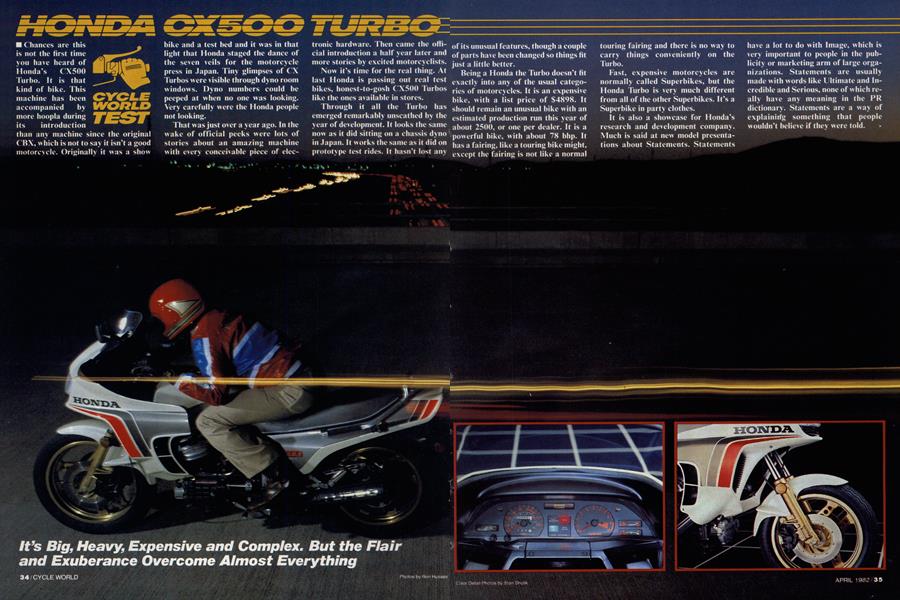

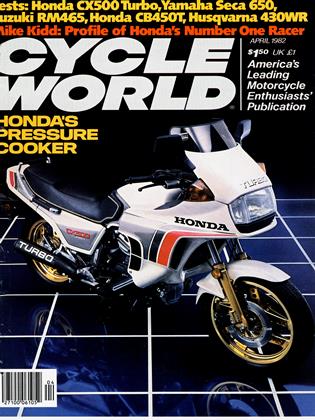

HONDA CX500 TURBO

CYCLE WORLD TEST

It's Big, Heavy, Expensive and Complex. But the Flair and Exuberance Overcome Almost Everything

Chances are this is not the first time you have heard of Honda's CX500 Turho. It is that kind of bike. This machine has been accompanied by more hoopla during its introduction than any machine since the original CBX, which is not to say it isn't a good motorcycle. Originally it was a show

bike and a test bed and it was in that light that Honda staged the dance of the seven veils for the motorcycle press in Japan. Tiny glimpses of CX Turbos were visible through dyno room windows. Dyno numbers could be peeped at when no one was looking. Very carefully were the Honda people not looking.

That was just over a year ago. In the wake of official peeks were lots of stories about an ama/ing machine with every conceivable piece of elec-

tronic hardware. Then came the official introduction a half year later and more stories by excited motorcyclists.

Now it's time for the real thing. At last Honda is passing out real test bikes, honest-to-gosh CX500 Turbos like the ones available in stores.

Through it all the Turbo has emerged remarkably unscathed by the year of development. It looks the same now as it did sitting on a chassis dyno in Japan. It works the same as it did on prototype test rides. It hasn't lost any of its unusual features, though a couple of parts have been changed so things fit just a little better.

Being a Honda the Turbo doesn't fit exactly into any of the usual categories of motorcycles. It is an expensive bike, with a list price of $4898. It should remain an unusual bike with an estimated production run this year of about 2500, or one per dealer. It is a powerful bike, with about 78 bhp. It has a fairing, like a touring bike might, except the fairing is not like a normal

touring fairing and there is no way to carry things conveniently on the Turbo.

Fast, expensive motorcycles are normally called Superbikes, but the Honda Turbo is very much different from all of the other Superbikes. It's a Superbike in party clothes.

It is also a showcase for Honda's research and development company. Much is said at new model presentations about Statements. Statements

have a lot to do with Image, which is very important to people in the publicity or marketing arm of large organizations. Statements are usually made with words like Ultimate and Incredible and Serious, none of w hich really have any meaning in the PR dictionary. Statements are a way of explaining something that people wouldn't believe if they were told.

Honda’s Turbo is a Statement. That was explained when the first rides were arranged. What Honda is trying to show is that Honda can make technological marvels that are also motorcycles. The engineers wanted to appeal to more than just motorcyclists and have appealed to people through technology.

Technology, the Turbo has. If some master marketeer compiled a list of all the features possible to put on a motorcycle, the Honda Turbo would come closer to using all the features than any other machine. About the only conventional parts on the machine are the fork stanchion tubes and the levers. Everything else is somehow different from that of other motorcycles, and the more a person looks at the Turbo, the more different everything becomes. It almost seems as if the bike were designed to use as little existing technology and pieces as possible. Either that or Honda has added a new department to register acronyms and other words as trademarks and the rest of the company has been forced to come up with as many acronyms and new words as possible.

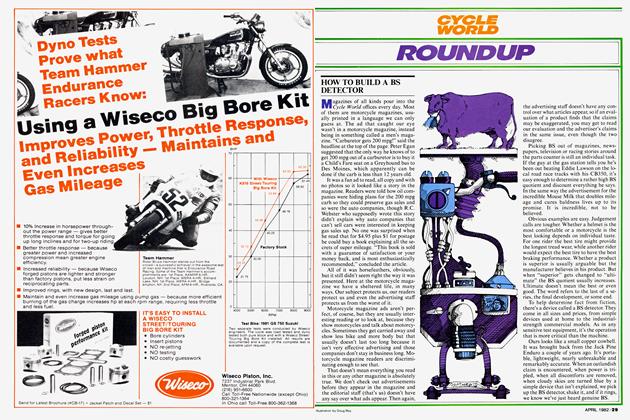

Beginning with the tubeless 18-in. tire in front, the Turbo is equipped with newstyle ComStar wheels, gold anodized and very wide. The front rim is 2.5 in. wide

and the 17-in. rear rim is 2.75 in. Why the smaller diameter wheels on the Turbo isn’t clear, but Honda is equipping its newest road racing machines with 16-in. front tires, so maybe the invention of the Flathead® is not too far away. These wheels are only found on the CX500 Turbo in this country, though a few new models for other countries are using these same wheels without the gold color.

Brakes are not just for slowing a motorcycle, but are part of the front suspension since the development of anti-dive, and the Turbo has taken this one step further than anyone else. The Department of Acronyms (DOA) was turned loose on this one and calls it Torque Reactive AntiDive Control so the fork legs can say TRAC. Unlike the other anti-dive systems Honda’s doesn’t use brake fluid pressure to move valves and increase compression damping in the forks. Instead, the double piston calipers pivot as the brakes are applied, pressing on the valves to restrict compression damping. Other Hondas use one anti-dive fork leg and one conventional leg together. The Turbo has the anti-dive on both fork legs. Honda’s anti-dive is adjustable, which in normal use is about the only difference between this and other anti-dives. A screwdriver can easily turn the small slot-

ted-head adjusters on each fork leg to any of four positions, from soft to hard. Differences between softest and hardest are noticeable, the front end diving much less when set at the firmest position. Interestingly, when left at the firmest setting a variety of riders would comment on the bike and how it worked without ever mentioning the anti-dive control. Yes, it works. But it makes very little difference overall and there are so many other unusual sensations this bike provides for a rider that the anti-dive control becomes one of the least noticeable.

Other than the anti-dive, the Turbo’s front suspension is surprisingly conventional. There are 37mm fork tubes, dual rate springs, air caps linked by a tube for easy adjustment of air pressure, and a moderate rate of damping that is not adjustable except by changing fork oil.

Between the gold anodized fork legs is a fender with air scoops. It’s shaped to wrap behind the fork legs and channel air up to the bike’s radiator.

Suspension travel on the CX Turbo is somewhat shorter than that of the GL500. The front wheel can move up and down 5.1 in. on the Turbo. And the steering head of the Turbo gets tapered roller bearings instead of ball bearings. Steering head angle of the Turbo is a relatively steep 27 °, slightly steeper than the 28 ° of the GL500. Combined with the smaller diameter front tire, trail decreases a similarly small amount.

Unless a few hours are spent with a tool kit no one will ever see most parts of the Turbo’s frame, or even the handlebars for that matter. Everything possible is covered by fiberglass. These fiberglass panels are not parts of a fairing, exactly, but are parts of the motorcycle because the motorcycle isn’t designed to work without all the panels and fiberglass parts. Peel off the panels and the Turbo is a very strange beast. Tubes and sensors and wires create a maze of black lines.

In a press release Honda explains that a disadvantage of a supercharger is the complicated design, while a turbocharger has simple construction, is compact and is lightweight. There may be simple, lightweight, compact turbochargers, but Honda hasn’t built one. Its turbo is massive, heavy and unquestionably the most complex production motorcycle ever attempted.

Like any other turbocharged engine, the Honda Turbo uses exhaust gasses to spin a turbine, which spins a compressor that forces the intake pressure above atmospheric pressure. For generations engines have been classified on the basis

of displacement because a 500cc engine can only inhale 500cc worth of air and fuel each cycle. But if the intake is pressurized at twice atmospheric pressure, for example, then up to lOOOcc worth of air and fuel can be forced into a 500cc engine.

Honda says the maximum boost provided by its tiny IHI turbocharger is 19.3 psi. This is very high, about twice as high as the boost pressure used on most of the turbocharged cars produced today. Most engines can’t survive much over 10 psi without requiring water injection or bomb squads. Of course the normal CX500 engine manages to operate with a 10:1 compression ratio and do it on regular gas. The Turbo uses a much lower compression ratio of 7.2:1. This lower compression combines with the higher boost to yield a more moderate combustion pressure than would be expected by the high boost pressures. Lower compression also results in less power at low engine speeds when there is no boost, which is a very important part of the Honda Turbo’s character, as we’ll see.

Turbochargers do not provide a constant increase in power at all speeds and loads on gasoline engines. This is one of their major problems. At low throttle openings very little air is flowing through

a gas engine and so the turbo is not spinning very fast. This means there is no boost.

When the throttle of a turbocharged engine is opened it takes a short time of operation before gas flow builds up, spinning the turbo faster. Using a smaller diameter turbo can speed up the acceleration of the turbine and also make a turbo more responsive to smaller gas flows, but limits the maximum boost available. So engine designers must pick turbo size to work with engine size and operation. In the past this has been an important problem for turbocharged motorcycles because there were no turbos small enough for engines much under 2000cc. When Honda began the turbo project IHI had just introduced a 50mm turbocharger, much smaller than any available, though still quite large for a 500cc engine. This is the turbo Honda is using.

Like all the other parts of the Honda Turbo, the turbocharger meshes together into a puzzle, only working with all the other parts in this particular motorcycle. Because the turbo is a bit large, boost doesn’t begin until the engine is spinning at 4000 to 5000 rpm and the throttle has been held open for a couple of seconds. This prevents boost from occurring at low engine speeds when the engine would be> most susceptible to detonation because of the high boost pressures. And as boost pressure hits 17.1 psi the wastegate begins to open, also limiting charging pressure at lower engine speeds. It isn’t until the engine has been running under load with full throttle and at a high engine speed that the boost pressure ever reaches 19.3 psi.

Why Honda has chosen this particular combination we can only guess. Most likely the decision to use this particular engine came first. Then came the decision to buy a turbocharger or build one and the newly available IHI unit became the next part of the puzzle. After that everything else just filled in the missing pieces, things like the digital electronic fuel injection and transistorized electronic ignition with advance determined by engine speed and boost pressure.

Fitting the various parts into the motorcycle obviously was quite a chore. The turbocharger was mounted above the engine and in front, where it would be close to the exhaust ports of the V-Twin engine’s heads. Short double wall exhaust tubes lose little heat energy on the way to the turbo, and expansion joints are built into the tubes because of the temperatures involved. Fresh air is routed from the front of the motorcycle, through

an oiled foam air filter in the righthand side of the fairing, through ducting around the front of the fairing and then into the turbocharger.

Exhaust gases that have run through the turbo or through the wastegate are conducted around the righthand side of the bike, under the back of the engine to a large chamber and from there into two mufflers. It doesn’t really need two mufflers, but symmetry is hard to resist.

The fate of incoming fresh air is not so easily explained. After its trip through air filter and turbocharger it goes to a surge tank, which is nothing more than a big plastic box that lets the various waves and pulses in the air settle down. Throttle valves then control the amount of air that flows from the surge tank, through intake tubes, to the cylinder heads. These throttles are controlled just like normal throttle plates in carburetors, but there are no carburetors here. There is a bypass around the throttles. It is opened by an air valve that is temperature controlled, and there are reed valves in this bypass to keep air from running back to the surge tank when the air valve is open. What the air valve does is function like an automatic choke. When the engine coolant is cold a thermostat opens the air valve, causing more air to enter the engine and

causing engine speed to rise to about 2000 rpm.

How the fuel gets into this system is even more intriguing. It starts out in the unusually-shaped 5.3 gal. gas tank. Then it passes through a fuel filter, a fuel pump and a pressure regulator that passes some fuel back to the tank to bleed off excessive fuel pressure. Pressurized fuel is then fed into the intake tubes through fuel injectors that time their opening to control the flow of fuel. In this sense the fuel injectors are like a Thermos: It keeps ice tea cold in the summer and soup hot in the winter . . . but how do it know?

In the case of the fuel injectors, a micro computer tells it. This is no ordinary micro computer. It literally has a sixth sense for controlling fuel flow. Sensors determine engine speed, atmospheric pressure, manifold pressure, throttle opening, intake air temperature and the temperature of the engine coolant. Normally electronic fuel injection systems use relatively simple combinations of sensors to control fuel flow. Because the Honda fuel injection senses not just manifold pressure, but atmo-, spheric pressure and calculates boost pressure from these two, this computer has a few more calculations to make than most. It also works differently at different throttle openings.

At low throttle openings the basic charge duration is determined by engine speed and manifold pressure, with the various temperature probes and pressure sensors altering what the computer tells the fuel injectors. At large throttle openings the length of time the fuel injectors are open is controlled primarily by the engine speed and throttle opening, with temperature and pressure still altering the signal.

Fuel flow is handled by the injectors." These are electrically-triggered plungers operated by the computer. As long as current runs from the computer, the solenoid in the fuel injector holds a plunger open, allowing the fuel into the intake. The pressure regulator holds fuel pressure to 36 psi above manifold pressure, while the*1 fuel pump pressurizes the fuel from 64 to 85 psi.

This basic operation of the fuel injection is direct and electronically simple enough. But there are a number of compensations and special features built into, the computer. For instance if the throttled is moved more than a certain amount within a short period of time more fuel is injected to function as an accelerator pump. And there is low voltage compensation so the injectors discharge for a longer period of time when voltage is low to compensate for the delay in signal, response.

More remarkable is what happens when the computer or its sensors aren’t working properly. Five light emitting diodes on the side of the computer identify problems, when they occur. Normally when the ignition is turned on the fuel system warning light on the instrument panel and the W-light on the computer light up for about 2 sec. If they don’t light there is no power getting to the computer. If there is a problem with the sensors, different combinations of the warning lights appear. Honda has a chart of the possible LED combinations identifying what problem is indicated by each combination. In this way mechanics can look at the side of the computer and match up the lights with the chart to find out which sensor circuit is not functioning right.

Just because a sensor isn’t working doesn’t mean the Honda Turbo won’t run. The earliest electronic fuel injection systems occasionally had sensor failures or wires coming loose and the machine would quit running when that occurred. In this case Honda learned from the auto companies’ mistakes and has added failsafe functions to its computer.

Each sensor failure has its own failsafe response. If, for example, the boost pressure sensor isn’t working, then the computer determines injection time by engine speed and throttle opening. And if those sensors are faulty at the same time then the duration is fixed. Each sensor circuit has the same kind of system. If the sensors don’t work the computer generally assumes the conditions are standard. This may result in somewhat lower performance or less perfect running, but the machine will be able to run back to the dealer.

So far all of this technology depends on the magical computer carefully mounted in the tailpiece of the motorcycle, far from the heat of the engine. Honda is also building up a service procedure for possible computer problems. American Honda is installing test equipment for checking out these computers. And Honda has a trade-in arrangement with the computer manufacturer so that owners of bikes with broken computers will be able to buy rebuilt computers at half of Honda’s cost: $300.

All of this wonderfulness fits on an engine that has remained quite unusual, but has been beefed up where needed. The basic engine cases are standard CX500. Bore is still 78mm, stroke is still 52mm. Pistons are forged of a high-temperature alloy and are shaped to provide the lower 7.2:1 compression ratio. A larger, stronger piston pin is used, and stronger rings are installed. Connecting rods are larger and stronger, and crankshaft bearing journals are larger, for bigger, stronger bearings.

Upper end changes are normal for a turbocharged engine. The head stays the same, but 2mm smaller exhaust valves are used to keep gas velocity high and, besides, volumetric efficiency is not terribly important to supercharged engines. Cam timing is more Honda than Turbo. With 215° of duration on intake and exhaust, measured in Honda’s usual method of 1mm of lift, the Turbo cam timing is about average for a Honda. Normally engineers have worked hard to lower the effective speed range of turbocharged engines and have done so with cam timing set for low engine speeds. Because the Honda Turbo is designed more for high rpm boost than low-speed boost, the cam hasn’t been drastically reworked. Valve seats and guides are a more heat-resistant material than those on the standard CX500. And the cam chain tensioner now uses a locking wedge type of self adjuster. The cam has also been freed of engine cooling duties by the removal of the fan from the end of the cam. Now a thermostatically controlled electric motor pulls air across the radiator when needed.

Oil pump and water pump volumes have been increased to provide greater cooling capacity, and a small oil radiator has been added to the bottom of the engine to help cool the oil. Turbochargers are frequently hard on engine oil because of the heat developed in the turbocharger and its bearings as the shaft spins at 180,000 rpm. Honda specifies SF-rated engine oil for the Turbo, rather than the more normal SE-rated oil.

To handle the greater power from the engine the CX Turbo uses the same size clutch as that used on the GL1000. It’s larger in diameter than the standard CX clutch. Transmission components are mostly the same as on the naturally aspirated 500, but the engagement dogs are forged longer than normal and machined flat on their ends for more positive engagement. This isn’t the same as undercutting the dogs and doesn’t provide the same resistance to popping out of gears, but it’s a much easier and less expensive a machining operation and provides greater gear strength.

Gear ratios on the Turbo are noticeably higher than on the standard CX or GL500 models. With the new clutch primary drive ratio changes from 2.242:1 to 2.055:1. Transmission ratios are all slightly higher for lower engine speeds at the same road speed. Because the Turbo has greater torque and a lower redline it needs the higher gearing to take advantage of the greater power.

Final drive ratio on the Turbo is the same as on all the other shaft-drive Hondas. This is a common unit to everything from the CX500 to the GL1100 and is more than able to handle the power. It is, however, connected to an aluminum swing arm that isn’t shared with any other current Honda model. This aluminum swing arm, connected through a pair of pivoting links to the single spring and

damper results in less rear wheel travel than the single shock unit on the GL500.

Like the GL500, the rear suspension of the Turbo can be adjusted by changing air pressure in the suspension unit. A tube with air valve is hidden under the locking righthand sidecover. There is no damping adjustment.

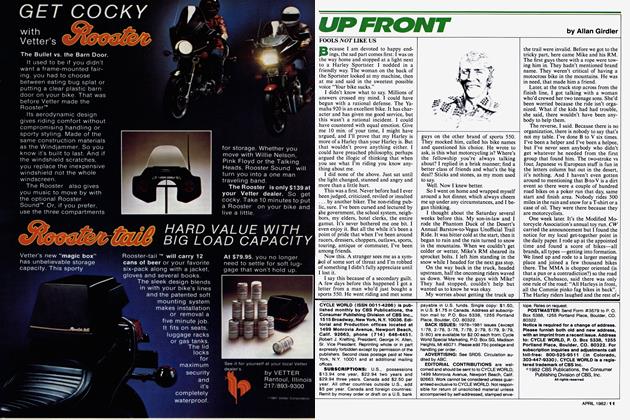

As far removed from motorcycling as the mechanical parts are, the body is even more remote. This is not so much a motorcycle with a fairing as a motorcycle that incorporates body panels. There are lots of them. They are little parts like the fuse cover, and rubber parts like the handlebar cover, and fiberglass parts like the main shell of the fairing and its various hinged panels and removable parts. All together they form the body of the Turbo and house such things as the dash board and the mechanical parts.

On the dash board, or instrument cluster, are a variety of unusual gauges and lights. The 85 mph speedometer and 9000 rpm redline tachometer are normal enough. And the fuel gauge and temperature gauge are becoming more common, but then there’s the digital clock and the fuel system warning light and the fuel reserve light that takes the place of a reserve setting on the fuel petcock. And finally there’s the liquid crystal display above the word TURBO. This would appear to be a boost gauge to anyone who has driven a car with a turbocharger. It is not a boost gauge, though. It is an intake pressure gauge, and that may go back to how the computer senses boost pressure. It subtracts atmospheric pressure from intake pressure, but there is no boost sensor on the motorcycle.

What the intake pressure gauge does is indicate how much air is flowing through the engine. This is a common type of

gauge in aircraft where it is used to determine power output, but it hasn’t been used on most other turbocharger applications yet. And on the Honda Turbo there are no numbers on the gauge, just little green dots. Being a pressure gauge, rather than a boost gauge, there are always little green dots on the gauge. Turn on the ignition and without starting the engine the gauge will indicate atmospheric pressure. That will be four dots lit on both sides of the center dot. Start the engine and two dots on each side will disappear as the intake system operates at idle with a partial vacuum. Open the throttle and more dots appear, making the display appear to be growing wider.

Perhaps the biggest reason for a pressure gauge instead of a boost gauge is that the rider gets to see plenty of dots all the time he’s riding. Right there above the TURBO sign is this little green band of lights. That must mean there’s boost, to the person who thinks in terms of a boost gauge.

Getting real boost is quite another matter. It requires holding the throttle open wide long enough for exhaust gasses to get the turbocharger spinning. It can be done only briefly in 1st gear once the boost does come on because the boost attacks suddenly, throwing the tach needle from 5, where boost first appears, to 9 so fast and with such excitement that a rider can only shift up and try it again.

Under any kind of riding that can be considered normal, the Turbo doesn’t leave a standing start under boost. Even at the dragstrip it is virtually impossible to get boost at launch time. That’s not how the Honda works. Even revving the engine above 5000 doesn’t get boost until there’s enough load on the engine for air flow to build up. So in normal use the rider revs up the engine a bit and lets out the clutch. And the Turbo slowly takes off. It doesn’t rocket away from stops. If the engine is running at a low speed when the clutch is released the bike takes off more slowly. So the rider grabs a handful of throttle and patiently waits as revs steadily climb and all of a sudden everything falls into place as the tach hits 5000 and the TURBO gauge races the tach as both leap to their limits.

It is this two-stage power delivery that is the key to the Turbo. It is the overriding reason that some riders loved riding the bike and others hated it. Highly tuned small engines may be cammy, but nothing has ever had such a Jekyll-Hyde power delivery.

Riding the Turbo slowly is easy. There’s no choke or even a clutch interlock. Just turn on the key, wait a couple of seconds for the fuel pump to build up pressure and hit the starter button. Whatever the temperature, the engine fires immediately. In cold weather the bypass airflow valve runs more air through the engine, which speeds up the idle. When the air temperature is around 40, the bike might idle at 2500 rpm for a couple of miles, until the thermostatic control closes the valve. Then it idles perfectly at around 1000 rpm.

There is no warmup in a conventional sense. There is no choke to push off and nothing but the fast idle reminds you that the engine isn’t running normally. Throttle response is just as if the engine had been running for an hour. There is a slightly greater delay for boost to come on when the engine is first started because the exhaust temperature is still low. But get on the throttle and the temperature gauge can be at the normal range within a mile or two.

Because of the excellent cold running characteristics, the Turbo can work well as a commuter, provided all its character agrees with the rider. There is ample flywheel and no hesitation or stumble anywhere, but the engine is particularly low on power at low engine speeds, moreso than any medium or large-size motorcycle. There is also more exhaust note than any other modern Japanese motor-

cycle has delivered, and it is a particularly pleasing note. The liquid-cooling and shaft drive and body panels and turbocharger all work to damp noises from the engine. So the exhaust system gets to pass on more sound, and the sound of a VTwin engine is wonderful. The closest thing to the sound of the Honda Turbo is the sound of a CX 500 with less restrictive mufflers. It’s not a loud or offensive sound, but it is noticeable enough for the rider and others who can hear the Turbo turning into the parking lot or blasting down a highway.

According to all the sensations the Turbo provides, it is a fast motorcycle. It looks fast, with its pearlescent white paint and gold and orange trim. It sounds fast with the louder than normal exhaust. And certainly a turbocharged motorcycle with a claimed 78 bhp should be fast. And in some ways the Turbo is fast. But it is not one of the all-time greats at the dragstrip. The numbers are 12.64 sec. at 104.40 mph for the quarter-mile and 116 mph for a half-mile top speed. These numbers put the Honda Turbo at the same level as the fast 650 Fours or even a well tuned Kawasaki GPz550. The dragstrip is not where the Honda is happiest.

Any good 750 will be faster in the quarter-mile.

The Turbo’s power characteristics and its weight and its body shape hurt the bike in performance numbers. Getting off the line well requires an elusive combination of practice, skill and luck. Rev too high and pump the throttle in a search for boost and it may come on too quick and throw the bike into the air in a giant wheelie. Miss the secret combination and it bogs. Even when it gets a good launch this is a 571 lb. motorcycle with a substantial fairing. Frontal area is higher than on an unfaired bike with a rider ducking behind the handlebars.

Roll-on performance is similarly unusual. From 40 to 60 mph the Turbo is a bit slow, requiring 5.4 sec. But at about 60 mph the boost attacks and the time from 60 to 80 is only 4.3 sec. Normally motorcycles are faster at the lower speeds where wind resistance is much lower, but the power delivery of the Turbo far outweighs that.

Comfort is another mixed bag of mostly plusses. Here the body of the Turbo does a good job of keeping the rider protected from the air. Particularly well shielded are the legs, torso and other extremities except for the head. A substantial blast of air is directed at the rider’s helmet, making a full-face helmet almost mandatory. The Turbo also comes with a heater. Other riders will be putting on second layers of insulating clothing when the Turbo rider decides it’s time for a heavy jacket. In 40° weather the Turbo rider is just a bit cool with a jacket on. In 60° weather a light jacket is plenty. The day it was 75° the heat was a bit too much. What it will be like crossing the desert in 100° heat we have yet to discover.

The seating position on the Turbo works well with theïairing and the controls. The seat is wide and long, though a bit too sloped down at the front where parts of the seat wrap around the gas tank. Changes in the production seat move the rider back a little bit so taller riders don’t hurt their knees as often on the fairing side panels, though that is still a problem for some riders. Handlebars are moderately low and forward. Riders who prefer a more sporting posture liked the position, though the bars were a bit too low for some riders. Even if the handlebars were visible it wouldn’t be possible to change them because they are designed to fit into the fairing and little else will. At full lock the clearance between the levers and the fairing is already too small for large hands.

Vibration on the Turbo is low. There is some mid-range vibration felt through the handlebars and the seat, but it is of a relatively low frequency and can’t be considered a problem. Controls operate with relatively light pressures and are conveniently located. Throttle return spring tension might be a little higher than desirable, but that’s a small point. The shift lever also requires higher than average

effort and its range of adjustment is narrow because of the way it angles out to the side of the engine rather than forward of the transmission. Maybe that’s why it sometimes popped out of 2nd when the boost came on.

Some of the ancillary items are not what most riders are used to. The mirrors mounted way out on the body provide a smaller view behind the rider and no vision directly behind because they don’t stick out far enough. The absence of a reserve fuel supply is not appreciated. Hiding the clutch adjustment behind another plastic shield on the handlebar seems ridiculous. The single helmet lock is difficult to use and holds a helmet right on the muffler. Sidepanels must be unlocked for removal, which probably protects the tool kit and the leather-bound imitation owners manual, which contains lots of warnings and notes and cautions.

Beside the imitation owners manual is an air pressure gauge for checking suspension settings. Air pressure in the suspension of the Turbo acted mostly as a preload setting, raising or lowering the motorcycle but not having a significant effect on handling except for cornering clearance. We also used higher than average pressure in the back and low pressure in front to adjust the headlight.

Whether air pressure was set high or low the general suspension feeling was much the same. Springing was moderate, damping was ample and the result was a pleasant combination of good ride comfort and stable handling. In some ways the frame geometry is not a good indicator of handling. It has little rake, medium short trail and a fairly long wheelbase. The steep 27° steering head promotes light, quick steering. Narrow handlebars reduce leverage on the bike, requiring more steering effort and lots of weight up high make the Turbo relatively reluctant to change directions without lots of effort.

At low speeds, like around the parking

lot, the Turbo is a handful. It’s heavy and clumsy feeling and the short bars don’t do much to help. Pick up a little speed and the heaviness turns into a stable feeling. The bike holds its line well in corners, becoming more solid as speed builds up. Steering effort remains high, but the motions are short and the bike feels secure at all times. The body work camouflages speed, with only the head in a wind blast.

It could be going 105 as easily as 85 and the speedometer will never tell.

Cornering clearance is good. The pegs don’t ground as easily on the Turbo as they do on the GL500 with similar chassis. The stiller suspension appears to be the reason.

Braking performance is on par with the handling: safe and secure but not outstanding. The double piston calipers on the front have ample power and a very solid feel. And the anti-dive forks can be adjusted so there is little change in the bike's attitude under hard braking. The only problem is that maximum braking performance doesn’t result in especially short stopping distances, another result of the weight involved. And it’s another case of sensations differing from the numbers. Braking power feels stronger than the distances would indicate.

Perhaps that’s why judging this motorcycle proves so difficult. The figures and the feelings just don’t agree. And when it came time for riders to comment on the Turbo the conclusions didn’t agree. Never has a bike received such a split review. Some things we could agree on. The Turbo is too big, too heavy, too expensive, and too complicated. It also manages to work just as it should, without mechanical flaws. Then the agreement ends, mostly in a debate over the boost characteristics

Riders who like that typical Honda top-end surge of power liked the feel of the boost blasting on when the tach hit its stride. Other riders sorely missed low end power that any other big performance machine offers. To some the suddenness of power was fun, to others it was difficult to control and made the bike hard to ride.

The Honda CX500 Turbo is an important motorcycle, though, no doubt about that. Estimated first year sales of 2500 don’t tell the whole story. In Honda’s introduction of the bike spokesmen said. “This motorcycle is to be the spearhead* of the many technological advances Honda is aiming at in the Eighties, the ‘concept bike’ of a totally new category of motorcycles.’’

Not only will Honda be monitoring Turbo sales closely, so will the other motorcycle companies. Success for theTurbo may bring us even more technology. And we're still arguing the merits of that. ®

HONDA CX500 TURBO

$4898

View Full Issue

View Full Issue