SERVICE

PAUL DEAN

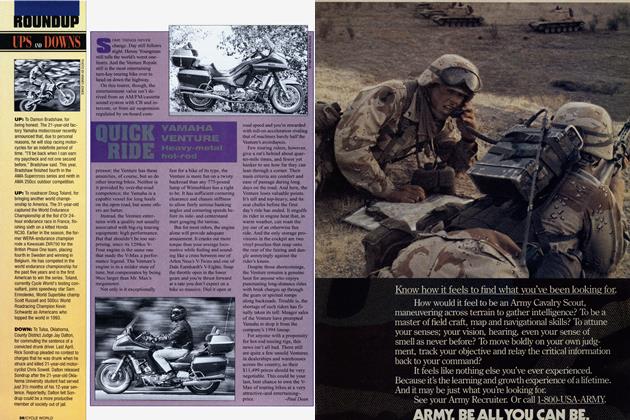

Crossing the line

Q I own an ’01 Suzuki 1200 Bandit S and would like to upgrade to steel-braided front brake and clutch lines. Both the service and parts managers at my local dealer told me not to change the Bandit’s stock three-line front-brake system to a two-line system for three reasons: A two-line system is for racing only and would make little or no difference for street riding; the master cylinder would not flow enough fluid for a two-line system; and with two lines connected to the master cylinder, the line attached closest to the master-cylinder reservoir would receive fluid before the other line, resulting in unequal braking that might cause loss of control. I’m an aircraft mechanic and I think I know a thing or two about hydraulics. Should I go back to school or find a new dealer? William Liening

Savannah, Georgia

A You need to choose Door Number Two, the new-dealer option. The claims made by your current dealer’s managers are so ridiculous that I hardly know where to begin in refuting them.

Actually, their first statement is correct: For street use, a front-brake system with two steel-braided lines would not provide noticeably better braking performance than one with three braided-steel lines. Race tuners generally prefer the two-line setup because it is simpler and allows faster fork and triple-clamp swaps than a three-line arrangement, which requires the removal and reinstallation of the junction block on the lower triple-clamp. Plus, it’s easy for air bubbles to get trapped in the junction block, so bleeding is made a little easier with two uninterrupted lines. The braking feel and stopping power, though, would not be any different than with a three-line arrangement.

But the notion that the master cylinder can’t flow enough fluid for a two-line system is pure nonsense. Once the system is full of fluid and properly bled, the size of the brake lines is inconsequential; they could be as big as sewer pipes and wrap around the entire motorcycle. The only fluid that has to be moved is the small volume needed to23 push the brake pads against the rotors.

If you haven’t already done so, check out the Tech Tip in last month’s Service column and you’ll see an illustrated explanation of the process of moving fluid in a braking system.

Your dealer’s assertion that the brake line closest to the reservoir would get fluid before the other one is equally preposterous. The brake lines don’t “get” fluid when you apply the brakes; they already are completely full, and pressure generated at the master cylinder by squeezing the brake lever is equal throughout the interior of the entire system. Since the only other parts of the system that can move are the caliper pistons, they are pushed out of their bores until the pads make contact with the rotors. And the distance those pistons have to travel is so small that the fluid in the system barely moves.

Besides, your dealer's first statement clearly contra dicts the other two. If two-line systems result in poor braking performance and loss of control, do you think road racers-to whom absolute high-speed control is critical-would use them? Not a chance.

The law of the long arm

Q I have a 1998 VTR1000 Honda Super Hawk that had an unfortu nate meeting with an uninsured Ford Escort. I've caught a bit of the custom izing bug (blame the Discovery Chan nel) and would like to install a singlesided swingarm from a `98 Honda VFR800. The problem I'm having is that the VFR swingarm is about 1.5 inches longer than the stock Super Hawk arm. Will the small difference affect handling much? Mark Windle Dayton, Ohio

A Depends upon how you define "small" and "much." The VFR arm would lengthen the VTR's wheel base to almost 58 inches, and while that certainly is not sufficient to destroy the handling, it would compromise it to a certain extent. If you ride fairly casually and never race, participate in track days or aggressively attack twisty backroads, an inch-and-a-half-longer swingarm would probably not affect the handling enough to warrant any major concerns. But if your riding preferences put a premium on a bike's agility and quickturning capabilities, adding that much swingarm length would likely take some of the joy out of the Super Hawk's excellent sport-riding responsiveness. What's more, you didn't mention what kind of shock you intend to use, but if it's the stock Super Hawk piece, the effective rear-wheel spring and damping rates will be reduced with the longer arm. That could lead to prema ture bottoming and excessive rear-end squat, neither of which is conducive to good handling. Again, if you’re doing this primarily for appearance, no problem; but if crisp handling is an important part of your objective, you may be disappointed with the results.

Over and under

Ql’m new to motorcycles but did a ton of research into used bikes before purchasing my first (a 1994 Honda CBR600F2 in remarkably good condition), and I am curious about a difference in the specifications of the models I considered. The engines in some of the bikes were described as having “shim over bucket” valve adjustment, while others were listed as “shim under bucket.” I think I understand the “shim” part of that description, but could you explain what is meant by “bucket” and the difference between having the shim over or under it? Carl Burke

Kokomo, Indiana

AShim-and-bucket valve adjustment is used on engines that have direct valve actuation-that is, the cam lobes push on the valves without rockers or pivoting followers of any kind. The only permanent medium between lobe and valve is the bucket-so named because of its appearance but that also is referred to as the tappet or valve lifter-which fits over the top of the valve stem. To allow adjustment of the valve clearance, each bucket is fitted with a shim, either under it or on top of it, that can be exchanged for a thicker or thinner one.

As shown in the accompanying illustration, an under-bucket shim is only slightly larger in diameter than the valve stem and sits in a deep recess in the underside of the bucket. An over-bucket shim is larger and resides in a shallow recess on the top of the bucket. Since the over-bucket shim also serves as the contact surface for the cam lobe, it must be at least as wide as the lobe to prevent uneven wear of both components.

There are advantages and disadvantages of both types. Over-bucket shims are much easier to remove and replace; using a special tool, you can depress each valve far enough to allow its shim to be lifted out of the bucket and another slipped in. But because the shim is held in place only by the shallow recess in the bucket and the tiny clearance between shim and cam lobe, it can be spit out of the bucket at higher rpm, especially if the engine revs high enough to float the valves. This occasionally happened on some bikes in the 1970s and ’80s, prompting most manufacturers to switch to the under-bucket type of shim. But while those shims, tucked securely under their buckets, will never fly out at any rpm, they are much more difficult and time-consuming to change. The cams must first be removed to gain access to the shims, then reinstalled so the clearance can be checked. And if the replacement shim does not yield the desired clearance, the cam has to be removed once again so a thicker or thinner one can be tried.

A little cranky-panky

QAS a former mechanic (many years ago!), I have a technical question. I recently purchased a Kawasaki Ninja 650R, which has a 180-degree crankshaft, and I’m concerned with the firing sequence of such an arrangement. Does it have two power pulses 180 degrees apart followed by 540 degrees of crank rotation prior to the next cycle? If so, the “staggered” firing sequence isn’t detectable in the exhaust note. The engine runs great and has gobs of low-end and midrange power. I’m just curious about the degree of imbalance inherent in such a setup. There is some “buzziness” at certain rpm but nothing like I’ve experienced on old Triumphs with 360-degree cranks. Am I right about the 650R’s power cycle or is there something I’m missing? Larry Fuller

Poulsbo, Washington

A Your description of the Ninja’s 180-540 firing sequence is right on the money, but the 65 OR’s engine is far from the first to use a 180-degree crankshaft. Quite a few other motorcycles-including countless Honda Twins of the ’60s and ’70s, and even Kawasaki’s long-standing Ninja 500R-are parallel-Twins with 180-degree cranks.

So the 650R’s engine is not exploring any new design territory.

In fact, a parallel-Twin with a 180> degree crank has better balance than one with a 360-degree crank. On the latter, both pistons rise and fall together, and the vibration caused by them simultaneously having to stop and restart at Top Dead Center and Bottom Dead Center is largely offset by the counterweights on the crankshaft. I say “largely” because it is impossible to fully offset the reciprocating (back-and-forth) imbalance of the pistons with the rotating imbalance of the crank. Plus, any time the crank’s spinning counterweights are not at TDC or BDC, they create a separate imbalance of their own.

Homebrevvs

I After recently reading about oil-stain removal using Shout in your June-issue Homebrews section, I wanted to impart some related knowledge about removing oil/grease stains from clothing. If you get garage grease or oil on some of your finer items of attire, simply put any white-pastebased toothpaste on an old toothbrush and scrub it in! Don’t use the gels, as they don’t work nearly as well; your standard-fare Colgate or Crest pastes are preferable. Once the paste is on the brush, put a little water on it to moisten it up and help the mixture sink into the stain during the initial scrub. Just allow it to sit for a few minutes and then toss it into the wash. Works wonders!

“Mojo” Povoden Whistler, British Columbia, Canada

Plus, you won’t have to worry about any troublesome plaque buildup on your garments, either. Thanks for the tip, Mojo.

But on a 180-degree parallel-Twin, the pistons are always working in opposition, one reaching TDC while the other is at BDC, and vice versa. Consequently, the deceleration/acceleration events of each piston are effectively canceled by those of the other. Ditto for the effect of the two sets of crankshaft counterweights, which obviously are also phased 180 degrees from one another.

Nevertheless, a 180-degree parallelTwin does emit some vibration, caused by what is called a “rocking couple.” Imagine what happens when one pistonthe right one, say-reaches TDC and the other reaches BDC. The abrupt deceleration of the right piston tries to yank the engine upward, while the deceleration of the left one wants to yank it downward. The net result is that the engine wants to rotate counterclockwise along a longitudinal axis. Then, 180 degrees of crank rotation later, the reverse happens and > the engine tries to rotate clockwise when the right piston hits BDC and the left one reaches TDC. So, twice in each full crankshaft revolution, the entire engine tries to rotate in this manner, first in one direction and then the other. The result is a high-frequency oscillation, which is the buzziness you feel on your 650R.

Feedback Loop'

Ql with own about a 2005 10,000 Suzuki miles Hayabusa on the odometer. As I was riding home from work recently, I went to downshift and found that the shift-lever pivot bolt had unscrewed itself and the whole gearshift was gone. Well, not completely gone, but dangling below my bike. I got safely off the road and temporarily repaired it so I could get home to lock it down and lube it correctly. I had ridden to Deal’s Gap two weeks prior to this and realized how much I would have missed that downshift on “The Dragon.” I have spoken with other 'Busa owners who have had the same problem. It is an easy fix with snapring pliers and Loctite. Stuart Grant Kingsland, Georgia

A Good info, Stuart. I’m sure quite a few Hayabusa owners will be eternally grateful for your advice in preventing what could be a very dangerous situation.

No shift, Sherlock

QI have owned a 1999 Harley-

Davidson FLHR Twin Cam Road King since new. From the beginning, the transmission has constantly missed shifts going up or down between first and second gears, and between third and fourth. This happens more so between first and second, especially if I’m hard on the throttle. I’ve had two different factory dealerships look at it four times, and the shift drum and forks have been replaced, but it still does it. I do not want to change to an aftermarket transmission and I do not want a sixspeed. What is causing this problem and how do I fix it using Harley transmissions? Dimitri Manesis

Novato, California

A Your Road King’s transmission has been subjected to seven years of missed shifts and four unsuccessful repairs by two dealerships; after all that, I can’t say for certain what the problem might be. But gearbox problems like > those you describe usually are due to a misadjusted shifter pawl-a claw-like arm on the shift linkage that turns the shift drum. Pushing the shift lever up or down moves the pawl one way or the other so it catches on one of the cam pins on the end of the shift drum, causing the drum to rotate and engage the next gearset. When you let up on the lever after the shift, the pawl returns to the centered position to await the next shift up or down.

Problems arise when the pawl is not centered on any two cam pins before a shift is attempted. When that happens, the pawl will either rotate the shift drum too far during the next attempted shift, or too little. Either way, the shift is likely to be rejected immediately or shortly thereafter.

Adjusting the shifter pawl is a fairly simple task if you’re a half-decent backyard mechanic. The pawl adjuster is on the left side of the transmission case, just above the shift shaft, and involves a locknut and a hex-head screw. With the transmission in third gear (no other gear will suffice), loosen the locknut and turn the screw slightly one way or the other until the pawl is centered on the two cam pins as shown in the accompanying illustration. You have to be very precise when making this adjustment to get equal pin-to-pawl clearance on both sides or the ill-shifting problem is likely to continue. If you need more help in making this adjustment yourself, buy or borrow a factory shop manual for your Road King. If you plan to keep the bike much longer, the manual will prove to be a worthwhile investment. U

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/6310651; 3) e-mail it to CW1Dean@aol.com; or 4) log onto www.cycleworld.com, click on the “Contact Us” button, select “CW Service” and enter your question. Don’t write a 10page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

View Full Issue

View Full Issue