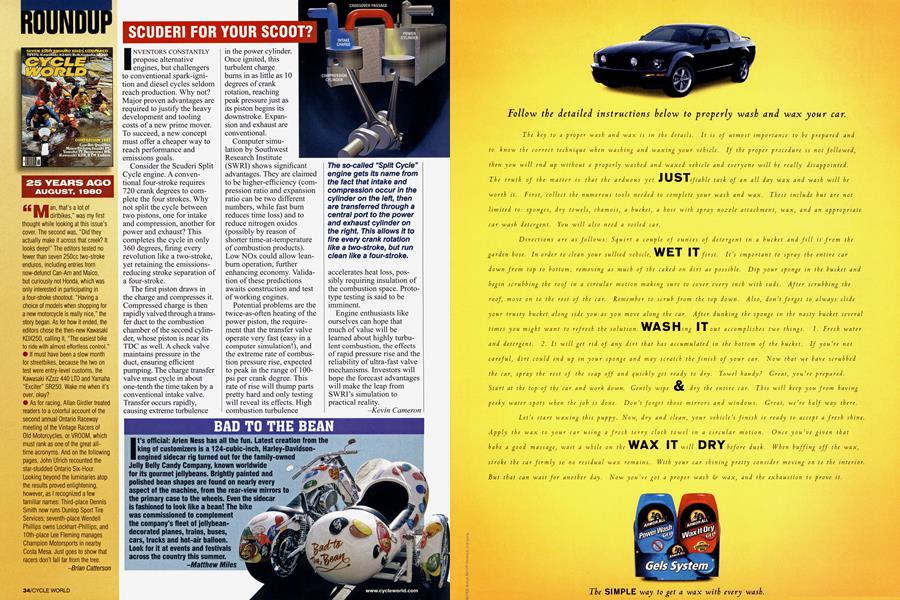

SCUDERI FOR YOUR SCOOT?

INVENTORS CONSTANTLY propose alternative engines, but challengers to conventional spark-ignition and diesel cycles seldom reach production. Why not? Major proven advantages are required to justify the heavy development and tooling costs of a new prime mover. To succeed, a new concept must offer a cheaper way to reach performance and emissions goals.

Consider the Scuderi Split Cycle engine. A conventional four-stroke requires 720 crank degrees to complete the four strokes. Why not split the cycle between two pistons, one for intake and compression, another for power and exhaust? This completes the cycle in only 360 degrees, firing every revolution like a two-stroke, yet retaining the emissionsreducing stroke separation of a four-stroke.

The first piston draws in the charge and compresses it. Compressed charge is then rapidly valved through a transfer duct to the combustion chamber of the second cylinder, whose piston is near its TDC as well. A check valve maintains pressure in the duct, ensuring efficient pumping. The charge transfer valve must cycle in about one-tenth the time taken by a conventional intake valve. Transfer occurs rapidly, causing extreme turbulence

in the power cylinder. HH| Once ignited, this turbulent charge bums in as little as 10 HHj degrees of crank |H rotation, reaching peak pressure j ust as * * its piston begins its downstroke. Expansion and exhaust are . conventional.

Computer simulation by Southwest Research Institute (SWRI) shows significant advantages. They are claimed to be higher-efficiency (compression ratio and expansion ratio can be two different numbers, while fast bum reduces time loss) and to reduce nitrogen oxides (possibly by reason of shorter time-at-temperature of combustion products). Low NOx could allow leanbum operation, further enhancing economy. Validation of these predictions awaits construction and test of working engines.

Potential problems are the twice-as-often heating of the power piston, the requirement that the transfer valve operate very fast (easy in a computer simulation!), and the extreme rate of combustion pressure rise, expected to peak in the range of 100psi per crank degree. This rate of rise will thump parts pretty hard and only testing will reveal its effects. High combustion turbulence

accelerates heat loss, possibly requiring insulation of the combustion space. Prototype testing is said to be imminent.

Engine enthusiasts like ourselves can hope that much of value will be learned about highly turbulent combustion, the effects of rapid pressure rise and the reliability of ultra-fast valve mechanisms. Investors will hope the forecast advantages will make the leap from SWRI’s simulation to practical reality. -Kevin Cameron

View Full Issue

View Full Issue