Tireless metals

TDC

Kevin Cameron

MOTORCYCLES DEPEND ON THE PROPERties of materials, and one especially intense material application is in ball and roller bearings—used in con-rods, crank main bearings, gearboxes, wheels and elsewhere. For every turn of a shaft supported by rolling bearings, each of the rolling elements rotates many times, accumulating fatigue cycles rapidly. Why don’t they develop cracks promptly and break up?

Rolling bearings are as old as the day when someone first chose to roll rather than carry a heavy object. Tower mills of the 14th century rotated on large rollers to face the wind. Later, da Vinci pictured rolling bearings in his notes, and Galileo described the use of a cage to properly space adjacent rolling elements. Highcapacity rolling bearings would have to await the coming of quantity production of steel after 1860. Only steel could long sustain the repeated highly concentrated loads that occur in the point and line contact of balls or rollers. Friedrich Fischer, working in Germany in 1883, devised a practical way to mass-produce accurate, low-cost steel balls, and the safety bicycle craze of the 1890s gave them a huge market.

Steel must be hardened to prevent flattening of rollers and denting of races. Think of the terrible forces on the few balls or rollers supporting the steering head of your motorcycle during braking. Carbon-steel is hardened by heat treatments that generate myriad particles of iron carbide, acting as keys to prevent relative motions between layers of iron atoms. Yet the harder the steel is made, the more brittle it becomes. Being too hard to yield even slightly, it can only break under load.

Help was at hand. In the 1880s, the world’s navies were evaluating and adopting tough, shell-resisting nickelsteel armor. This focused attention on the ability of alloying elements such as nickel and chromium to strengthen steel without making it as brittle as fully hardened carbon-steel. By dissolving a small percentage of some other metal in the steel, the slightly different diameter of the added atoms created local barriers to slip between atomic planes. This is “solution hardening.” A nickel-steel, for example, made possible the toughness needed for bicycle chain drives. A tiny amount-a percent or so-is all it takes to have a marked strengthening, toughening effect.

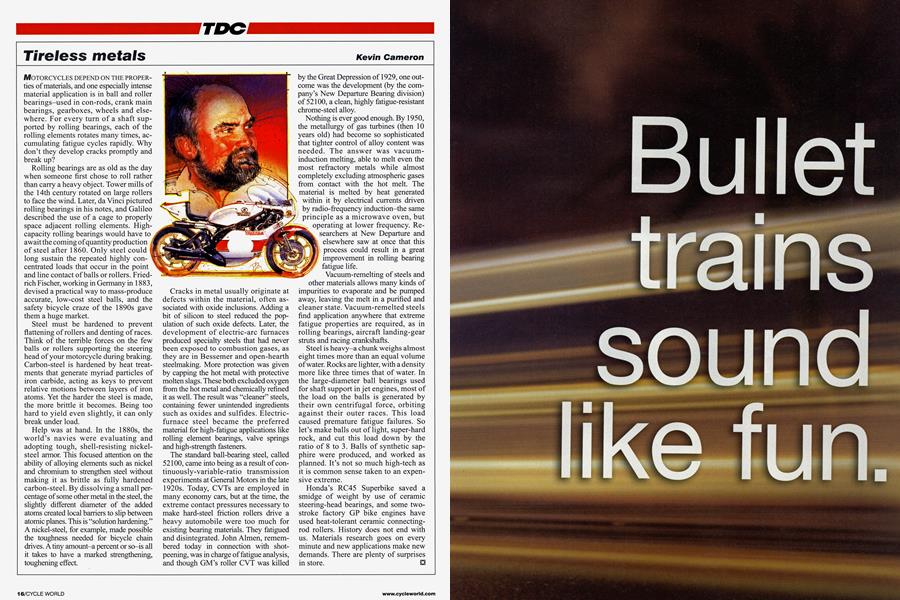

Cracks in metal usually originate at defects within the material, often associated with oxide inclusions. Adding a bit of silicon to steel reduced the population of such oxide defects. Later, the development of electric-arc furnaces produced specialty steels that had never been exposed to combustion gases, as they are in Bessemer and open-hearth steelmaking. More protection was given by capping the hot metal with protective molten slags. These both excluded oxygen from the hot metal and chemically refined it as well. The result was “cleaner” steels, containing fewer unintended ingredients such as oxides and sulfides. Electricfurnace steel became the preferred material for high-fatigue applications like rolling element bearings, valve springs and high-strength fasteners.

The standard ball-bearing steel, called 52100, came into being as a result of continuously-variable-ratio transmission experiments at General Motors in the late 1920s. Today, CVTs are employed in many economy cars, but at the time, the extreme contact pressures necessary to make hard-steel friction rollers drive a heavy automobile were too much for existing bearing materials. They fatigued and disintegrated. John Almen, remembered today in connection with shotpeening, was in charge of fatigue analysis, and though GM’s roller CVT was killed

by the Great Depression of 1929, one outcome was the development (by the company’s New Departure Bearing division) of 52100, a clean, highly fatigue-resistant chrome-steel alloy.

Nothing is ever good enough. By 1950, the metallurgy of gas turbines (then 10 years old) had become so sophisticated that tighter control of alloy content was needed. The answer was vacuuminduction melting, able to melt even the most refractory metals while almost completely excluding atmospheric gases from contact with the hot melt. The material is melted by heat generated within it by electrical currents driven by radio-frequency induction-the same principle as a microwave oven, but operating at lower frequency. Researchers at New Departure and elsewhere saw at once that this ! process could result in a great improvement in rolling bearing fatigue life.

Vacuum-remelting of steels and other materials allows many kinds of impurities to evaporate and be pumped away, leaving the melt in a purified and cleaner state. Vacuum-remelted steels find application anywhere that extreme fatigue properties are required, as in rolling bearings, aircraft landing-gear struts and racing crankshafts.

Steel is heavy-a chunk weighs almost eight times more than an equal volume of water. Rocks are lighter, with a density more like three times that of water. In the large-diameter ball bearings used for shaft support in jet engines, most of the load on the balls is generated by their own centrifugal force, orbiting against their outer races. This load caused premature fatigue failures. So let’s make balls out of light, super-hard rock, and cut this load down by the ratio of 8 to 3. Balls of synthetic sapphire were produced, and worked as planned. It’s not so much high-tech as it is common sense taken to an expensive extreme.

Honda’s RC45 Superbike saved a smidge of weight by use of ceramic steering-head bearings, and some twostroke factory GP bike engines have used heat-tolerant ceramic connectingrod rollers. History does not end with us. Materials research goes on every minute and new applications make new demands. There are plenty of surprises in store. □