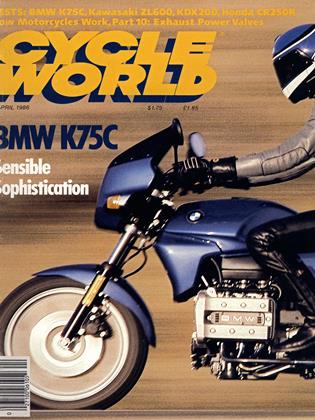

HOW motorcycles W.O.R.K 10

EXHAUST POWER VALVES

STEVE ANDERSON

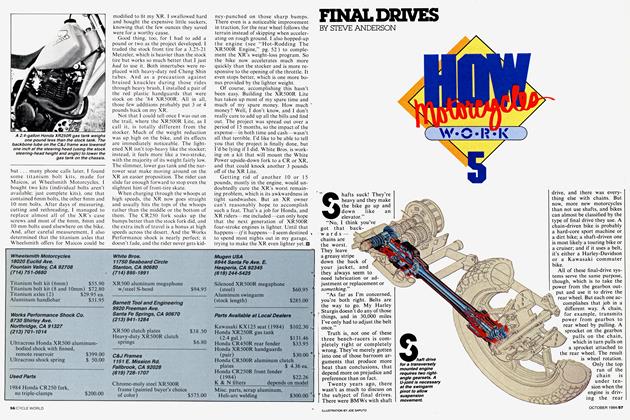

TWO-STROKES USED TO be simple. A cylinder, a piston and a crankshaft were pretty much all that was needed, with just enough structure to hold everything together. And the cylinder itself was just, well, a cylinder, with cooling fins and four ports: one for exhaust, one for intake, and two transfer ports, one on each side. The piston controlled the opening and closing of the ports, and only the piston and crank actually had to move.

Simple. But that's the past. While a few engines'~ adhering to these basics / can still be found in / mopeds or weed-cut ters, most motorcycle two-strokes have become ever-more com plex-first by the sheer \ multiplicity of ports, \ second by the use of `~ reed or disc valves to con trol intake-port timing, third by the addition of liq uid-cooling, and, most re cently, by the introduction of a bewildering array of ex haust-control mechanisms usually referred to as `power valves." Each manufacturer has its own system labeled with suitably sexy initials or acronyms (YPVS, ATAC, RAVE, etc.). And all the sys tems make use of links, cams, centrifugal governors or elec tronic controls to move a but terfly, poppet, guillotine or drum valve that somehow varies the geometry of the ex haust system or port. all with the intent of making more power over a broader range of engine speeds.

Admirable in intent, these systems have added an almost unimaginable level of com plexity to two-stroke engines. Take Honda's 1986 CR25OR. Its HPP (Honda Power Port) system adds at least 42 sepa rate components to the en gine, and Honda recom mends the removal of carbon deposits from the exhaustport valves every two-and-ahalf hours of running time.

But despite all the parts they contain and the vast dif ferences in their execution, these exhaust-control systems are simple in concept. They do one of two things: As en gine speed varies, an exhaust control system either changes the timing of the exhaust port's opening and closing, or changes the tuning of the ex haust pipe. With this enginespeed-sensitive variability, exhaust-control systems can have tremendous effects on power output, effects that spring straight from the fun damentals of two-stroke en gine operation. (For a review of basic two-stroke principles, see "How Motorcycles Work, Part 2: The Two Stroke En gine," April, 1984, issue).

Imagine a two-stroke pis ton at the top of its stroke, with the pressure of combus tion pushing it downward.

The piston descends as the hot exhaust gases expand, translating their heat and pressure into power-until the exhaust port is uncovered. At that point, any remaining pressure is simply dumped out the pipe. Obviously, then, delaying the opening of the exhaust port (by having its top edge lower) translates into more efficient use of the energy freed by combustion, which should increase power.

But even though it should, other factors can keep it from actually doing so. While the piston is descending, it must expel most of the burned combustion gases from the cylinder before the transfer ports are uncovered. This pe riod between exhaust opening and the first opening of the transfer ports is known as the blow-down period, and it is responsible for ensuring that the pressure in the cylinder has fallen below the pressure in the crankcase before the transfer ports open. That way, as the piston uncovers the transfers, fresh mixture from the crankcase will be forced up into the cylinder by the differential in pressure, push gng the remaining exhaust gases out the exhaust port

while filling the cylinder.

Maintaining a reasonable blow-down period dictates how low the top of the ex haust port can be; delay ex haust opening too long, and the pressure in the cylinder will be high when the transfer ports open, and cylinder-fill ing efficiency will decrease, along with power. But early exhaust opening also means late exhaust closing, which can give the fresh mixture ar riving in the cylinder too much time to escape out the open exhaust port.

So there are several trade offs at work here. For expan

sion efficiency. the exhaust port should open late; for cyl inder-filling efficiency. it should open early; and for ef ficiency in retaining the fresh mixture in the cylinder, the exhaust should close early (which means also opening late).

There's no single answer to that trade-off; the optimum exhaust-port timing will de pend on engine speed. High engine speeds mean moving air and exhaust gases through the engine more quickly, and that means larger port areas and earlier openings than would be optimum for an en-

gine that needs to peak at lower rpm. A simple twostroke can't have ports that are best for both low and high speeds.

That's where exhaust power valves come into play. With varying degrees of effec tiveness, they allow the roof of the exhaust port to be raised or lowered. The port can have low-speed timings for improved low-rpm perfor mance, and high-speed timings for better higher-rpm performance. Yamaha's YPVS (Yamaha

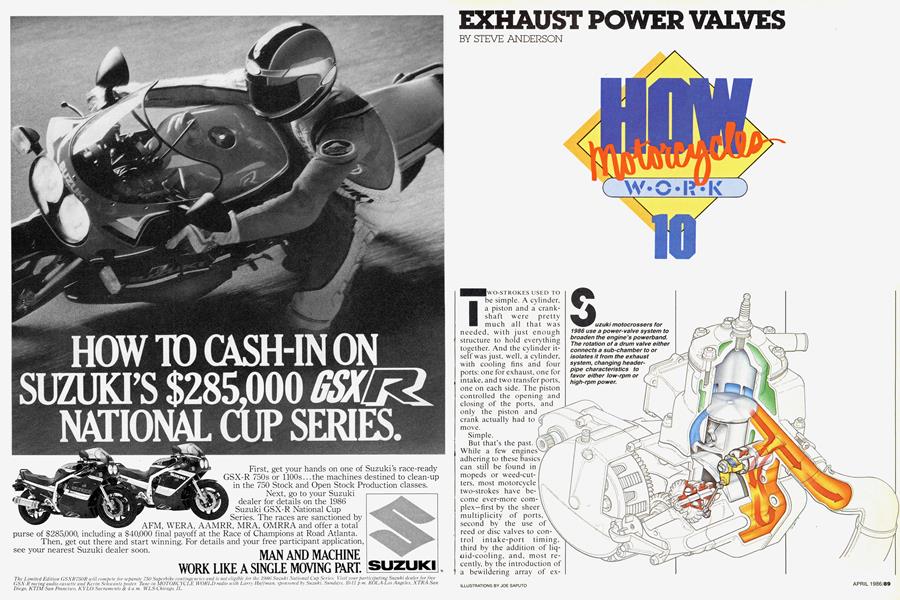

Power Valve System) broke the ground for the application of exhaust-control devices on motorcycles (Fig. 1). YPVS is a cylindrical drum that passes horizontally through the top part of the exhaust port. The drum is cut away so that it doesn't protrude into the port in its full-open position, but it effectively lowers the top edge of the port when rotated. A slight drawback of this de sign is that there is a bit of cyl inder-pressure leakage simply because the drum can't mate up closely to the piston rings; but overall, YPVS widens the powerband while not being terribly sensitive to carbon build-up.

Yamaha also broke ground with the mechanisms that control the power valve. There are two, their use de pendent on the complexity of the particular motorcycle's electrical system. For motocrossers, which have no battery, a centrifugal flyball governor controls power-valve movement through a system of levers and links (Fig. 2). For streetbikes and works roadracers, Yamaha uses an electric servo motor to move the valve, pushing and pulling it with cables. The servo motor itself is con trolled by signals from the ig nition black box.

Other manufacturers soon followed Yamaha's lead. Rotax employed a sliding guillotine valve in its RAVE (Rotax Automatically Vari able Exhaust) system (Fig. 3). RAVE varies exhaust-port height just as Yamaha's YPVS does, but the guillotine can snuggle up closer to the pis ton in its fully closed position, allowing less exhaust-pres sure leakage. What's more, Rotax controls the valve in a unique and simple manner with a piston that moves in accordance with changes in the average exhaust pressure; no monkey-motion linkages in this engine.

Honda's new HPP system may be the last word in vary ing exhaust port timing (Fig. 4). It uses two elaborately contoured guillotines that slide in from the sides to block the top one-third of the ex haust port. They duplicate the curve of the cylinder wall so accurately that they seem almost an extension of it when closed; the guillotines are only thousandths of an inch inset from the cylinder, and offer little area for ex~ haust leakage. And the per formance of the new HPP equipped CR25OR is brilliant; it has an excellent powerband with very strong peak power. The sacrifice, though, is in maintainability. The precision pieces of the HPP system are susceptible to jamming with exhaust-depos ited carbon, and the frequent cleaning required will limit HPP (at least in its current form) to use on racing bikes.

Honda's ATAC system varies exhaust-system tuning instead of port timing. This particular version uses a butterfly valve to control exhaust flow into a sub-chamber, but other versions use a poppet valve. In the smaller drawings, the action of the flyball governor is shown; the governor controls valve opening according to engine speed.

Before Honda had HPP, it had ATAC (Automatic Torque Amplification Sys tem), which is still uses on some of its two-strok~s. ATAC falls into that second class of exhaust-control de

vices-those which vary ex haust-pipe tuning rather than port timing, a simpler solu tion that can be very effective.

Here's why: If you know about the exhaust pipe's func tion on a two-stroke, you also know that pressure-wave tun ing inside the pipe is used to help scavenge exhaust gases from the cylinder. Initially, there's a suction created at the exhaust port as the ex haust gases pass through the divergent, front section of the pipe. This helps clear the cyl inder and pull fresh mixture up through the transfer ports. Later, as the exhaust is forced

to re-converge by the rear cone of the pipe, a positive pressure-wave is reflected back to the exhaust port. All these effects are taking place at the speed of sound; and if the pipe lengths and angles are right, and if the engine is turning at the right rpm, the positive pressure-wave reaches the exhaust port just in time to take fresh mixture that had escaped into the ex haust pipe and shove it back into the cylinder.

Unfortunately, a fixed length exhaust pipe will only be effective over a limited rpm range; at other engine

speeds, the pressure waves rattling about the exhaust will arrive at the cylinder at pre cisely the wrong time, actu ally reducing power. Go-kart tuners were among the first to find a partial solution to this problem: a hole in the ex haust header pipe that could be open and shut by a valve, thus changing the pipe's tun ing. If the kart driver let en gine rpm fall below the nor mal powerband, opening the valve would boost power below that range, down where the engine was normally "off the pipe."

Honda's ATAC is simply a refinement of that idea, with the hole now connected to a separate closed chamber (Fig. 5) with a valve between the two. By opening or closing the valve, slightly different pipe-tuning effects can be achieved. The result is an ex haust pipe with two personal ities. With the ATAC valve closed, the header-pipe's vol ume is smaller, which is better for high-rpm power; with the valve open. the larger volume is more suited for lower-rpm torque.

Suzuki's SAEC system, like Honda's ATAC, varies exhaust-system geometry. Suzuki uses a drum valve (with a slot through its center) to control exhaust access to a sub-chamber cast integrally with the cylinder and the head.

Actual construction details of ATAC-type systems vary widely. Honda uses both but terfly and poppet valves in different incarnations of ATAC: and Suzuki, with its quite-similar SAEC (Suzuki Automatic Exhaust Control) system. uses a drum valve (Fig.6). Valve opening can be controlled either by a centrif ugal governor, or by an elec tric solenoid.

Then there's the design that incorporates both pipe and port variability in a single system. Kawasaki's KIPS (Kawasaki Integrated Power valve System. Fig. 7) has three exhaust ports: one central port, with two small eyebrow subports on either side that open at the same time as the main port. Little drum-type valves close off the small ports. but with a difference: One port is simply closed, but as the other is shut, an ATAC like resonance chamber is opened to the exhaust. The effect is to slow exhaust flow out of the cylinder when the valves are shut by reducing exhaust-port area, and to change header-pipe charac teristics by adding the subchamber. As with the other systems. the end result with KIPS is a wide powerband with good peak power, as evi denced by the strong-running KX125. which has yet to be bested in 125-class moto cross competition.

So while exhaust-control systems have moved twostrokes away from their basic simplicity, pushing them far ther and farther toward fourstroke levels of complexity, they are also pushing them closer toward achieving a four-stroke's broad power range. Kel Carruthers. Kenny Roberts' tuner, commented a few years ago that two-strokes soon could have more valves than any four-stroke. He may yet be proven right. If and when he is. two-strokes may not just make more power than four-strokes: they may make better-qua/ii'r power as well.

View Full Issue

View Full Issue

More From This Issue

-

Editorial

EditorialBack To Square One?

April 1986 By Paul Dean -

At Large

At LargeThe Ultimate Vee

April 1986 By Steven L. Thompson -

Letters

LettersLetters

April 1986 -

Roundup

RoundupLatest Ninja Offspring

April 1986 By Koichi Hirose -

Roundup

RoundupThe Black Queen

April 1986 By Alan Cathcart -

Features

FeaturesHigh In the Thin, Cold Air

April 1986 By Koji Hiroe