Protecting Your Head With Snell '75

A Guide To Helmet Standards and a List of the Best Helmets

John Ulrich

Row after row of battered and broken helmets line shelves in the research lab of a major motorcycle helmet manufacturer near Los Angeles. California. They were returned by grateful riders who survived incredible accidents. and the serve as mute testimony to the effectiveness of a good helmet.

One rider was run over by a car on the expressway. His helmet bore tire tracks and scrape marks from the automobile's differential, yet the rider sustained no major head injuries. Another rider hit an unseen rock in the desert at 80 mph, flew through the air, landed and bounced along underneath the motorcycle. His helmet was completely scraped, cracked in three places, and the liner jerked down into the porthole. But the rider awoke and walked back into his pits with no memory of the crash, suffering only a mild concussion.

The broken specimens illustrate how helmets work, and, coincidentally, the importance of materials and construction used. The job of a helmet is to eat energy, energy which would otherwise reach the brain and injure or kill the rider. The idea is to spread an impact over as great an area as possible, rather than have it concentrated at one point, and to then absorb that impact.

Tests have shown that laminated fiberglass spreads impact better than other matenais, and most of the best helmets todaystill feature a fiberglass/resin shell as first used when the modern crash helmet was invented in 1954 by Bell Helmets. And since an expanded polystyrene liner—first used in the late 1950s—is still the best material for absorbing impact, that’s w hat the best helmets today use.

When impact force exceeds a certain level, the fiberglass shell de-laminates—the layers of fiberglass separating—and in the process, uses up energy from the impact. Energy not absorbed in shell delamination is absorbed by a non-resilient expanded polystyrene foam liner. As the liner crushes, more of the energy transferred from the shell is used up, diminishing impact energy.

The whole point of wearing a helmet is avoiding injury. But knowing what you want isn’t the same thing as getting it. The helmet industry is relatively new'. A vast body of knowledge doesn't exist for designers to refer to. Colleges don’t produce qualified helmet designers with all the answers. Newground is constantly broken; new research must be undertaken. Helmet manufacturers can’t simply strap experimental helmets onto employees, send them out to crash and then see w hat happens.

Instead, manufacturers built helmets to standards, of w hich there are many. Different standards are set by various organizations and may even have different specific aims. Common standards include the American National Standards Institute's Z90.1, the U.S. Department of Transportation (DOT) standard and the Snell Memorial Foundation standard.

There are problems in standard setting. Recent studies of motorcycle accidents on the street have shown that the biggest factor in surv iving a motorcycle accident is whether or not a helmet is worn, not what standard is met by the helmet worn.

Standard setters disagree on requirements. For example, the Snell Foundation standard requires that a helmet not transmit an impact force of more than 200 g’s for more than two milliseconds (2/1000 of a second). But authorities differ on the safe maximum time duration and lack a method for determining the exact survival capabilities of the human brain in regard to impact duration. Some standards don’t have a duration clause, just a maximum impact level. In that respect, standards are often arbitrary.

The Snell Memorial Foundation was established in 1957 in memory of race driver Peter Snell, who was killed while wearing an ineffective helmet. In those days, there were no standards for helmets, which usually were made of linen and resin or cork. No one had devoted serious study to what a helmet should do beyond cover the head, and many drivers and riders died in crashes that would be perfectly survivable with the helmets available today. An amateur race driver and medical man. Dr. George Snively, has headed the Snell Foundation since its establishment. constantly testing, experimenting, gathering medical data. Periodically, Dr. Snively revises the Snell standard as helmet-building technology improves. For example, a helmet which passes the Snell 1975 standard (the most recent), provides 20 percent more impact protection for the wearer than does a helmet which passed the Snell 1970 standard, which was in effect until the 1975 revisions. The Snell standard is pass/fail, and all helmets built to conform to the Snell 1975 standard have a red Snell 1975 sticker—complete with serial number—inside the liner. The Snell Foundation doesn't rate helmets beyond pass/fail. and won't release information on helmets which fail.

The Snell standard is the most difficult standard for helmet manufacturers to meet, and was the first audited standard. Snell representatives buy sample helmets from retail stores at random and make tests, where other standards would (and still do) test helmets supplied by the manufacturer as being representative of all production.

It is possible that there are helmets sold today which could pass the Snell test and yet haven’t been tested. But the only way a buyer can be sure—despite what an eager salesman or public relations man may say—is to look for the Snell sticker.

Recognizing the excellence of the Snell standard, the American Motorcyclist Association (AMA) and other racing groups in the U.S. require that competitors wear helmets certified by the Snell Foundation.

Lab testing for the Snell standard measures a helmet's impact absorption, chin strap retention and resistance to shell penetration.

In impact tests, a metal form shaped and weighted to approximate an average human head is fitted with an accelerometer connected to a computer system. With a helmet strapped on, the form is raised three meters and dropped on an anvil. The accelerometer measures impact force in g’s transmitted through the helmet to the head form. Anvil shape is changed to simulate different specified impact surfaces, as if the helmet hit against a flat road, a street curb, a curved rock. etc. Head form position is altered to change impact location on the helmet, from one side to the other, front or rear.

In penetration testing, a pointed weight (6.67 lb.) drops from one meter onto the helmet, which must not allow penetration.

In retention tests, the helmet is placed on a head form and strapped onto a stationary bar. A hydraulic pump raises the head form while pressure is indicated by one gauge and stretch by another gauge. To pass, a helmet retention system must endure a 300-lb. force over a period of two minutes without breaking or elongating more than one inch.

To earn Snell approval, it isn't enough for samples of a helmet model to pass the impact, penetration and retention tests. Any given sample of that helmet model must be able to pass the same tests after being soaked in water for 24 hours, or frozen for 24 hours, or baked in an oven for 24 hours.

In spite of all the effort expended to improve helmet performance in terms of impact spreading and absorption, that doesn’t mean that a rider wearing a helmet is indestructible.

Even the highest standard—the Snell 75—based upon the best available technology, requires that helmets protect the brain from direct impacts of about 18 mph. The best helmet in the world will not save a rider's life in the case of a 25 mph headfirst collision with a solid, unmoving, nonyielding object or surface.

Happily, few linear (straight line) impacts reach that level in real life. A rider may tumble down the Daytona straightaway at 175 mph. but the impacts against the pavement are glancing and sliding, and as long as they don’t exceed the capabilities of the helmet to absorb linear impact, then the rider may survive—as several have.

A rider may slam into the side of a car or truck at 40 mph. but he reaches out w ith his hands, or his shoulder hits first, or the sheet-metal side of the car or truck dents inward; linear impact force again fails to exceed the helmet’s capabilities, and the rider lives.

There are several things to consider when buying a helmet. Any helmet is better than no helmet, but once you’ve passed that point it's a thinking-man's decision as to howmuch protection you want. Second, racing organizations specify that helmets must meet Snell 1975 standards. Third, only fiberglass-and-resinshell (or, in the case of certain Shoei and Arai models, a combination of fiberglass with aramid or carbon fiber for equal strength and less weight) helmets have passed Snell 1975 at this time. Fourth, every helmet design which has passed the Snell Foundation tests comes with a Snell 1975 sticker inside the liner, in plain view.

We always wear helmets when riding, but we look for the Snell sticker first.

Arai S-75

Open face, fiberglass construction. Available in small, medium, large, extra large. $62.95 in white, $2 extra for silver, $5 extra for black. Passes Snell 1975.

Arai X-75

Full face, fiberglass construction. Available in small, medium, large, extra large. $72.95 in white, $2 extra for silver, $5 extra for black. Passes Snell 1975.

Arai R-7

Open face. Complex Laminate Construction. (CLC) similar to usual fiberglass construction, but utilizes polymer fiber for equal strength and weight reduction. Available in small, medium, large, extra large. $98.95 in white only. Passes Snell 1975.

Arai RX-7

Full face. Complex Laminate Construction, similar to usual fiberglass construction, but utilizes polymer fiber for equal strength with weight reduction. Available in small, medium, large, extra large. $130.95 in white only. Helmet shown has custom paint job similar to Arai Vintage Series. The RX-7 passes Snell 1975 and comes in white only at this writing. The fancy-paint Vintage Series does not pass Snell 1975.

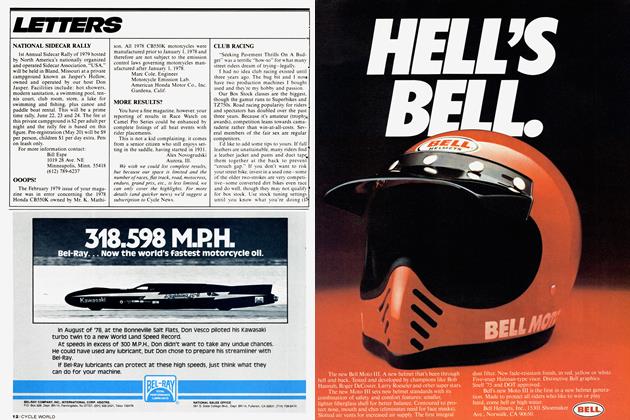

Bell Magnum II

Open face. Fiberglass construction. Available in 6 1/2, 6 5/8 , 6 3/4, 6 7/8, 7, 7 1/8, 7 1/4, 7 3/8, 7 1/2, 7 5/8, 7 3/4 and 7 7/8 hat sizes. $85.95 in white, yellow, orange, black, silver, blue or red. Passes Snell 1975.

Bell Star II

Full face. Fiberglass construction. Available in 6 3/4, 6 7/8, 7, 7 1/8, 7 1/4, 7 3/8, 7 1/2, 7 5/8, 7 3/4, 7 7/8 hat sizes. $109.95 in white, yellow, orange, black, silver, blue or red. Passes Snell 1975.

Bell Moto III

Full face motocross and off road helmet to accommodate goggles. Fiberglass construction. Available in 6 3/4, 6 7/8, 7, 7 1/8, 7 1/4, 7 3/8, 7 1/2, 7 5/8 hat sizes. $104.95 in white, yellow or red. Passes Snell 1975.

Electro Pro Series 2

Open face. Fiberglass construction. Available in 6 7/8, 7, 7 1/8, 7 1/4, 7 3/8, 7 1/2, 7 5/8 hat sizes. $77.95 in white, yellow or red. Passes Snell 1975.

Electro Custom Series 2

Open face. Fiberglass construction. Available in 6 7/8, 7, 7 1/8, 7 1/4, 7 3/8, 7 1/2, 7 5/8, $89.95 in combinations of yellow and red, yellow and black, red and white and blue, or yellow and blue. Passes Snell 1975.

Fury 500 Pro

Full face. Fiberglass construction. Available in small, medium, large, extra large. $82.50 in white, black, red, blue, yellow or silver. Passes Snell 1975.

Harley-Davidson

Open face. Fiberglass construction. Available in small, medium, large, extra large. $75.95 in Harley-Davidson orange. black, and white team color combination. Passes Snell 1975.

Harley-Davidson

Full face. Fiberglass construction. Available in small, medium, large, extra large. $99.95 in orange. black and white combination. Passes Snell 1975.

Fury 400 Pro

Open face. Fiberglass construction. Available in small, medium, large, extra large. $69.29 in white, black, red, blue, yellow or silver. Passes Snell 1975.

Hondaline Britestripe Stag

Open face. Fiberglass construction. Available in small, medium, large, extra large. $60.50 in white, black, silver, presto red, blue, candy red. Britestripe Stag passes Snell 1975, while economy model Stag (without reflective striping) does not due to differences in construction. Red, white and blue Team Honda Stag ($60.50) also passes Snell 1975.

Hondaline Britestripe Hawk

Full face. Fiberglass construction. Available in small, medium, large, extra large. $84.95 in white, black, silver, presto red, blue, candy red. Britestripe Hawk passes Snell 1975, while economy model Hawk (without reflective striping) does not due to differences in construction. Red, white and blue Team Honda Hawk ($84.95) also passes Snell 1975.

Hondaline CBX Super Sport

Full face. Fiberglass construction. Avail able in small, medium, large, extra large. $110.00 in silver or maroon. Passes Snell 1975.

KRW Preferred Model 2500

Open face. Fiberglass construction. Available in sizes B (6 3/4 to 6 7/8), C (7 to 7 1/8), D (7 1/4 to 7 3/8), E (7½ to 7 5/8). $81.95 in white, black, or silver. Passes Snell 1975.

KRW Preferred Model 5000

Full face. Fiberglass construction. Avail able in sizes B (6 3/4 to 6 7/8), C (7 to 7 1/8), D (7¼ to 7 3/8), E (7 1/2 to 7 5/8). $110.95 in white, black, or silver. Passes Snell 1975.

Shoei S-12

Full face. Fiberglass construction. Avail able in small, medium, large, extra large. $87.95 in white, black, orange. yellow, red. blue, metallic red, metallic blue, metallic silver. Passes Snell 1975.

Shoei S-22

Open face. Fiberglass construction. Available in extra small, small, medium, large. extra large. $67.95 in white, black, orange, yellow, red, blue, metallic red, metallic blue, metallic silver. Passes Snell 1975.

Shoei S-30

Full face. Carbon fiber and fiberglass construction. Available in small, medium, large, extra large. $129.95 in white, black, orange, yellow, red, blue, metallic red, metallic blue, metallic silver. Passes Snell 1975.

Shoei ZR

Full face. Fiberglass and aromatic polyamide construction. Available in small, medium, large and extra large. $105.95 in white, black, orange, yellow, red, blue, metallic red, metallic blue, metallic silver. Passes Snell 1975.

Shoei S-31

Open face. Carbon fiber and fiberglass construction. Available in extra small, small, medium, large, extra large. $109.95 in white, black, orange, yellow, red, blue, metallic red, metallic blue, metallic silver.

Shoei ZV

Open face. Fiberglass and aromatic polyamide construction. Available in small, medium, large, and extra large. $85.95 in white, black, orange, yellow, red, blue, metallic red, metallic blue, metallic silver. Passes Snell 1975.

Shoei ZG

Full face. Fiberglass and aromatic polyamide construction. Available in small, medium, large, extra large. $109.95 in white, black, orange, yellow, red, blue, metallic red, metallic blue, metallic silver. Passes Snell 1975.

Shoei ZX

Full face motocross and off-road helmet to accommodate goggles. Fiberglass and aromatic polyamide construction. Available in small, medium, large and extra large. $109.95 in white, black, orange, yellow, red, blue, metallic red, metallic, blue, metallic silver. Passes Snell 1975.

continued on page 209

continued from page 168

Simpson Model 70

Open face. Fiberglass construction. Available in 6 7/8, 7, 7 1/8, 7 1/4, 73/8, 7 1/2, 75/8, 7 3/4 hat sizes. $76.95 in silver or black. Passes Snell 1975.

Simpson Model 60

Full face. Fiberglass construction. Avail `able in 6 7/8, 7, 7 1/8, 7¼, 7 3/8, 7½, 7 5/8, 7 3/4 hat sizes. $99.31 in silver or black. Passes Snell `~75. >

Simpson Model 50

Full face motocross helmet to accommodate goggles. Fiberglass construction,. Available in 67/8, 7, 7 1/8, 71/4, 7 3/8, 7 1/2, 75/8, 73/4 hat sizes. $99.31 in black or yellow. Passas Snell 1975.

Suzuki Mark VII

Open face. Fiberglass construction4. Available in small, medium, large. extr~ large. $59.75 in yellow. Passes Snell 1975.

Yamaha SZ

Open face. Fiberglass construction. Available in small, medium, large, extra large. $55.50 in white, black, red, silver, yellow, blue. Passes Snell 1975.

Yamaha FZ

Full face. Fiberglass construction. Available in small, medium, large, extra large. $77.95☺ in white, black, red, silver, yellow or blue. Passes Snell 1975.