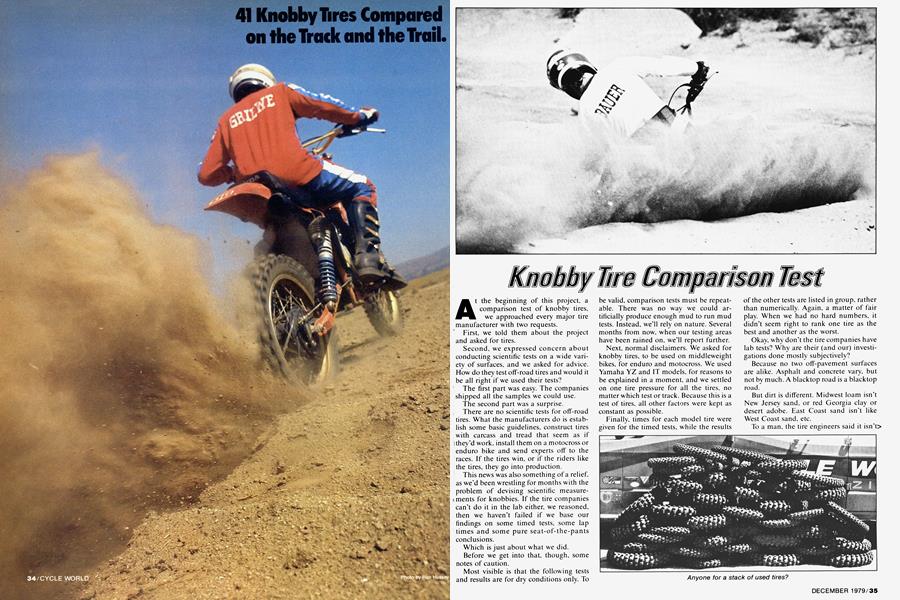

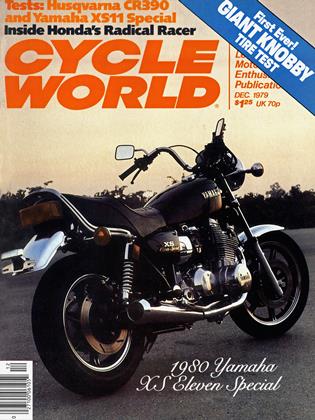

41 Knobby Tires Compared on the Track and the Trail.

Knobby Tire Comparison Test

At the beginning of this project, a comparison test of knobby tires, we approached every major tire manufacturer with two requests. First, we told them about the project and asked for tires.

Second, we expressed concern about conducting scientific tests on a wide variety of surfaces, and we asked for advice. How do they test off-road tires and would it be all right if we used their tests?

The first part was easy. The companies shipped all the samples we could use.

The second part was a surprise.

There are no scientific tests for off-road tires. What the manufacturers do is establish some basic guidelines, construct tires with carcass and tread that seem as if ) they’d work, install them on a motocross or enduro bike and send experts off to the races. If the tires win, or if the riders like the tires, they go into production.

This news was also something of a relief, as we’d been wrestling for months with the problem of devising scientific measureaments for knobbies. If the tire companies can’t do it in the lab either, we reasoned, then we haven’t failed if we base our findings on some timed tests, some lap times and some pure seat-of-the-pants conclusions.

Which is just about what we did.

Before we get into that, though, some notes of caution.

Most visible is that the following tests and results are for dry conditions only. To be valid, comparison tests must be repeatable. There was no way we could artificially produce enough mud to run mud tests. Instead, we’ll rely on nature. Several months from now, when our testing areas have been rained on, we’ll report further.

Next, normal disclaimers. We asked for knobby tires, to be used on middleweight bikes, for enduro and motocross. We used Yamaha YZ and IT models, for reasons to be explained in a moment, and we settled on one tire pressure for all the tires, no matter which test or track. Because this is a test of tires, all other factors were kept as constant as possible.

Finally, times for each model tire were given for the timed tests, while the results of the other tests are listed in group, rather than numerically. Again, a matter of fair play. When we had no hard numbers, it didn’t seem right to rank one tire as the best and another as the worst.

Okay, why don’t the tire companies have lab tests? Why are their (and our) investigations done mostly subjectively?

Because no two off-pavement surfaces are alike. Asphalt and concrete vary, but not by much. A blacktop road is a blacktop road.

But dirt is different. Midwest loam isn’t New Jersey sand, or red Georgia clay or desert adobe. East Coast sand isn’t like West Coast sand, etc.

To a man, the tire engineers said it isn’t> possible to design a knobby tire that's best for all surfaces.

Instead, their goal is to design either a tire that works well—not perfectly—on all surfaces, or to offer a choice of tire for mud, sand, rock or dirt.

These men know their business. They’re also human, as are the test riders, so what we got when we collected all 41 tires was an assortment of practical decisions, the results of 14 engineering departments balancing grip against wear, sand against mud, flexibility against strength.

A good tire depends on the success of tw'o elements: the carcass and the tread.

The tread is visible and one can drawsome primary conclusions from looking at competing models. Most knobbies use alternating rows, four knobs, five knobs, etc. Most of the current tires are nearly square in cross-section, with high side knobs that don’t wrap around to the sidewall. The newer designs have patterns on the knobs, in the form of wavy lines, straight lines, cross hatching or dimples, the theory being that it’s the edges that grip the surface so the more edges you have, the more grip you get.

There are differences between tires designed for solid dirt and tires designed for looser surfaces. Best example here is the Dunlop K190. an all-round design, and the Dunlop K88HT. built for hard terrain. The 190 has dimples on large blocks spaced apart, the HT has flat-topped knobs, smaller and placed closer together.

Tire engineers say there are also different patterns for sand and mud. Blocks for a mud tire should be staggered, they say. with the rows overlapping so the tread gears into the mud rather than letting the mud slide past. Sand tires should have a clear path between knobs, because the bike runs through sand.

The charts show variation in knob height. Another trade-off. As a general rule, taller knobs work in sand while flexing too much for best performance on hard pack.

Carcass design is less easy to test. All the tires in this group are cross-ply construction. with tube. Some use nylon cords and some have rayon, and most are either fourplv or four-ply rated, based on standards for weight capacity. The compound, the rubber-substitute material used for carcass and tread, is a chemical mix. We cannot analyze them, but we did check each w ith a durometer, to determine relative rubber hardness.

The tires in this group are the same general sizes, but as the measurements show-, they differ in tread width, section height and diameter.

The dimensions determine w hat the engineers call displaced volume, the space contained by the tire.

There is variation in volume, and in sidewall stiffness, aspect ratio and so forth, which is why two tires w ill react differently with identical air pressure.

Point here is, carcass is as. important as tread, while being as different and much harder to evaluate.

Our tests were laid out to include as many conditions, that is, different surfaces, as possible. We used three Yamaha YZ250s and one IT400. This combination was picked because the bikes are popular and because we could swap wheels among them. (The IT was needed by virtue of its odometer and speedometer.)

Modifications to the bikes were minor: a calibrated VDO speedometer went on the IT and the final gearing was changed to match the motocrossers. Suspensions were adjusted to the same on all of the machines and our pro motocrossers suggested using 12 psi of air pressure in both front and rear tires throughout the test.

Saddleback Park was chosen for the test site. The main motocross course was used for the hard ground MX test, and a sand MX course was laid out in a large sand trap at the back of the park. The two courses were tied together with trails, to furnish a trail impression. We used Saddleback’s flat track as a test. Not that anyone buys knobby tires for flat track use, but a flat track does simulate fire roading. We also used the center of the flat track for our acceleration and braking tests. Two pro motocrossers, Steve Bauer and Don Griewe, rode for the input from each MX track and the flat track. An expert desert rider. Bill Wolf, rode the IT during the acceleration and braking tests.

The testing was conducted in the following order: Both pro motocrossers raced around Saddleback’s hard ground MX course for five laps, switched bikes and raced for another five laps. Their impressions were recorded and they hit the trail for the sand track. Five laps on each bike around the sand track and impressions again recorded. Another trail led them back to the flat track and five laps on each machine for each rider. More results recorded and the wheels from the motocrossers removed. The next set of test tires and wheels were then installed on the MX bikes. The wheels removed from the motocrossers were installed in matched pairs on the IT. Acceleration tests were next; a minimum of five runs from dead stop to measured 100-ft. marker. Any run that appeared exceptionally fast and couldn’t be closely duplicated was ignored, then the fastest time recorded.

Next came braking. Full-lock stops from an indicated 30mph on the VDO were repeated a minimum of five times. Any stops that were exceptionally short and couldn’t be duplicated closely were discarded and the shortest repeatable distance logged.

The double entry below each track test section represents each pro-rider’s input. In some cases they agreed, in others they differed quite a bit. We expected differences of opinion—that’s the main reason for using two riders instead of one.

Testing the 21 sets of knobbies took over three weeks and Jerry Vucci and Tim Buck are ready to challenge all comers for the world tire changing championship.

CONCLUSIONS

The accompanying charts list the winners of each test starting with first at the top (except for trail impressions). Several ties were encountered, including first place on the hard pack and sand MX courses. We had more ties on the sand MX course than any other test. Either more models work right in sand or the faults aren’t as noticeable, we're not sure which.

Because testing was conducted with matched pairs of tires, some brands of tires placed lower than expected. Front tire performance is much more important than rear tire performance on a dirt bike but, strangely, only a few front tires were considered really good. Most of the rear tires would have finished higher in the results if front tire performance had been equal to the rear. A rear tire that slips a little or doesn’t quite bite perfectly, but sells for maybe half the price of the perfect rear tire, can be a wise choice for the trail rider or the person on a tight budget, if a really good tire is used on the front. But a marginal rear tire combined with a marginal front could cause an unnecessary fall. A slippery rear tire can easily be compensated for, a skating front tire isn’t so easy to allow for and can turn a fun ride into a fear ride. The lesson here is simple; Buy the best possible front tire, regardless of price. Buv the less perfect tire for the rear if your budget is tight or if the tire is on sale. Which front tires did our pro testers prefer“? The Pirelli MT16 and MT25, 3.00-21. Metzeier 3.00 and 3.25-21, Hi-Point 3.0021, and Goodyear MX1I. 3.00-21 all did well.

The tires that came out with high ratings on the MX courses were, in many cases, near the middle or bottom of the results in the braking and acceleration tests. The acceleration chart could be misleading if not studied carefully. As an example; the difference between first and seventh place is only .09 sec., meaning the fastest tire is a little over 3 ft. ahead of seventh at the 100ft. mark.

Results of the braking test were equally close between the first seven places. The biggest difference between any of the positions was between first and second, where a whopping 3.6 ft. separated the two. But second through seventh was separated by less than 2 ft. Control of the motorcycle is as important as quick stops and the first> nine tires were all rated excellent for control.

One brand of tire consistantly came up at the top of our result sheets—Pirelli. The MT16s tied for first on the hard pack course, tied for first on the sand MX course, won the top spot on the flat track test, placed second in the braking test, and got seventh in the acceleration test. The Pirelli MT25s didn’t fare as well as the MT16s but won the acceleration test. Metzelers also finished consistently high in-the MX course tests. The 3.25-21 combined with a 4.50-18 rear tied with the Pirellis for first on the sand course, grabbed second on the flat track, and the low profile 3.00-21 and 110/90-18 Metzelers tied for first on the hard pack MX course. However, the Metzelers didn’t finish nearly as well as the Pirellis on the braking or acceleration tests. The 3.25/ 4.50 Metzeler combination finished next to last on the braking and acceleration tests.

Goodyear’s new MXII also finished well in several tests and took second and third place honors in the drag tests. Other makes worthy of mention are the Yokohama 902 and 907 models that teamed to stop substantially quicker than the others and also accelerated rapidly. The Dick Cepek Teraflex (Cepek is an offroad supplier for four wheel drive vehicles), with its full 1-in. knobs proved to be the sleeper of the group. It finished third on the flat track and second on the sand track.

Our cross-country impressions were the least detailed test but tended to indicate cross country tire choice is much less critical than the choice for MX as 10 of the models made the excellent list.

Our knobby tire test was meant to test tires at their extremes as fairly and accurately as possible. We feel we have accomplished this. Due to personal preferences, soil types, riding conditions, and different demands placed on tires by bike design and engine size, the winners of our different events may not be the absolute best for your use, but we feel the test will be helpful when it comes time for new shoes for the old scoot. SI

BRAKING

ACCELERATION RATING

CROSS COUNTRY IMPRESSION

Excellent Bridgestone M808, 3.00-21 and M20, 5.10-18 Dunlop K190, 3.25-21 and K88HT, 5.10-18 Dunlop K190, 3.00-21 and K190, 4.60-18 Hi-Point Red Dot, 3.00-21 and 4.50-18 Metzeier 3.25-21 and 4.50-18 Metzeier 3.00-21 and 110/90-18 Nankang 3.00-21 and 5.00-18 Pirelli MT16, 3.00-21 and 4.00-18 Pirelli MT25E, 3.00-21 and 4.50-18 Yokohama 902, 3.00-21 and 907, 5.00-18

Good Barum S28, 3.00-21 and 4.75-18 Bridgestone M808, 3.00-21 and M18, 5.10-18 Dick Cepek Teraflex, 5.00-18 (rear only available) Goodyear MXII, 3.00-21 and 4.75-18

Fair Goodyear MXII, 3.00-21 and 4.50-18 IRC GS45X, 3.00-21 and GS56F, 5.10-18 Trelleborg T644, 3.50-21 and 5.50-18 Yokohama 902, 3.00-21 and 907, 5.50-18

Poor Bridgestone (claw) M15, 3.00-21 and ED-2, 4.60-18 Bridgestone (claw) M-15, 3.00-21 and M-16, 5.10-18 IRC GS45X, 3.00-21 and GS45V, 4.50-18

SAND MX COURSE RATING

HARD PACK MX TRACK RATING

FLAT TRACK RATING

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsUpfront

December 1979 By Allan Girdler -

Letters

LettersLetters

December 1979 -

Departments

DepartmentsCycle World Roundup

December 1979 -

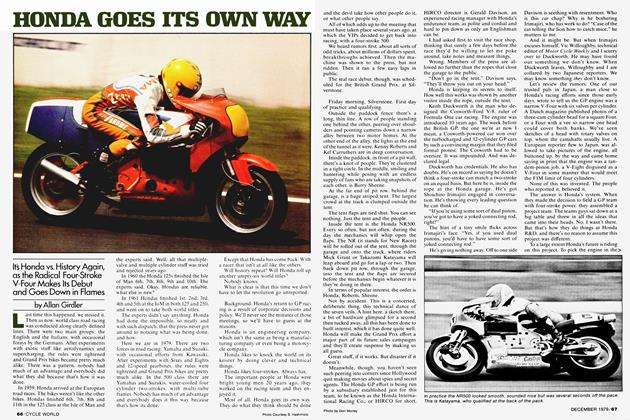

Features

FeaturesHonda Goes Its Own Way

December 1979 By Allan Girdler -

Features

FeaturesCold Storage

December 1979 By Glen Brinks -

Competitoin

CompetitoinLaguna Seca Formula 750 Road Race

December 1979 By Kent Peterson