SERVICE

Paul Dean

Rhinos vs. Schwinns

I am curious about what makes some bikes more manageable than others in slow-speed, tight situations. My H-D Road King, fully loaded with two-up, feels like a rhinoceros when I attempt a U-turn on a narrow lane. When I climb aboard my buddy's BMW R1150RT, I can maneuver around a gas pump like I was on a Schwinn. Does the bike's center of gravity have any bearing? If so, why don't manufacturers offer this info as part of the bike's specs? Is it that difficult to calculate as a simple heightfrom-the-pavement number? This is not an academic question. As time passes, (I've been riding since 1959), this becomes a more meaningful factor when considering a new scoot. Steven Faller Union, Maine

The handling characteristics of any motorcycle-whether at low speeds, high speeds or anywhere in between-involve much more than the bike s center of gravity. The eg is very important, of course, but so are many other design aspects, including steering geometry, steering mass, weight distribution, wheelbase, tire construction and a factor commonly referred to as mass centralization-placing as much of a bike ’s mass as possible as close to its center of gravity as possible. How any given bike handles is the net effect of how all these factors work together.

Your Road King is a heavy bike, especially two-up, with a long wheelbase, wide tires and relatively slow steering geometry. All these are factors that add up to less-than-nimble handling.

In a vertical plane, the bike ’s mass is carried reasonably low, since the narrowness of its V-Twin design allows the

engine to be located fairly close to the ground. But in a horizontal plane, a considerable amount of the Road King’s mass-particularlv the wheels, fork and fenders, all of which are heavy-is located far from the bike’s center of gravity. This increases the “polar moment,” which is the resistance of an object to rotational acceleration. When the mass of an object is distributed far from its axis of rotation, the object has a high polar moment of inertia. When the mass distribution is close to the axis of rotation, it has a low polar moment of inertia. When a motorcycle turns, it rotates about its center of gravity, and a high polar moment offers resistance to that turning. On top of that, Harley’s engineering criteria require its bikes to have superb stability, even if it has to come at the expense of agile handling; so the Road King’s steering geometry favors rock-steady straight-lining more than easy maneuvering.

Your buddy’s BMW, on the other hand, is around 150 pounds lighter than your Harley and has more of its mass positioned closer to its eg, as well as quicker steering geometry, a narrower front tire and a shorter wheelbase, with a eg that ’s at least as low. These and several other factors help it be more maneuverable than your Road King.

It would be practically impossible, then, to assign every bike a single measurement or grading number that would provide a meaningful rating of its maneuverability. Besides, we’re talking about a highly subjective quality here: When it comes to how motorcycles “feel,” one rider’s dream is often another rider’s nightmare.

Lashing out

I thought you provided an excellent expla nation of valve lash and adjustment in your response to Matt Stafford's "Got clear ance?" letter in the June issue, but I have a follow-up question: Why aren't mainte nance-free hydraulic tappets widely used in motorcycle engines? Is it a matter of mechanical complexity, added weight or simply a lack of available space?

ArrnaIKIO Cam acho Guadalajara, Mexico

Starting in 1948, overhead-valve Harley Davidsons were equipped with pushrods that incorporated integral hydraulic valve /ash adjusters. The company then switched to conventional hydraulic tappets in 1953 and has used them in all Big Twins to this

day, and Sportsters since their introduction in 1957. So if you take all that into consideration, along with the fact that the vast majority of the Harleys sold over the past several decades are still in use, you could legitimately say that hydraulic tappets are widely used in motorcycle engines. In addition, the engines in many Japanese cruisers have zero-maintenance hydraulic valve-lash adjusters, which operate on the same principle.

Hydraulic tappets such as those in a Harley use oil pressure from the engine ’s lubricating system to take up all the freeplay in the valve

train. A tappet consists of three principal components: the main body, which rides on the cam lobe; the internal body, which slips down inside the main body and con tacts another part of the valve train, usu ally the pushrod; and a spring-loaded check ball between the two bodies

CONTINUED

Without the assistance of oil pressure, the internal body of the tappet can move upand-down freely inside the main body; but when pressurized oil enters the tappet, it fills up the space between the inner and outer bodies, pushing the check ball closed and effectively turning the tappet into a solid, one-piece unit. The oil pressure is not sufficient to overcome valvespring pressure, which could cause a valve to hang open, but it is strong enough to push the inner body until it takes up all freeplay in the valve train. As the freeplay varies due to engine-temperature fluctuations and normal component wear, the tappet automatically compensates for the change.

Hydraulic tappets work well in engines that are comparatively low-revving; the aforementioned Harleys, for example, rarely exceed 7000 rpm, even in modified form. But if engine speeds increase much farther than that, hydraulic tappets have difficulty coping. They sometimes “pump down,’’ which means that the inertia of their rapid up-and-down movement causes the little check ball to unseat, thereby bleeding off some of the hydraulic pressure. When that occurs, the valve ’s lift and duration are both reduced.

Hydraulic tappets also can “pump up”> at higher rpm, a phenomenon brought on by the inertia of a moving valve. As the cam pushes the valve to the fully open position and the tappet begins its trip down the closing side of the cam lobe, the valve is moving so fast that it wants to continue opening. This causes a momentary reduction in the pressure exerted on the lifter by the valve spring, and that relaxation allows the engine’s lubrication system to pump a tiny bit of additional oil into the lifter. Once that happens a few times, the effective length of the lifter assembly grows enough to prevent the valve from fully closing, resulting in a loss of compression and, obviously, performance. So, either through pump-up or pump-down, engine performance is negatively affected, which is why high-revving, high-performance engines do not use hydraulic tappets.

FEEDBACK LOOP

In your "Like, totally gross" response to J.W. Salter in the October issue, you stated that dry weight is the weight of the motorcycle less fuel. You're wrong, my friend. Dry weight has always been unladen weight sans all fluids, battery and tools. It's beyond me who wants such a stupid number, but that's the way manufacturers play it. For in stance, the dry weight of the Honda GL1 800 is 790 pounds, but it weighs 898 fully fu eled (according to the calibrated scale of one magazine, and I don't remember which one). Fuel weight is 6.6 Ib./gallon, which comes to about 40 pounds. The rest is coolant, final-drive oil, engine/tranny oil, and brake and clutch fluid. Juan Cos El Paso, Texas

Your calculations may be valid ii you are dealing with a manufacturer's dry weight, but in my reply to Mr Salter I was referring to dry weight as measured by us-that is, on our calibrated scale, with a working battery and all fluids installed except fuel, plus, when applicable, a toolkit. As you indicate, any measurement that omits coolant, lubri cating oils, brake and clutch fluid, and the battery is worthless to a consumer~ be cause no one could ride the bike that way. Anyone who has ever run out of gas, how ever has operated a motorcycle-more than likely coasting, of course-with an empty fuel tank.

The last GL 1800 we weighed tipped the scales at 864 pounds without fuel, which is 72 pounds more than Honda's 792-pound claimed dry weight. The Wing has a large battery and carries a lot of coolant and lubricant, but not 72 pounds worth. So, the ra tionale behind the manufacturers' claimed dry weights remains one of the great un solved mysteries of the mechanical age.

By the way, the weight of gasoline varies between about 6.1 and 625 pounds per gallon, depending upon its temperature and the chemical composition of the specific fuel in question. With its 6. 6-gallon tank, the Gold Wing's fully fueled weight would be 904 to 905 pounds.

CONTINUED

Techtips

Installing like a classic a sparkplug no-brainer seems operation: Thread the old one out, thread a new one-or, after cleaning and regapping, the same used one-back in. Done deal.

But not so fast, Mr. Speedwrench; there’s a little more to this task than that. For starters, the body of the sparkplug is steel and the cylinder head into which you are threading it is aluminum. Dissimilar metals often gall when joined tightly together, and that can cause the softer threads (the ones in the head) to be damaged the next time the plug is removed. Putting a tiny dab of anti-seize compound on the plug’s threads before installation can eliminate that worry.

And did you torque the plug when installing it? Most people don’t, but that doesn’t mean you shouldn’t. If the plug has too little torque, it can work its way loose and jiggle around, potentially damaging the threads in the head. Even more important, an undertorqued plug might not be able to transfer sufficient heat of combustion to the cylinder head, escalating the plug’s operating temperature. This effectively makes it function like a hotter sparkplug than its intended heat range, which can lead to elevated combustion-chamber temperatures and severe engine damage.

Too much torque can have equally destructive consequences. Overtorquing a plug puts undue stress on its metal shell, which can distort its inner gas seals and even crack the insulator. This would also lead to higher combustion-chamber temperatures and eventual engine damage.

In an aluminum cylinder head, the recommended torque for a 14mm plug is 18.0 to 21.6 lb.-ft., and 10.8 to 14.5 lb.-ft. for a 12mm plug. A 10mm sparkler should be tightened from 7.2 to 8.7 lb.-ft., and an 8mm plug gets only between 5.8 and 7.2 lb.-ft. of torque. -Paul Dean

Some Japanese bikes with overheadcam engines use little hydraulic tappets atop the valve stems, right at the tip of each rocker arm, while some others employ stationary hydraulic tappet-like devices at the pivot end of finger-type cam followers. Both systems are self-adjusting and allow the engine to maintain zero valve lash, but they, too, are not suited for ultra-high-rpm applications. The small tappet atop the valve stem is subject to the same pump-up/pump-down shortcomings as a conventional tappet, and its rocker arm adds too much valvetrain weight to allow the rpm levels of 15,000 or more that are commonplace on today’s highperformance engines. And although the system that uses a stationary hydraulic pivot usually does not suffer pumpup/down symptoms, the cam follower adds just as much valvetrain weight as a rocker arm. This is why the cam lobes in highrevving engines push directly on the valve stems via a simple shim-under-bucket arrangement that is very light but requires occasional freeplay adjustment. □

Got a mechanical or technical problem with your beloved ride? Can't seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; 3) e-mail it to CWlDean@aoL corn; or 4) log onto www.cycleworld.com, click on the "Letters to the Editor" button and enter your question. Don't write a 10-page essay, but if you're looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Columns

ColumnsThe Remarkable Mr. Desmedt

December 2004 By David Edwards -

Columns

ColumnsA Minor Odyssey

December 2004 By Peter Egan -

TDC

TDCHeavy Duty

December 2004 By Kevin Cameron -

Departments

DepartmentsHotshots

December 2004 -

Roundup

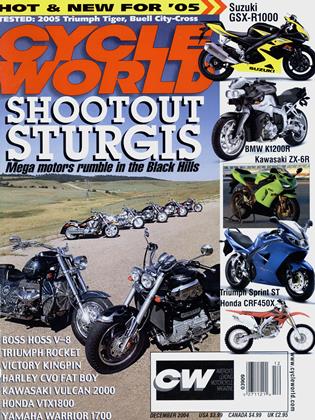

RoundupAll-New Suzuki Gsx-R1000!

December 2004 By Kevin Cameron -

Roundup

RoundupMoto-Street Suzuki

December 2004 By Mark Hoyer