SERVICE

Paul Dean

Watts up?

A few months ago, my dad bought me an aftermarket headlamp for my 1989 Yamaha Radian 600. This new light has a 90/100-watt rating, almost double that of the stock, 55/60-watt bulb. He earlier had put one of these bulbs in his '93 Intruder and had no problems, and the shop he bought it from said that I wouldn't, either.

That was right before I got stranded with a dead battery. I charged it but later found that it had a dead .cell. My experience as an auto mechanic tells me that the dead cell is unrelated to the added demands of an ultra-powerful headlight, but I'd like another opinion. A voltmeter across the battery shows about 1474 volts w'ith the bike running at the specified rpm. Is there a test I can do to be sure the battery is getting what it needs? I’d rather not participate in another “experiment” with no kickstarter and a battery so dead I can't even bump-start my bike. Joe Rogers

Kansas City, Kansas

Your suspicions are correct: Installing a high-powered headlight did not cause one of your battery s cells to go dead. Cell failure occurs when a battery spends a long period in a state of discharge, is charged at too high of a

rate, or is not adequately isolated from engine and road vibration: and sooner or later, cell failure will occur simply through old age.

Obviously, when a vehicle ’s electrical equipment demands more current

than its charging system can replenish, the battery will continue to discharge until the engine either begins running poorly or shuts down altogether. But if the battery is recharged as soon as possible, it should suffer no permanent damage.

Under some circumstances, though, your Radian 's alternator might have trouble keeping the battery charged. Even with the stock headlight, the alternator does not begin charging the battery until around 2000 rpm. If you add the extra draw (nearly 3 more amperes) of your "flame-thrower” headlight, the battery probably isn 7 getting any significant charge until somewhere between 2500 and 3000 rpm. So, if you toodle around town at low revs and activate the brake light frequently, the battery could lose its charge fairly quickly.

Your voltage check indicates that the charging system is in good working order at "the specified rpm,” but you didn 7 state what that rpm was or who specified it; / can only assume that it was 5000 rpm, Kawasaki’s recommended engine speed for checking the alternator’s output.

For your purposes, though, what ’s important is the rpm at which the battery first starts receiving a charge. To check this, you 'll need an ammeter that has at least a 10-amp capacity. With the engine running at normal idle, disconnect the ground cable from the negative terminal of the battery. Clip the positive lead of the meter to the negative terminal of the battery, and connect the negative lead of the meter to the ground cable. You 'll then see that at idle, the ammeter reading is in minus territory, and that as you slowly increase rpm, the needle gradually moves to the positive side of the scale. So, with the headlight on low beam, note the rpm at which the ammeter begins giving a positive reading. You then will know that any time the engine is running below that rpm, the battery is discharging, and that if you spend too much time in that rpm range, the battery is likely to go dead.

Pinch me gently

While remounting the front wheel on my `85 BMW K100RT, I acciden tally overtorqued the front-axle pinch bolts to 20 foot-pounds instead of the recommended 10. After realizing my error, I backed out the pinch bolts and retorqued them to the proper value,

then marked each bolt with a dab of paint. Should I forget the whole affair and do nothing more, or have the bolt holes tapped to the next larger size, or have the bolt holes drilled through and use a bolt-and-nut configuration?

Dennis J. Bogusky Temperance, Michigan

None of the above. Instead, just replace the pinch bolts.

Unless there is more that you aren 7 telling me, your overexuberance with a torque wrench should only have stretched the pinch bolts, possibly just enough to effect a marginal reduction in their tensile strength. I seriously doubt that the 10-foot-pound excess of torque was sufficient to damage the threads in the fork sliders.

I assume that you marked the bolts with paint after the overtorquing incident so you could easily tell if they were loosening during subsequent use. Good idea, but not necessary. If the bolts were to relax their pinch on the axle, they would do so not by rotating but by elongating very slightly due to their loss of tensile strength.

O, no, Mr. Bill

After 17 years between my last two bikes, first a Suzuki GS850G and then a GSI 100G, I now find myself with a Honda CB900F that has chain drive. Seems I got to shaft-drive bikes about the time O-ring chains came along, meaning that I have no experience with these kinds of chains. So, one simple question: 1) Does an Oring chain require chain lube? If not, 2) will chain lube help more than make a mess? Bill Hiller

Port Angeles, Washington

One simple answer, Bill: a) No; and b) no.

O-ring chains do not require the same kind of lubrication as conventional chains. The critical internal friction areas are packed with lubricant during manufacture, and the Orings are there to keep the lube in and the dirt out. But in practice, O-ring chains enjoy a longer life if they're occasionally sprayed with a waterdispersing lubricant such as WD-40. Lubes of this type prevent the chain from rusting after it makes contact with water; and because they aren 't sticky like conventional chain lubes, they don 7 attract dirt and grit that can grind the O-rings to pieces. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

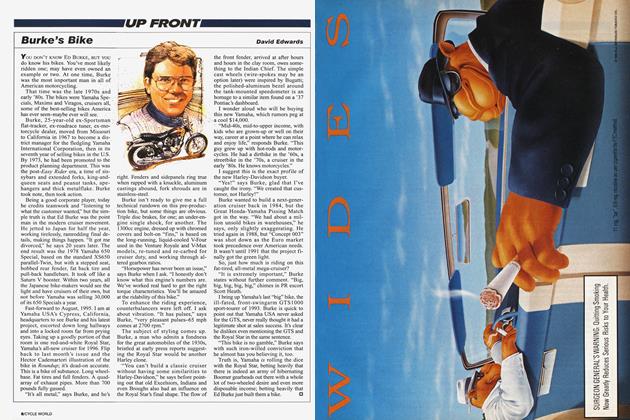

Up FrontBurke's Bike

November 1995 By David Edwards -

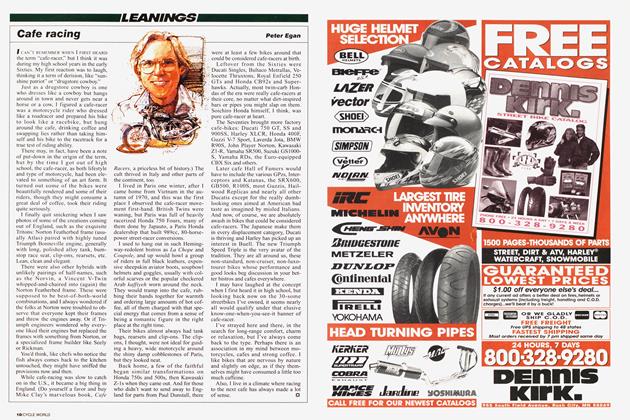

Leanings

LeaningsCafe Racing

November 1995 By Peter Egan -

TDC

TDCExtremes

November 1995 By Kevin Cameron -

Letters

LettersLetters

November 1995 -

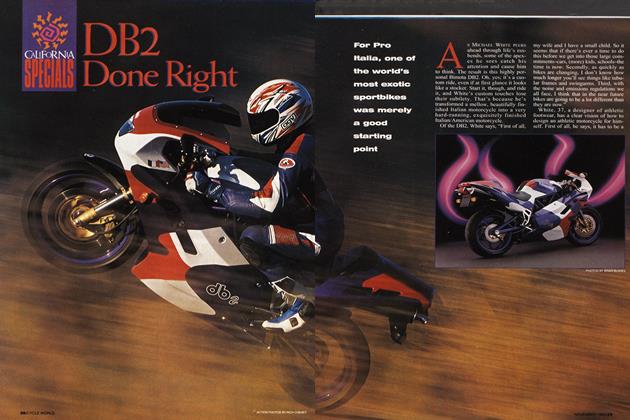

Special Section

Special SectionCalifornia Specials

November 1995 By Jon F. Thompson -

California Specials

California SpecialsDb2 Done Right

November 1995 By Jon F. Thompson