TDC

The art of downsizing

Kevin Cameron

MUCH OF THE POWER GAIN ACHIEVED in Superbike engines in the past five years has come from friction reduction. Engines operating at moderate rpm levels have mechanical efficiency near 85 percent, which is to say that, of the power produced at the piston crown, only 15 percent is consumed in mechanical friction. As revs are pushed higher, friction takes more as the engine structure flexes, bearings and cylinder bores vibrate into and out of alignment, and the shearing of oil films in crank journals, and between pistons and cylinders, takes place at ever-higher speeds. This “friction tax” may rise so high that gains are eaten by losses.

The response to this is to shrink all moving parts. Pistons become lighter, so con-rods don’t have to be as hefty, and therefore rod bearings can be downsized along with the loads-a synergistic process. With lighter parts, vibratory loads decrease, requiring less engine and chassis structure weight, and so on.

How far can it go? If piston crowns are thinned too much, they will melt, but even so, pistons have shrunk to mere discs with mini-skirts. Often, only two piston rings remain-the top one to seal gas pressure, the bottom one to keep oil from reaching the combustion chambers. Wristpin bosses have become vestigial prongs, hanging from the underside of the crown. Wristpins have become very short, made of super-duty steels, surface-hardened to prevent their picking up aluminum from the heavy friction in the bosses.

Con-rods are pared-down in a cooperative process in which finite-element computer analysis proposes a design, and real-world testing confirms or denies its correctness. Rods have become tiny, and the materials in production parts are far stronger than the mild steel of a few years ago.

As a plain bearing is downsized, its load increases in terms of pounds per square inch of projected bearing area. This pushes the journal closer and closer to the bearing surface, and the oil film is squeezed perilously thinner. To keep the micro-roughness on the parts from making metal-to-metal contact, surface finishes must be improved, requiring new manufacturing and gauging processes.

As with any design trend, the big gains come at the beginning, and are harder to find as time passes. But this trend toward friction reduction doesn’t exist in a vacuum; it is related to, and driven by, the need to rev engines higher. However, as rpm increases, vibratory forces increase as the square of the rpm: Double the rpm, get four times the shaking and pounding. The only escape from this is to reduce vibratory forces by making the parts lighter. With some production 750 engines redlined at 13,000, Superbike engines are reaching for 15,000 revs and above. Can metal parts continue to shrink enough to permit this?

The answer is yes, but something better will be needed soon to support further substantial gains. Thinner, lighter metal pistons may be kept from melting by oil-jet cooling their undersides, at some cost in oil pumping and complexity. Motorcycle valves have still not reached the attenuated proportions of those in Formula One auto engines-the “dime-on-atoothpick” look. There is more to come, but not a lot. And then?

History shows that engineering attacks its problems with a given set of solutions until the gains stop coming. Then someone demonstrates a fresh solution, and it is quickly refined to death until it, in turn, is exhausted. So it goes.

Current engine materials-metalsare a jumble of defective crystals, joined haphazardly at their boundaries. Their strengths are only a small fraction of what they would be if they con-

sisted of single, perfect crystals. Composite materials derive their extraordinary strength from fibers which are far closer to perfect crystals. As designer John Britten has said, once you’ve worked with carbon-fiber composites, you lose some of your trust in metals.

Yet metals remain attractive because, instead of failing suddenly from fractures that move at the speed of sound, they yield slowly, consuming a lot of energy in the process, greatly delaying or preventing the failure process. That property of metals has allowed us humans to make large design errors and still have workable parts.

Composites currently lack this forgiving property. The silicon carbide that suggests pistons or valves half the weight of metal ones is a ceramic, a mineral, that breaks like glass. The carbon fiber that suggests vanishingly small and light connecting rods hardly elongates at all under stress-before snapping.

The problems of non-metallic materials are formidable, but their potential value is such that their successful development and application are assured.

Another technology currently overdue for the most sophisticated of motorcycles is the French innovation, DP, or distribution pneumatique. Each increase in rpm capability brings with it a need for heavier valve springs, heftier tappets and general strengthening all down the cam-drive train. This is the very opposite of the progression towards lighter parts and friction reduction. To escape this, designers at Renault eliminated the valve springs, replacing them with gas pressure. This pressure acts on a small piston, attached to the valve stem, sealing against a surrounding cylindrical bore. The leakage that occurs is made good from a small gas bottle and regulator. When more “valve-spring pressure” is required, you simply dial up the pressure on the regulator. In calculating valvetrain reciprocating weight, one-third of the weight of the spring is figured in. This is a lot when the spring is steel. It’s very small when the spring is a gas.

Perhaps you’ve heard the story about the patent office chief who resigned in the 1890s, saying that nothing more could possibly be invented. I’d say his career move was premature. □

View Full Issue

View Full Issue

More From This Issue

-

Columns

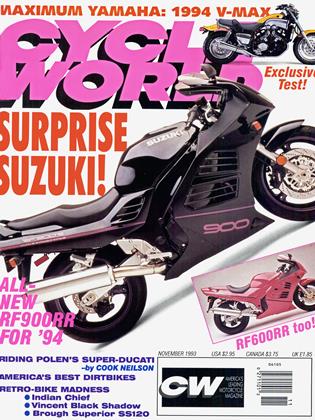

ColumnsUp Front

November 1993 By David Edwards -

Columns

ColumnsLeanings

November 1993 By Peter Egan -

Letters

LettersLetters

November 1993 -

Roundup

RoundupTriumph To Launch Two New Triples

November 1993 By Roland Brown -

Roundup

RoundupThe Austrians Advance

November 1993 By Alan Cathcart -

Roundup

RoundupMany Valves, Much Horsepower

November 1993 By David Booth