FRENTUBO KEVLAR BRAKE LINES

Beyond braided-steel

ONE OF THE FACTORS THAT lessens a rider’s confidence in his brakes is a soft, mushy-feeling brake lever.

Movement of the brake lever activates a hydraulic piston in the bike’s master cylinder to pressurize brake fluid that ultimately pushes the brake pads against the rotors. The harder the rider squeezes the lever, the higher the pressure in the lines that connect the master cylinder to the front calipers. Industry testing indicates two important things: First, the highest line pressures generated by a master cylinder with a 5/8-inch piston and activated by a gorilla-like squeeze in a full-emergency situation likely will not exceed 3000 psi, with line pressure during most vigorous stops not exceeding 2000 psi. Second, most calipers begin flexing at about 1000 psi. Rubber brake lines typically begin expanding under pressure at only 250 psi. In a properly set-up system-one that uses good quality calipers, is not overheated and has no air in the system-it is this brake-line expansion that is responsible for mushy lever feel. That’s why discerning riders upgrade the brake lines on their bikes.

Until now, the upgrade of choice has been to braided-steel lines, which typically don’t begin expanding under pressure until about 6300 psi. But if some is good, more is better, and that’s where Frentubo Kevlar brake lines ($154 from Fast By Ferracci, 1641 Easton Rd., Willow Grove, PA 19090; 215/657-1276) come into the picture. Kevlar lines are lighter than steel ones, and, according to Ferracci, they resist expansion at pressures of up to 8000 psi.

Skeptical, we obtained a set and installed it on a 1990 Ducati 851 with a notoriously spongy lever. The lines work as advertised, firming up lever feel and greatly improving the rider’s control over the braking process.

Clearly, steel lines would have had the same effect on the lever feel of our

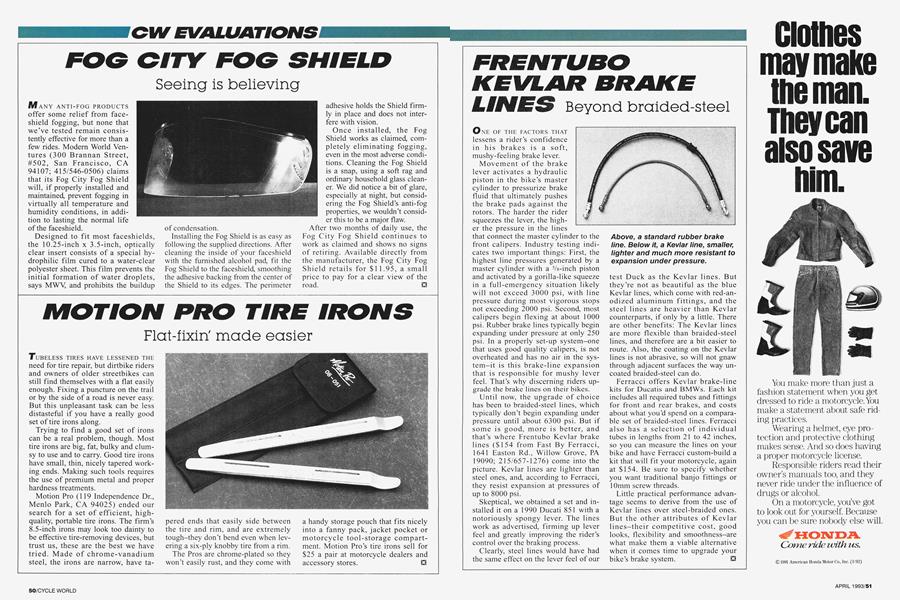

test Duck as the Kevlar lines. But they’re not as beautiful as the blue Kevlar lines, which come with red-anodized aluminum fittings, and the steel lines are heavier than Kevlar counterparts, if only by a little. There are other benefits: The Kevlar lines are more flexible than braided-steel lines, and therefore are a bit easier to route. Also, the coating on the Kevlar lines is not abrasive, so will not gnaw through adjacent surfaces the way uncoated braided-steel can do.

Ferracci offers Kevlar brake-line kits for Ducatis and BMWs. Each kit includes all required tubes and fittings for front and rear brakes, and costs about what you’d spend on a comparable set of braided-steel lines. Ferracci also has a selection of individual tubes in lengths from 21 to 42 inches, so you can measure the lines on your bike and have Ferracci custom-build a kit that will fit your motorcycle, again at $154. Be sure to specify whether you want traditional banjo fittings or 10mm screw threads.

Little practical performance advantage seems to derive from the use of Kevlar lines over steel-braided ones. But the other attributes of Kevlar lines-their competitive cost, good looks, flexibility and smoothness-are what make them a viable alternative when it comes time to upgrade your bike’s brake system.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontGreen Machines

April 1993 By David Edwards -

Leanings

LeaningsYou Ain't Goin' Nowhere

April 1993 By Peter Egan -

TDC

TDCSpring To Action

April 1993 By Kevin Cameron -

Letters

LettersLetters

April 1993 -

Roundup

RoundupYamaha To Go Standard?

April 1993 By Jon F. Thompson -

Roundup

RoundupBimota Presses On With Gp Streetbike

April 1993 By Alan Cathcart