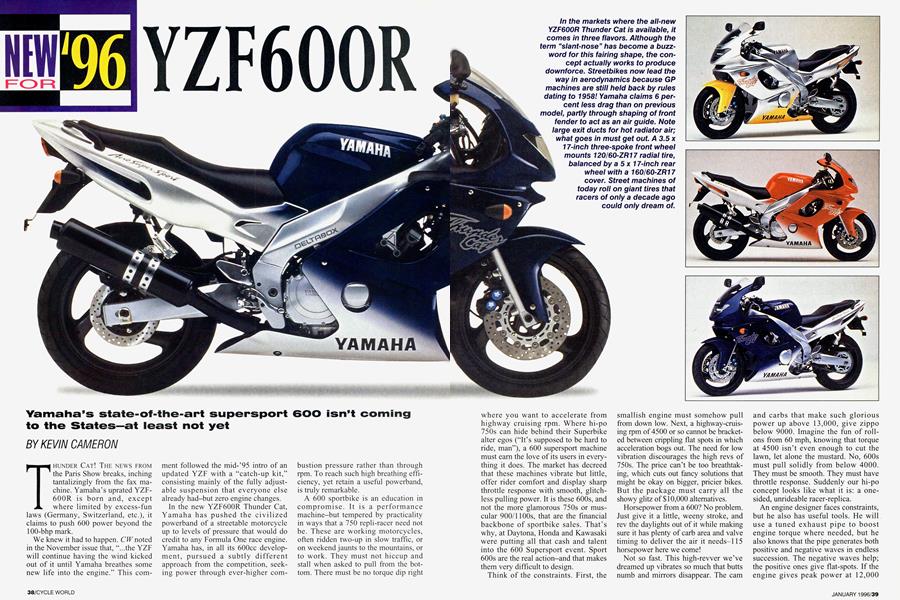

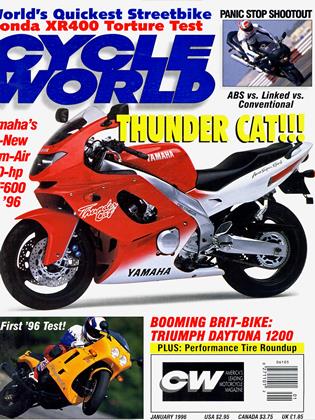

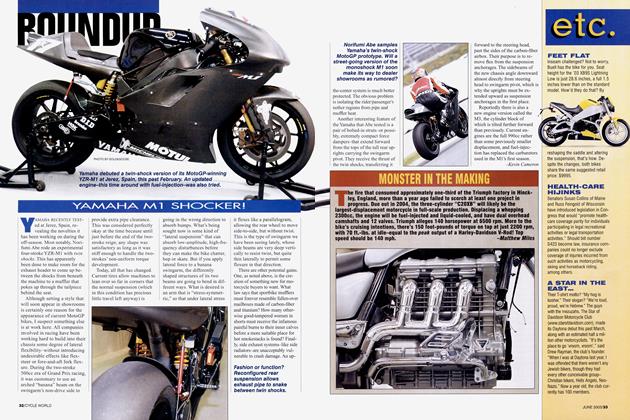

NEW FOR '96 YZF600R

Yamaha's state-of-the-art supersport 600 isn't coming to the States-at least not yet

KEVIN CAMERON

THUNDER CAT! THE NEWS FROM the Paris Show breaks, inching tantalizingly from the fax machine. Yamaha's uprated YZF600R is born and, except where limited by excess-fun laws (Germany, Switzerland, etc.), it claims to push 600 power beyond the 100-bhp mark.

We knew it had to happen. CWnoted in the November issue that, "...the YZF will continue having the wind kicked out of it until Yamaha breathes some new life into the engine." This com ment followed the mid-'95 intro of an updated YZF with a "catch-up kit," consisting mainly of the fully adjust able suspension that everyone else already had-but zero engine changes.

In the new YZF600R Thunder Cat, Yamaha has pushed the civilized powerband of a streetable motorcycle up to levels of pressure that would do credit to any Formula One race engine. Yamaha has, in all its 600cc develop ment, pursued a subtly different approach from the competition, seek ing power through ever-higher corn-

bustion pressure rather than through rpm. To reach such high breathing effi ciency, yet retain a useful powerband, is truly remarkable.

A 600 sportbike is an education in compromise. It is a performance machine-but tempered by practicality in ways that a 750 repli-racer need not be. These are working motorcycles, often ridden two-up in slow traffic, or on weekend jaunts to the mountains, or to work. They must not hiccup and stall when asked to pull from the bot tom. There must be no torque dip right where you want to accelerate from highway cruising rpm. Where hi-po 750s can hide behind their Superbike alter egos (“It’s supposed to be hard to ride, man”), a 600 supersport machine must earn the love of its users in everything it does. The market has decreed that these machines vibrate but little, offer rider comfort and display sharp throttle response with smooth, glitchless pulling power. It is these 600s, and not the more glamorous 750s or muscular 900/1100s, that are the financial backbone of sportbike sales. That’s why, at Daytona, Honda and Kawasaki were putting all that cash and talent into the 600 Supersport event. Sport 600s are the real action-and that makes them very difficult to design.

Think of the constraints. First, the

smallish engine must somehow pull from down low. Next, a highway-cruising rpm of 4500 or so cannot be bracketed between crippling flat spots in which acceleration bogs out. The need for low vibration discourages the high revs of 750s. The price can’t be too breathtaking, which cuts out fancy solutions that might be okay on bigger, pricier bikes. But the package must carry all the showy glitz of $10,000 alternatives.

Horsepower from a 600? No problem. Just give it a little, weeny stroke, and rev the daylights out of it while making sure it has plenty of carb area and valve timing to deliver the air it needs-115 horsepower here we come!

Not so fast. This high-revver we’ve dreamed up vibrates so much that butts numb and mirrors disappear. The cam

and carbs that make such glorious power up above 13,000, give zippo below 9000. Imagine the fun of rollons from 60 mph, knowing that torque at 4500 isn’t even enough to cut the lawn, let alone the mustard. No, 600s must pull solidly from below 4000. They must be smooth. They must have throttle response. Suddenly our hi-po concept looks like what it is: a onesided, unrideable racer-replica.

An engine designer faces constraints, but he also has useful tools. He will use a tuned exhaust pipe to boost engine torque where needed, but he also knows that the pipe generates both positive and negative waves in endless succession. The negative waves help; the positive ones give flat-spots. If the engine gives peak power at 12,000 rpm, there will be a pipe-generated torque dip at about 70 percent of that, or 8400. Below that, there’ll be another, smaller torque peak, with another dip below that at maybe 5000, and so on. The designer knows that he can get a lot of torque up high by combining valve overlap-the time during which both intake and exhaust valves are open together, just before the intake stroke-with strong pipe action. The open valves are the “window” through which pipe suction acts to start inflow from the carb even before the piston has begun its intake stroke. But that same open window will also, at lower revs, let through the positive pulses that kill torque.

Our hard-working designer therefore chooses a 4-into-2-into-l pipe. It sends twin signals back to the engine-one signal from the ends of the four head-

ers, another from where the secondaries join at the collector. By juggling lengths, it can be arranged such that at rpm where the primary signal goes positive (torque dip) the secondary signal off the collector junction is negative (torque peak). Thus, the two tend to buck each other out, leaving the powerband almost flat, where a 4-into-1 pipe would produce a deep hole. With a 4-21 pipe, the engine can now tolerate longer cam timing (more overlap, in this case) without making the engine fall into a well at 8000 or so.

Meanwhile, on the upstream side, intake tuning is applied, producing a train of positive (good, on the intake side) and negative (bad) pressure waves whose pumping effects further wrinkle up the torque curve. Most likely, our designer decides to use the primary intake wave to boost peak torque-this can yield a 20-percent gain in a limited rev range. Although it might be tempting to use intake tuning to smooth out troublesome dips lower down in the torque curve, it takes a lot of intake length to boost torque at lower revs, and there isn’t room for it under the tank. Can’t have stacks like a Mississippi steamboat.

What can iron out dips lower down the torque curve? Strange as it may seem, the airbox is a useful tool. In terms of physics, the airbox is a guitar, a big air-filled box with a hole in it. The air in the hole (or intake snorkel) is the vibrating mass, moving in and out like a piston, and the compressible volume of air in the box is the spring against which it bounces. The steady succession of suction pulses from the engine’s intakes is what sets this system into vibration (hear it honk as you hit resonant rpm). The game is to fix it so that pressure in the box is always positive just as a cylinder’s intake stroke is occurring. The box frequency is tuned by varying the length and diameter of the intake snorkel. To increase frequency, make the snorkel of larger diameter, or shorter, and vice versa.

Back when the intake snorkel lived under the seat/tank junction, its radiated honking was a big problem. But today, when ram airboxes, with their forwardfacing intakes, are so fashionable, the box intake can radiate its noise forward-directly away from exhaust roar-thereby reducing the peak detected by the EPA’s sound meters. And so, box resonance is no longer a nasty noise source, to be suppressed with foam and baffles. Now it’s a torqueboosting tool, and a very good one.

The original FZR600 was a stroked 400, so it ended up with the unfashionable bore and stroke of 59.0 x 54.8mm, numbers that nearly equal each other. This long stroke limits rpm, and the smallish bore limits valve area. But lo! Yamaha made a success of it in 1989, against Honda’s CBR600 and Suzuki’s Katana 600, by stuffing so much air into it that it outpowered its rivals on sheer cylinder pressure, with power peak at a mere 10,000 rpm. Why? First, the un-cool bore/stroke dimensions gave it a small, fast-burning combustion chamber that could tolerate high compression without knock. Although the data sheet claimed only 12:1, real compression ranged from 12.8 upwards beyond 13:1. All that compression helped torque a lot, at all speeds, which is just where 600s need it. Honda replied with the F2, with its short stroke of 45.2mm and large, 65mm bore. Honda took some airpumping ability away from lower revs, adding top-end, resulting in race-winning power and acceleration.

Yamaha came back with the YZF600, but anyone expecting a race-based design was disappointed; new bore and stroke were still conservative at 62.0 x 49.6mm-a 600 stroke longer than in any 750! Why? Yamaha’s engineers were onto a good thing. By making power with improved air-pumping and combustion, they didn’t have to rev the engine very high, so it in turn didn’t need the larger valves and carburetors that kill bottom power. Getting an engine to breathe well at all rpm means running short valve timing, but with high lift and very rapid opening and closing. This, by crowding the whole intake event into the suction stroke, makes it unnecessary to let much of the valve timing “overhang” past bottom center, where it would eat into bottom power. It also puts severe demands upon valve action. Even though the bore of the YZF was bigger, Yamaha didn’t adopt it to make room for bigger valves; that might have hurt bottom power. Instead, everything in the valvetrain was lightened so the valves could be opened and closed faster, allowing intake to occur in less time. This maintained torque at higher rpm, but boosted it at lower revs, where the exhaust pipe was “off the air.”

The result has been truly amazing levels of cylinder-filling-levels that many pure racing engines have never reached. All this has resulted from necessity; starting with an accidental bore and stroke, then working under the severe 600 market constraints. Now the data sheet for Thunder Cat proclaims 100 horsepower at 1 1,500 rpm, with 48 foot-pounds of torque at 9500, both new highs for this class.

Where is it coming from? First new feature is a ram airbox with two subresonators and a forward-facing intake. Here, it’s not so much the pressure from ram effect-a puny 3 percent at a naughty 150 mph-as it is: 1) complete segregation of engine intakes away from hot radiator air; and 2) a better layout for employing airbox resonance to boost engine torque. The former 34mm carbs are replaced with water-

heated Keihin CVKD36s. What? This technology comes to us from aircraft, by way of snowmobiles. The colder the air an engine breathes, the more likely is the formation of carburetor ice in the venturis, where low pressure and fuel evaporation drop the temperature far below ambient. Carburetor heat may also help to evaporate some of today’s less-volatile gasolines, contributing to improved throttle response (and even to that mundane variable, fuel mileage).

The list continues with apparently unrelated details. Lighter, forged pistons replace the former cast units, and the alternator’s flywheel mass has been cut 10 percent. Engine acceleration from small throttle openings is assisted by a throttle position sensor (TPS), informing the ignition box that it may kick in some extra advance at such moments. Midrange-boosting crossover piping is employed on the exhaust headers.

All of these details tell a tale: Some bottom performance has been relocated “upstairs,” probably by a cam-timing change. Its loss is being made up in this variety of ways. We’ll have to await the full road test (if we ever get this model) to see how well Yamaha has fitted a nice, woolly sheep’s powerband over this long-fanged Cat engine. We predict that where you’d expect unacceptable dips in the torque curve, there remains only a pimple here and there, to show where all the hard work was done.

Now the big question: When do we get these lovely kitties here in the U.S.? Answer: Not now. T-Cats are headed to Europe immediately, but when Yamaha USA officials here are quizzed about it, they reply vaguely that new models are “tied up in EPA testing.” Maybe, but we suspect they are so dazzled by forecasts of success for the new Royal Star mega-cruiser, they have forgotten their business.

Too bad. □