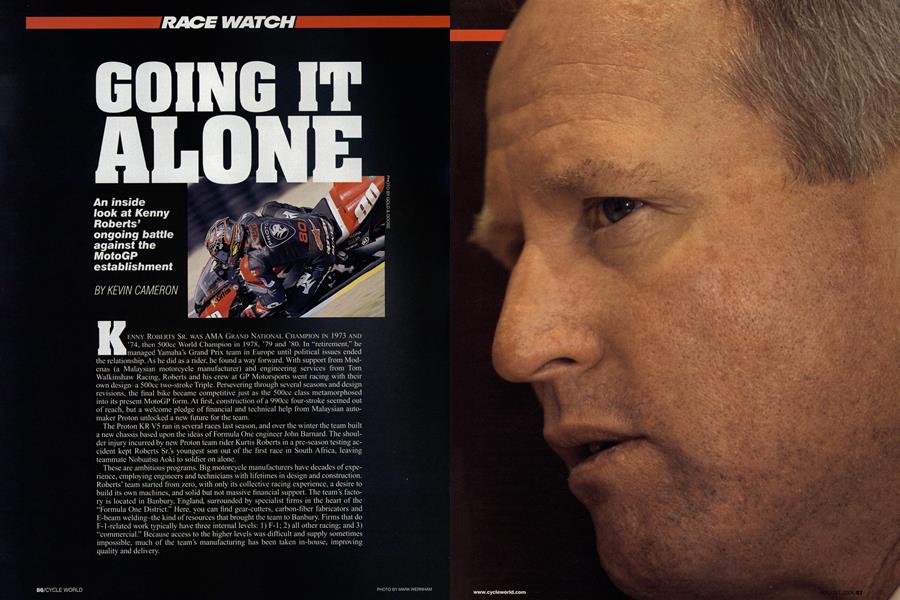

GOING IT ALONE

RACE WATCH

An inside look at Kenny Roberts’ ongoing battle against the MotoGP establishment

KEVIN CAMERON

KENNY ROBERTS SR. WAS AMA GRAND NATIONAL CHAMPION IN 1973 AND '74, then 500cc World Champion in 1978, '79 and '80. In "retirement," he managed Yamaha's Grand Prix team in Europe until political issues ended the relationship. As he did as a rider, he found a way forward. With support from Modenas (a Malaysian motorcycle manufacturer) and engineering services from Tom Walkinshaw Racing, Roberts and his crew at GP Motorsports went racing with their own design—a 500cc two-stroke Triple. Persevering through several seasons and design revisions, the final bike became competitive just as the 500cc class metamorphosed into its present MotoGP form. At first, construction of a 990cc four-stroke seemed out of reach, but a welcome pledge of financial and technical help from Malaysian auto maker Proton unlocked a new future for the team.

The Proton KR V5 ran in several races last season, and over the winter the team built a new chassis based upon the ideas of Formula One engineer John Barnard. The shoulder injury incurred by new Proton team rider Kurds Roberts in a pre-season testing accident kept Roberts Sr.’s youngest son out of the first race in South Africa, leaving teammate Nobuatsu Aoki to soldier on alone.

These are ambitious programs. Big motorcycle manufacturers have decades of experience, employing engineers and technicians with lifetimes in design and construction. Roberts’ team started from zero, with only its collective racing experience, a desire to build its own machines, and solid but not massive financial support. The team’s factory is located in Banbury, England, surrounded by specialist firms in the heart of the “Formula One District.” Here, you can find gear-cutters, carbon-fiber fabricators and E-beam welding-the kind of resources that brought the team to Banbury. Firms that do F-l-related work typically have three internal levels: 1) F-l; 2) all other racing; and 3) “commercial.” Because access to the higher levels was difficult and supply sometimes impossible, much of the team’s manufacturing has been taken in-house, improving quality and delivery.

As in F-l, teams reveal few specifications. The Proton KR engine has five cylinders in Vee form, as does the successful Honda RC211V The practical reason for choosing five cylinders is that such an engine has nearly the same cylinder size as did 750cc four-cylinder Superbike engines. For Honda, the starting point was the RC45. For Proton, design was loosely based on Kawasaki race

engines, using the experience of “Mr. Superbike,” Rob Muzzy. Engine detail design was by John Magee. The first engine/chassis design was really a test mule that also raced. Its purpose was to quickly map out the basics of four-stroke GP racing-to get the information that normally only factories have. To position the engine experimentally, it had to be made small enough to be moved around in the > space between front and rear wheels. That dictated a narrow cylinder bank angle. Honda chose 75.5 degrees, probably because that allowed the fifth cylinder (the center front) to compensate for the imbalance of narrowing a 90-degree VFour. The Proton required a balance shaft to smooth it sufficiently so as not to

crack its aluminum chassis. We visited the team on the Thursday after the first GP of this year. Kenny conducted our tour himself, meanwhile candidly commenting on everything. A GP bike is more than engine and chassis.

Up a metal stairway, overlooking the machining and fabricating floor, is the electronics area. Here, wire harnesses are made and tested, control software is written and the team’s vehicle dynamics model is run. A feature of GP bike wiring is the use of weatherproof mil-style connectors. Lots of pins to be soldered perfectly.

Down below, a swingarm was under construction, jigged onto a heavy baseplate. The novel feature of the new chassis is that all of its elements are machined-there are no castings or extrusions. The goal is higher dimensional accuracy than has previously been possible. Some years ago, Muzzy called me over to one of his Superbikes, indicating the steering head. “We machine these ourselves to put all the pivots where they should be,” he said, showing that the head bearings had to be bored almost Vs-inch off-center in the headstock pipe to achieve this. Small errors, big effects. Another point is that engines are more complex now, with rigidly attached carbon-fiber airboxes that must slot accurately into the space provided for them-without hours of hand fitting. Top teams must have strict parts interchangeability.

The new chassis employs a single, central ram-air inlet, whose square duct surrounds the streamline-section steering-head tube. Every part but the side beams bears the fine toolmarks of the shop’s Deckel Maho five-axis machining center. And those side beams? They are machined by “another process,” at least as precise as rotary cutting. Many functions are integrated into the chassis, reducing the number of tasks necessary when changing engines. During WWII, both sides modularized their aircraft engines in this way as “QECs”-Quick Engine Change units-with all accessories, wiring and plumbing already in place. With the short practice time available at GPs, it pays to think ahead.

The manufacture of complex structures from machined elements came initially from aerospace, where in the 1950s jet fighters evolved from sheetmetal to precision-machined parts, bringing about the CNC revolution in the process. In F-l today, gearcases are made as separate machined elements, joined by welding into a whole. The result is lighter and stronger than an equivalent cast case.

The KR V5’s steel crankshaft has three crankpins, arranged at an odd spacing. One account suggests 120 degrees, but this engine’s musical sound indicates something closer to an even firing interval than that would permit. Or, firings might be grouped into three pulses. After the second GP, the firing order was changed to a less “Big-Bang” arrangement, but leaving the crankpins where they were. As an example, an outer crankpin (carrying two con-rods) might receive one firing impulse at 0 degrees and then the other 60 degrees later. Or, it could fire at 0 degrees and then the forward cylinder 420 degrees later-just as with a 60-degree V-Twin. Engineers like even firing intervals. They cut peak drivetrain loads and excite the crankshaft with a single firing frequency.

The con-rods are beautiful little machined titanium plain-bearing pieces, and join to light, short pistons that are perhaps 32mm high. As in Kawasaki Superbike engines, most of the combustion volume is in these pistons, with crown

material outside the sunken quatrefoil of the valve cutouts being raised to become squish. Air above these squish regions is rapidly squirted out as the piston approaches the head to within .025 of an inch at TDC. The resulting rapid air motion helps to further “stir” the fuel-air mixture, and provides combustion-accelerating turbulence.

Four titanium valves per cylinder are driven by fairly large conventional inverted-bucket tappets, and returned by metal springs. The tappets are black-surely a hard-coating intended both to prevent cam-to-tappet galling and to resist the strong tilt force that results when the cam lobe pushes against it far off-center. The gear-driven cams are hollow and light, and their lobes tell a tale. These lobes have a large nose radius that indicates fairly long cam timing. It is known that this engine currently has a “hole” in its torque curve. The usual cause of this is significant valve overlap-beginning to open the intake valves some time before the exhausts have finally closed. If during overlap a positive exhaust pipe wave returns to the cylinder, it will delay the intake stroke by blowing exhaust gas into the combustion chamber and possibly filling the intake port as well. In the rpm zone where this happens, torque drops.

The three-cylinder Aprilia “Cube” shows what happens when F-l technology is uncritically applied to motorcycles. Its power is abrupt, and although the bike has been fast in a straight line, it is not competitive. F-l cars have abundant traction that can handle such power. Motorcycles have very little. As the motorcycle must slow more for turns, it is imperative that it uses all available grip during off-corner acceleration. That requires the engine’s torque curve to be smooth as butter, and free of sudden torque rises of the kind that contributed to Kurds’ fiery testing crash.

Cam timing is not a free choice-the designer may be unable to reduce valve overlap even if he would like to. As compared with F-l-style pneumatic closers, metal springs reduce the maximum possible valve acceleration. Opening and closing the valves with this lower acceleration requires either valve lift to be reduced or cam timing to be made longer.

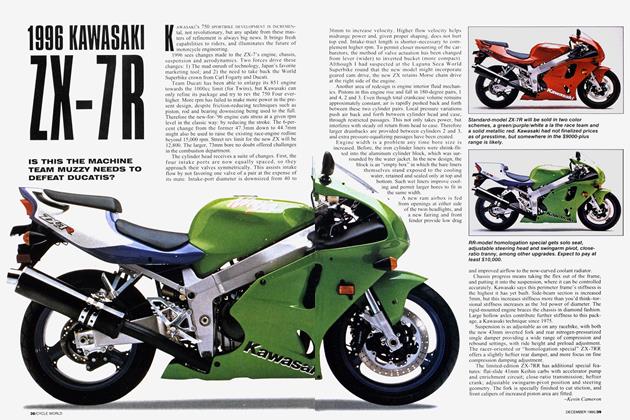

These Superbike-derived V-Fives probably have bore and stroke dimensions close to 74.0 x 46.0mm. The Proton, being a “young” design, would combine middling cylinder filling and combustion, resulting in something like 190 horsepower at close to 14,000 rpm. Roberts Sr. mentioned possibly building a “long-stroke” version next. Why? He didn’t say, but in 1996 Kawasaki shifted from a 71.0 x 47.3mm engine to a largerbore, shorter-stroke 73.0 x 44.7mm. This is a classic bind. Shortening the stroke allows the engine to rev higher-an important step toward making more power. But enlarging the bore makes the combustion chamber thinner, slowing combustion so the engine loses torque on the top end. Some of the lost top end can be regained by reducing the compression ratio, opening up the combustion chamber so it can burn better on top. But the compression reduction also kills the engine’s acceleration. It took two years’ development for Kawasaki’s new engine to match the power of the old one. “Having it all” is a grand goal, but where is the perfect compromise?

The aluminum crankcase is substantial and includes the gearbox in unit-something Kenny says may in the future change. Coated aluminum wet cylinder liners are set into the upper case. Excessive lightness has been a problem in other engines. Vibration and chassis stresses conspire to make cylinders leak and gearboxes malfunction. Rigidity is good.

At one point, we heard the ascending note of an engine on test, so we went straight to the dyno room. Magee was at the dyno controls and the team’s veteran test engineer, Bud Aksland, was among the group. Shortly, two technicians began to remove the pipes from the hot engine. A shorter set awaited the next test. An integral intake airbox attaches in the engine’s Vee, made from razor-thin black carbon-fiber.

Airbox volume is hard to come by, so all the space below the injector bellmouths is included in it. Airboxes were a serious inconvenience before electronic fuel-injection, but with it, “jetting” changes are made by laptop-no disassembly required.

Currently, the crew is pondering a deficit from the predicted horsepower for this engine. At Lotus (now a Proton subsidiary), friction was measured by driving a non-firing engine with an electric motor. “Frictions are good,” Kenny said. “So it’s something else.”

I admired the nice dyno setup, but there is only one. I saw nine at Aprilia’s racing department four years ago. How many does Honda have? How many shifts does it operate? This is the difference between a specialty shop and major industry.

In a small room off the main floor, we looked at gearbox parts. This is, naturally, a cassette design that can be R&Red without splitting the cases. The hefty gears are hard-cut from pre-heat-treated stock by Xtrac. Shift forks are as beautifully detailed as any in F-l, driven by a honeycombed steel shift drum 2 inches long.

Next, the large parts department-aisles of tall, racked bins full of everything needed to build the bikes. Keeping track of suppliers, drawings, computer files, stock ordered and on-hand is a full-time job for someone. Here are beautiful castings, gleaming gears, iridescent machined titanium bits. The factory is small, but the undertaking is huge.

What lies ahead? Roberts was optimistic that the new chassis will soon show its advantages. Next year, the fuel allowance will be reduced from the present 24 liters to 22-a change already delayed once by manufacturer pressure (bikes have run out of gas on the off lap). He seemed confident in the rumor (one of many) that Honda will field a more efficient three-cylinder engine. A Six! Elliptical pistons! A balsacrankshaft! A highly placed source at Honda said only, “Don’t believe everything you read.” There is pressure to cut

speeds by dropping displacement from 990 to 900cc in three years. If so, it means either another top-to-bottom redesign or running an overweight engine.

It is particularly frustrating for Roberts’

GP Motorsports, as a small and relatively inexperienced manufacturer, to be at the mercy of rules changes that the majors take in stride. By the time the KR3 delivered on its promise, the rules had changed. Now, as they repeat that struggle with their V-Five, the 22-liter rule may require some fresh revolution. As was recently remarked by Ducati Corse’s Claudio Domenicali, it would be nice to have the resources to explore alternatives. The smaller the team, the more time they must spend bailing their boat, and the less energy they have with which to row it. Honda is admired and feared for its strength in this area.

On the other hand, it is known that other teams have the same problems of supply that Roberts faces, and must often wait for critically needed items. Racing has become so highly specialized that certain suppliers are the only source for what they provide.

Roberts exploits two areas of strength. First, management and staff are experienced racing people. Whatever the bike, it is experience that makes it work on the track. Second, the team is not limited to designs that resemble a saleable product-racebikes are all they make. This allows them (even forces them) to consider radical solutions.

Having no sales can also hurt.

The right tire brand cuts lap times more than does a year of engine development. Hmm, so you want to use my company’s tires? Well, how many streetbikes did you say you sell each year? And how many have my tires on them? Zero, you say? Goodbye. Last year, Team KR was on the rapidly improving Bridgestones, but that deal flew away. This year, they race on Dunlops. Roberts and Dunlop hope each will benefit from a monogamous relationship. Michelin remains the heavy hitter.

Roberts is a racer. Racers use all their considerable energy and intelligence to get the maximum out of what they have to work with. That’s just what he’s doing in MotoGP. □

View Full Issue

View Full Issue