Anything but smooth

TDC

Kevin Cameron

SOMEWHERE IN HIGH SCHOOL, STUDENTS sit through a brief description of how the four-stroke cycle works. Thus we learn (if paying attention) intake, compression, power, exhaust. Those of us who later become at least part-time students of the internal-combustion engine are left to wonder what keeps the engine going through intake, compression and exhaust when power is given on only one stroke out of four. The correct answer is that the kinetic energy stored in the flywheel is what keeps the engine going when combustion pressure isn’t actively pushing on the piston.

This means that the engine cycle is like the bank account of a weekly employee. The power stroke is the deposit of the paycheck on Friday, and that, plus what’s already in the bank is the flywheel that keeps the groceries coming and the bills paid the rest of the week. Sometimes, as we all know, the energy in that flywheel can dwindle away to be pretty small. The result is the occasional near-stall when we have to search in jacket pockets and under sofa cushions to pay for the pizza delivery.

What this means is that the actual speed of the crankshaft is at a maximum as the power stroke ends, and that it slows down steadily through exhaust, intake and compression until the next “deposit” of energy is made to kick it back up to peak again.

Okay, that’s a story about single-cylinder engines. As we add cylinders, crankshaft rotational speed smoothes out, right? Yes, it does, but at the same time we are sensibly reducing the engine’s flywheel mass to just a bit more than it needs to maintain a smooth idle. A Single naturally needs mighty mill-wheels to keep it going, but by the time we get to three or four cylinders, nothing like a round flywheel remains-j ust the bare crankshaft and its counterweights. This means that there is still a fair amount of crank speed variation.

Who cares? We can see that there’s a spring drive in most motorcycle clutches to smooth out this crank speed variation so that the gearbox doesn’t have to endure a series of hammer blows from the cylinder firings. Those springs or rubber elements in the clutch outer hub handle it.

But wait, there are no such flexible elements in the cam drive. That means that crank speed variation will travel through the chain, belt or gears driving the cams, and that something like crank speed variation (minus whatever is lost in translation) will appear at the cam lobes.

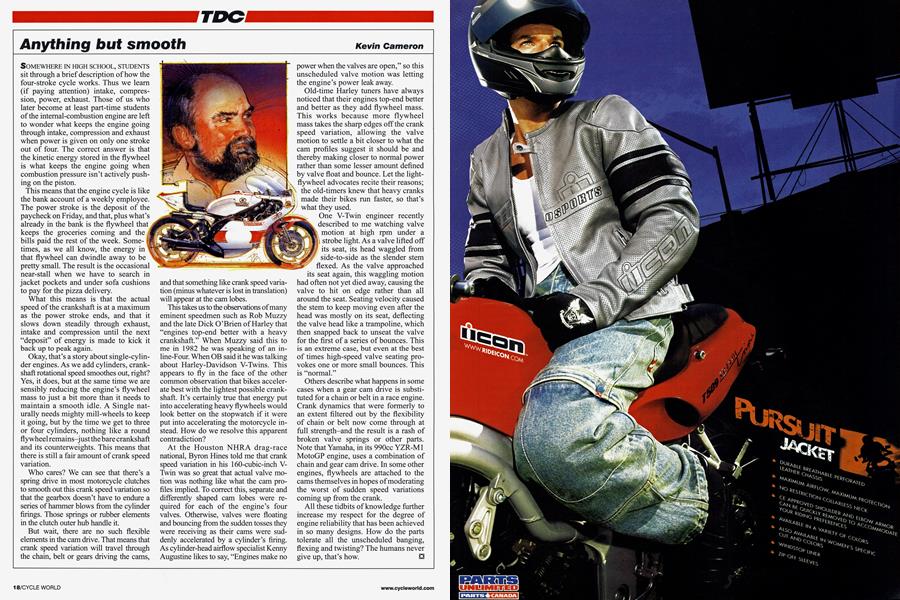

This takes us to the observations of many eminent speedmen such as Rob Muzzy and the late Dick O’Brien of Harley that “engines top-end better with a heavy crankshaft.” When Muzzy said this to me in 1982 he was speaking of an inline-Four. When OB said it he was talking about Harley-Davidson V-Twins. This appears to fly in the face of the other common observation that bikes accelerate best with the lightest possible crankshaft. It’s certainly true that energy put into accelerating heavy flywheels would look better on the stopwatch if it were put into accelerating the motorcycle instead. How do we resolve this apparent contradiction?

At the Houston NHRA drag-race national, Byron Hines told me that crank speed variation in his 160-cubic-inch VTwin was so great that actual valve motion was nothing like what the cam profiles implied. To correct this, separate and differently shaped cam lobes were required for each of the engine’s four valves. Otherwise, valves were floating and bouncing from the sudden tosses they were receiving as their cams were suddenly accelerated by a cylinder’s firing. As cylinder-head airflow specialist Kenny Augustine likes to say, “Engines make no power when the valves are open,” so this unscheduled valve motion was letting the engine’s power leak away.

Old-time Harley tuners have always noticed that their engines top-end better and better as they add flywheel mass. This works because more flywheel mass takes the sharp edges off the crank speed variation, allowing the valve motion to settle a bit closer to what the cam profiles suggest it should be and thereby making closer to normal power rather than some lesser amount defined by valve float and bounce. Let the lightflywheel advocates recite their reasons; the old-timers knew that heavy cranks made their bikes run faster, so that’s what they used.

One V-Twin engineer recently described to me watching valve motion at high rpm under a \ strobe light. As a valve lifted off its seat, its head waggled from side-to-side as the slender stem flexed. As the valve approached its seat again, this waggling motion had often not yet died away, causing the valve to hit on edge rather than all around the seat. Seating velocity caused the stem to keep moving even after the head was mostly on its seat, deflecting the valve head like a trampoline, which then snapped back to unseat the valve for the first of a series of bounces. This is an extreme case, but even at the best of times high-speed valve seating provokes one or more small bounces. This is “normal.”

Others describe what happens in some cases when a gear cam drive is substituted for a chain or belt in a race engine. Crank dynamics that were formerly to an extent filtered out by the flexibility of chain or belt now come through at full strength-and the result is a rash of broken valve springs or other parts. Note that Yamaha, in its 990cc YZR-M1 MotoGP engine, uses a combination of chain and gear cam drive. In some other engines, flywheels are attached to the cams themselves in hopes of moderating the worst of sudden speed variations coming up from the crank.

All these tidbits of knowledge further increase my respect for the degree of engine reliability that has been achieved in so many designs. How do the parts tolerate all the unscheduled banging, flexing and twisting? The humans never give up, that’s how.

View Full Issue

View Full Issue