The RPM Gap

TDC

Kevin Cameron

ARE YOU LYING AWAKE AT NIGHT, struggling with the question of why great big Formula One auto racing engines can rev higher than Superbikes?

It’s hard to sleep peacefully, knowing that the car people have figured out how to get their hulking 300cc cylinders to redline up at 17 or 18,000 rpm, when our four-cylinder 750 Superbike race engines (187cc cylinders) are struggling to make power down at a lowly 15,000. Usually reliable measures like counting sheep, turning the pillow over or drinking warm milk just aren’t working. Get up out of bed, pace the floor, ponder the problem in the warm darkness.

Bike engines were numero uno in technical sophistication back in the 1960s. Where have those salad days gone? Kennedy struggled with his Missile Gap in 1960; now we face The RPM Gap.

It’s possible that we’ll get answers soon. Shadowy sources of capital (reputedly from one of the exploding economies of the Far East) are funding an English company to design a competitive World Superbike racer. The engine designer, Al Meiling, has been quoted as saying that he believes the current liter Ducati Twin is nearer its design limits than are the current fourcylinder 750s, so the new engine will be a Four. Because the company, MCD, has done business in F-l before, it can be assumed that the new engine will have pneumatic valves.

Conventional metal valve springs limit the speed and vigor with which valves can be opened or closed. Slinky-like waves hammer back and forth in valve-spring coils that are hit too hard by the cam profile. The result is rapid fatigue failure and/or irregular valve action. Therefore, all F-l engine valves are now closed by gas springs, originated by Renault under their wonderful name, distribution pneumatique.

Kawasaki race team manager Rob Muzzy has referred to conventional springs as, “the one part that no longer belongs in the engine,” so he is clearly interested in pneumatic valves. The new Cagiva F4 750 Superbike, designed with Ferrari consultation, is aimed at 17,000 rpm, and can be expected to show some Formula One influence. A rumored French Superbike is said to incorporate pneumatic valves.

But there is uncertainty. What is the best way to reach very high revs and actually make useful power up there? One approach might be called the Cosworth/Ducati approach, and it cheerfully accepts very high piston speeds and the violent internal forces caused by piston acceleration. Engines and crankshafts bend and twist under the action of these forces, causing bearing and cylinder distortion that raises friction and taxes reliability. One track to high revs is just to live with these problems and cope as best you can. Ducati’s perennial crankcase cracking problems are a case in point, if you can stand the pun.

The other track is not yet officially admitted to exist, but evidence is strong that F-l engines are now running with absurdly shortened strokes that may be as little as one-third of their bores. Compare this with Superbike racing’s shortest-stroke engines, whose stroke is six-tenths of their bore. Big difference. Super-short strokes bring engine internal forces down to livable levels. And that leads to reduction of friction. With the new, shorter strokes come intentionally beefier moving parts and upsized bearings, better able to resist deformation. Another part of the package is beefed-up cases.

In bike racing, the undisputed king of piston speed is Ducati. This year’s 955 race engine peaks at something like 10,800 revs, which with its 66mm stroke gives almost 4700 feet per minute. These engines can safely rev to

12,000 if need be-up at 5000 piston feet per minute. That’s a lot of rattling

and banging in a small place. Ducati engineers wouldn’t push their design this hard if the competition wasn’t forcing them to it, and now their reliability is suffering. Parts are breaking. Maybe this is part of why Mr. Meiling thinks Twins have come as far as they can.

But with ultra-short stroke, that 300cc F-l auto-racing cylinder assumes dimensions of 104mm bore, 35mm stroke. Up at an astronomical 17,000 revs, such an engine would just be loafing along at a mere 3900 piston feet per minute. Stress levels would be down. Of course, special measures would be required to drive the valves so fast. And combustion-chamber shape would get worse-wider and thinner. But maybe not all that much worse. All that terrible thrashing up at 5000 piston feet per minute requires a lot of internal clearance to keep pistons, valves and heads from knocking one another silly. Down at a reduced stress level, those clearances might be tightened up a lot. Combustion chambers might not work all that badly then. Hmmm.

Just for fun, and purely as wild, irresponsible speculation, what would a 750cc Four look like if its bore was three times its stroke? Dimensions would be a silly-sounding 89mm bore, 30mm stroke. If we redlined this engine at a moderate 4000 piston feet per minute, that would be 20,000 rpm. Continuing with this back-of-the-envelope exercise, if we combine that

20.000 revs with reasonable numbers for cylinder filling and averaged combustion pressure, we come up with more than 200 horsepower.

Go ahead, knock down my house of cards with your reasonable objections. No company in its right mind would build a streetbike with a 30mm stroke. And a non-stock stroke won’t be acceptable to the race-sanctioning bodies. It might not work, anyway. But what a grand mental experiment! Only dogs will be able to hear the engines at peak revs, with the exhaust pulses coming at

40.000 per minute. And 200 horsepower-no wonder Meiling sees potential in the 750 Fours.

Ha ha, you’re not serious. Yes I am. There’s life left in the four-stroke principle yet. The serious question is, who’s going to go in and get it, so the rest of us can stop worrying about The RPM Gap and get some sleep. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontNotes From Seat 21a

August 1996 By David Edwards -

Leanings

LeaningsAre Dirtbikes Ugly Or Is It Just Me?

August 1996 By Peter Egan -

Letters

LettersLetters

August 1996 -

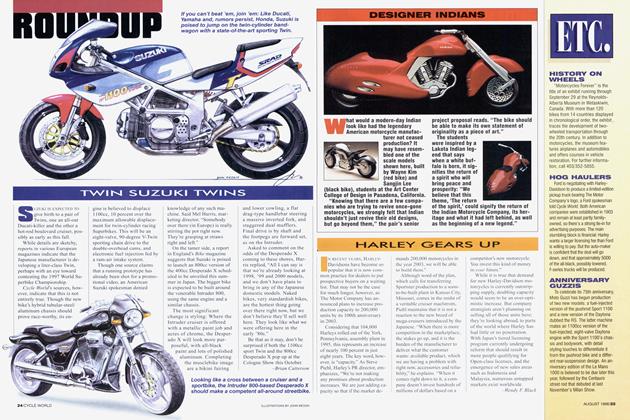

Roundup

RoundupTwin Suzuki Twins

August 1996 By Brian Catterson -

Roundup

RoundupDesigner Indians

August 1996 -

Roundup

RoundupHarley Gears Up

August 1996 By Wendy F. Black