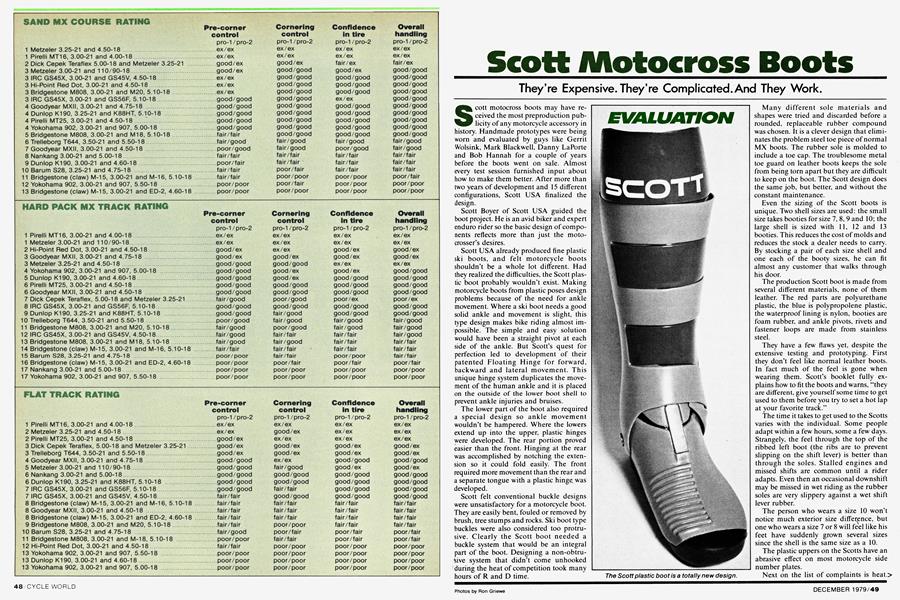

Scott Motocross Boots

EVALUATION

They’re Expensive. They’re Complicated. And They Work.

Scott motocross boots may have received the most preproduction publicity of any motorcycle accessory in history. Handmade prototypes were being worn and evaluated by guys like Gerrit Wolsink, Mark Blackwell, Danny LaPorte and Bob Hannah for a couple of years before the boots went on sale. Almost every test session furnished input about how to make them better. After more than two years of development and 15 different configurations, Scott USA finalized the design.

Scott Boyer of Scott USA guided the boot project. He is an avid biker and expert enduro rider so the basic design of components reflects more than just the motocrosser’s desires.

Scott USA already produced fine plastic ski boots, and felt motorcycle boots shouldn’t be a whole lot different. Had they realized the difficulties, the Scott plastic boot probably wouldn’t exist. Making motorcycle boots from plastic poses design problems because of the need for ankle movement. Where a ski boot needs a good solid ankle and movement is slight, this type design makes bike riding almost impossible. The simple and easy solution would have been a straight pivot at each side of the ankle. But Scott’s quest for perfection led to development of their patented Floating Hinge for forward, backward and lateral movement. This unique hinge system duplicates the movement of the human ankle and it is placed on the outside of the lower boot shell to prevent ankle injuries and bruises.

The lower part of the boot also required a special design so ankle movement wouldn’t be hampered. Where the lowers extend up into the upper, plastic hinges were developed. The rear portion proved easier than the front. Hinging at the rear was accomplished by notching the extension so it could fold easily. The front required more movement than the rear and a separate tongue with a plastic hinge, was developed.

Scott felt conventional buckle designs were unsatisfactory for a motorcycle boot. They are easily bent, fouled or removed by brush, tree stumps and rocks. Ski boot type buckles were also considered too protrusive. Clearly the Scott boot needed a buckle system that would be an integral part of the boot. Designing a non-obtrusive system that didn’t come unhooked during the heat of competition took many hours of R and D time.

Many different sole materials and shapes were tried and discarded before a rounded, replaceable rubber compound was chosen. It is a clever design that eliminates the problem steel toe piece of normal MX boots. The rubber sole is molded to include a toe cap. The troublesome metal toe guard on leather boots keeps the sole from being torn apart but they are difficult to keep on the boot. The Scott design does the same job, but better, and without the constant maintenance.

Even the sizing of the Scott boots is unique. Two shell sizes are used: the small size takes booties for size 7, 8, 9 and 10; the large shell is sized with 11, 12 and 13 booties. This reduces the cost of molds and reduces the stock a dealer needs to carry. By stocking a pair of each size shell and one each of the booty sizes, he can fit almost any customer that walks through his door.

The production Scott boot is made from several different materials, none of them leather. The red parts are polyurethane plastic, the blue is polypropolene plastic, the waterproof lining is nylon, booties are foam rubber, and ankle pivots, rivets and fastener loops are made from stainless steel.

They have a few flaws yet, despite the extensive testing and prototyping. First they don’t feel like normal leather boots. In fact much of the feel is gone when wearing them. Scott’s booklet fully explains how to fit the boots and warns, “they are different, give yourself some time to get used to them before you try to set a hot lap at your favorite track.”

The time it takes to get used to the Scotts varies with the individual. Some people adapt within a few hours, some a few days. Strangely, the feel through the top of the ribbed left boot (the ribs are to prevent slipping on the shift lever) is better than through the soles. Stalled engines and missed shifts are common until a rider adapts. Even then an occasional downshift may be missed in wet riding as the rubber soles are very slippery against a wet shift lever rubber.

The person who wears a size 10 won’t notice much exterior size difference, but one who wears a size 7 or 8 will feel like his feet have suddenly grown several sizes since the shell is the same size as a 10.

The plastic uppers on the Scotts have an abrasive effect on most motorcycle side number plates.

Next on the list of complaints is heat.>

They don’t breath like cowhide and me accumulated perspiration can't escape. Thus their waterproof claim almost works against them. Might as well be wet from creek water as sweat. After a hard day’s ride in hot weather, it is possible to accumulate about a half pint of water in each boot. We’ve considered drilling a couple of drain holes in each boot to let the trapped perspiration out!

Repair is the next problem. Although Scott sells a dealer repair kit to cover buckle parts and minor problems, sole replacement requires shipping them back to Scott’s service center. Turn around time is claimed to be only two weeks. Even so, a rider could be forced to dig out his old leather jobs until the plastics are returned. Luckily repair shouldn't be required often. We had a major problem with one pair of ours. The right boot broke in the instep area from kick starting a 450 Maico. The one that broke was an early production pair and Scott has since increased the plastic thickness in this area of the boot. We pulled the nylon liner loose from the lower shell on the same pair, but we feel this was caused from carrying the boots by the liners. Our fault, not the boots.

So much for the negative aspects. Now the good stuff.

Probably the biggest reason for wearing boots while riding motorcycles is the protection they provide. And the Scott boots provide the wearer with superior protection, in our opinion. The sole is shaped and rounded so it glides over the ground instead of catching on it and kicking your foot back. The polyurethane lower is nearly crush-proof and comparable to encasing your foot in a plastic cast. And the upper is nearly as strong. If a hard blow, such as a thrown rock or crashed bike, contacts the Scott boot, the force of the blow is spread across a wide area of the boot and thus partially absorbed. The plastic doesn’t dent like leather and most encounters with objects go almost unnoticed. The thick foam sizing liner further isolates the wearer’s foot from harm and furnishes a snug, comfortable fit.

Most riders notice a big difference in shock transmitted back through the foot pegs when wearing Scotts. It is especially noticeable over large jumps. The boot shell spreads the load over the whole bottom of the boot, eliminating the sharp blow to the instep.

Forget the messy oiling and waterproofing leather requires. Just hose the mud and dirt off, and hang them up to dry. If you are in a hurry, remove the bootie so it can dry quicker. After they dry, squirt a little Armor All or other comparable chemical on them. The plastic will never get waterlogged or deteriorate from water exposure. Theoretically one pair of Scott boots should last almost indefinitely with minimal care and repair. One of our original pair has been worn by a pro motocrosser for six months with zero repair.

With a retail price of $180, they aren’t cheap. Not initially anyway. But over a period of a couple of years a rider could come out way ahead. With some leather boots going for $130, and needing replacement up to three times a year at the pro motocross level, the Scotts start sounding like a bargain. We have used our plastic Scotts for six months now and the test riders wouldn’t be without them. SI

View Full Issue

View Full Issue