has remained, placing a rich menu of materials such as carbon-fiber, titanium, titanium-aluminide, multi-phase metals and ceramics at the disposal of engineers. □