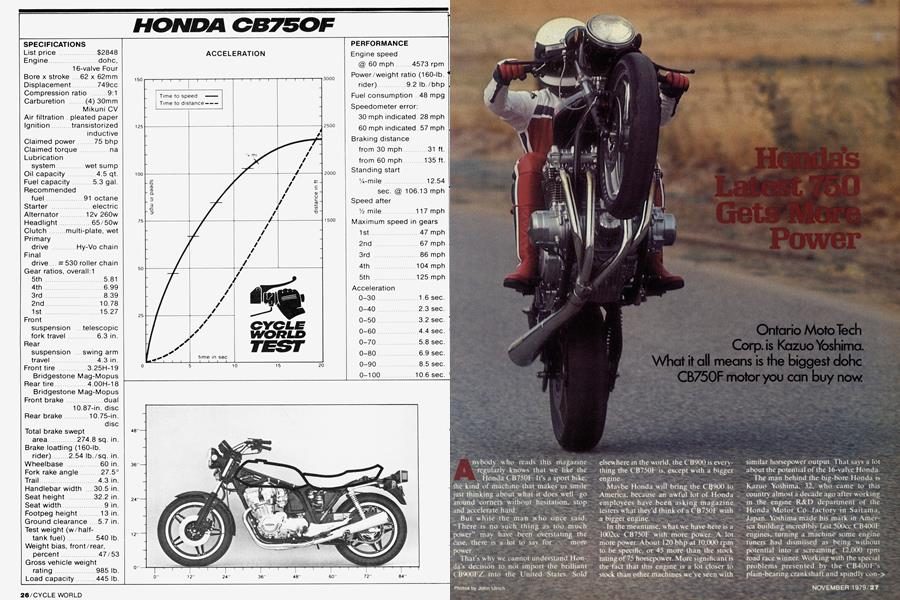

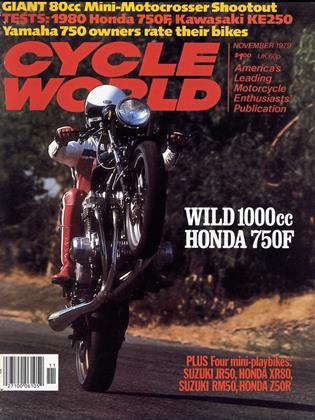

Honda's Latest 750 Gets More Power

Ontario Moto Tech Corp. is Kazuo Yoshima. What it all means is the biggest dohc CB750F motor you can buy now

Anybody who reads this magazine regularly knows that we like the Honda CB750F. It’s a sport bike, the kind of machine that makes us smile just thinking about what it does well—go around corners without hesitation, stop and accelerate hard.

But while the man who once said. “There is no such thing as too much power" may have been overstating the case, there is a lot to say for ... more power.

That's why we cannot understand Honda's decision to not import the brilliant CB900FZ into the United States. Sold elsewhere in the world, the CB900 is everything the CB750F is, except with a bigger engine.

Maybe Honda will bring the CQ900 to America, because an awful lot of Honda employees have been asking magazine testers w hat they'd think of a CB750F with a bigger engine.

In the meantime, w hat we have here is a 1002cc CB750F with more power. A lot more power. About 120 bhp at 10.000 rpm to be specific, or 45 more than the stock rating of 75 horsepower. More significant is the fact that this engine is a lot closer to stock than other machines we've seen with similar horsepower output. That says a lot about the potential of the 16-valve Honda.

The man behind the big-bore Honda is Kazuo Yoshima, 32, who came to this country almost a decade ago after working in the engine R&D department of the Honda Motor Co. factory in Saitama, Japan. Yoshima made his mark in Amer* ica building incredibly fast 500cc CB400F engines, turning a machine some engine tuners had dismissed as being without potential into a screaming, 12,000 rpm road race w inner. Working with the special problems presented by the CB400F's plain-bearing crankshaft and spindly connetting rods prepared Yoshima for both the CBX and the new Honda 750.

The result of Yoshima’s work with the 750 is seen on these pages.

Yoshima planned to enter the bike in American Motorcyclist Association (AMA) Superbike Production races, but ran out of time trying to assemble pieces and complete development work before the season ended. In fact, two weeks before we rode the bike, the engine hadn't been assembled for the first time and Yoshima was still fabricating parts. Because frame and suspension work hasn’t been completed and tested, we will concentrate on the engine modifications. Readers should realize that although destined for the racetrack, the engine is still in the early stages of development and requires much work to be a competitive Superbike. However, many of the changes already made and the parts already installed are applicable to—and available for—street use. In many cases, the parts are the first of their kind available for the 749cc dohc Honda 750.

Part of the extra displacement comes from 68mm, 168-gram cast pistons manufactured to Yoshima’s specifications by the same Japanese firm that builds OEM Honda pistons. The stock 62mm cast piston weighs 155g. Each piston has two conventional steel, 1.2mm-thick compression rings and one three-piece oil-control ring. Compression ratio without milling the head is 11.3:1.

The stock cylinder liners cannot tolerate a 6mm bore increase, so Yoshima machines out the cylinder block and installs oversize cast iron liners with a 2.5mm wall thickness. Stock liner wall thickness is 3.75mm.

The rest of the displacement comes from a stroke increased from 62mm to 69mm by installing a CB900 crankshaft. Compared to the stock CB750’s 21.1-lb. crank, the standard CB900 crankshaft weighs 26.5 lb. and the counterweights are larger and shaped differently. Where the CB750’s counterweights taper from 13mm at their thickest down to 9mm. the CB900’s counterweights are not as cut down on the sides and have a less pronounced taper, going from a maximum thickness of 21mm down to 13mm. Yoshima polishes the crankshaft to reduce oil friction in the crankcase. He also chamfers the oil delivery holes on the crank journals to increase the oil supply to the bearings.

To make sure that the plain bearings get enough oil even at the 10,300 rpm redline, Yoshima modifies the oil pump by shimming up the pressure relief spring and by increasing pump output volume with a thicker pump rotor. The shimmed relief spring and the larger rotor increase oil pressure (at operating temperatures) to about 90 psi.

Lubrication is especially critical in the case of the connecting rod bearings, which rely on oil for both lubrication and cooling.

Yoshima has found that the answer to adequate con rod bearing life is to hold bearing surface clearance close to the service minimum of 0.021mm to 0.025mm and to increase bearing side clearance from the usual stock 0.05mm to near the service limit of 0.021mm. or even past the service limit to 0.025mm. In combination with the oil pump modification and the journal oil hole chamfering, the bearing clearance changes increase the flow of cooling oil through the connecting rod bearings, heading off any problems or failure caused by gauling or seizure. Yoshima swears by Ams/Oil 10w-40 synthetic motor oil, and says that experience with his high-revving CB400F engines has shown that the Ams/Oil is best for preventing bearing problems.

All bearings are standard CB900F Keimet F770 material, which is designed for high-output engines and which works just fine in Yoshima’s engine.

A CB900 Hy-Vo primary chain, (which is slightly longer than the CB750 primary chain), must be used with the CB900 crankshaft. The standard 750 jackshaft is retained, but the primary ratio changes from 1.166:1 to 1:1 because both the sprocket on the 900 crankshaft and the sprocket on the 750 jackshaft are the same size, with 28 teeth each. (The 750 crank has a 24-tooth primary gear.)

Connecting rods are always a weak point when pumping lots of extra horsepower into a plain-bearing motorcycle engine, and this one is noMiflferent. Yoshima replaces the CB900F's standard steel rods (which weigh 376 grams compared to the CB750’s 363g rods) with 4130 chromemoly connecting rods built by Carillo to Yoshima's blueprints. Yoshima sells the indestructable Carillo rods, which weigh 339g, for $80 each—which is a lot less expensive than buying new crankcases band-sawed by a broken stock rod.

The Carillo rods are identical to the standard CB900F rods in center-to-center length, measuring 1 17.2mm. But that’s longer than the standard CB750F's rod length of 114.5mm measured center-tocenter. To compensate for the extra stroke, the combustion chamber must be located farther away from the crankcases. Since AMA Superbike Production rules mandate the use of standard cylinder castings, Yoshima couldn’t bolt on a CB900 cylinder. Instead, he machined a half-inch thick aluminum plate to fit between the crankcases and the cylinder base. Yoshima countersunk the head an equal amount> around the cylinder stud holes so that the standard cylinder studs and nuts could be used.

The key to horsepower lies in the cylinder head, and like many tuners. Yoshima is reluctant to discuss his methodology in detail. He will, however, talk about the basic changes and results.

According to Yoshima. the stock cylinder head design is pretty good as it comes from the factory, but he slightly modifies the combustion chamber shape and smooths out the contours of the casting. Yoshima believes in polishing his cylinder heads and says that his work increases head flow' on his flow bench—measured at 9.5mm of valve lift—from 82 cubic feet per minute (cfm) to 95 cfm in the intake tract and from 73 cfm to 82 cfm in the exhaust tract.

Valves are lightened and polished Stockers, 25mm intake and 22mm exhaust, w ith four valves per cylinder. Valve guides are stock. S&W racing CB750 valve springs were too short and had to be shimmed 5mm. Yoshima hardwelds the standard camshafts and regrinds them. Intake cam timing opens the valves at 20° BTDC and closes them 50° ABDC. measured at lmm lift, for a duration of 250°. Exhaust cam timing opens the valves at 50° BBDC and closes them 20° ATDC, again with lmm lift as the starting and ending point of the measurement, for a duration of 250°. Intake valve lift is 8.7mm, exhaust valve lift 8.3mm.

For comparison, the stock CB750F intake cam opens the valves 5° BTDC and closes them at 35° ABDC, w hile the stock exhaust cam opens the valves at 35° BBDC and closes them at 5° ATDC. all measured at lmm lift, for 220° duration for both intake and exhaust. The stock intake camshaft has 7.5mm of lift, and the stock exhaust cam has 8.0mm lift. Valve clearance is set at 0.006 in.

Yoshima also ground a more radical set of camshafts, the intake opening 30° BTDC and closing 60° ABDC, the exhaust opening 60° BBDC and closing 30° ATDC for durations of 270° with measurements taken from and to lmm lift. Lift on the wilder camshafts is 9.8mm intake and 8.5mm exhaust. With those cams in place. Yoshima's bike churned out 135 bhp on his dyno, but problems developed with the valve cups.

Valve lash adjustment shims ride on top of the stock valve cups, but radical, highlift camshafts can kick adjustment shims out of place—and through the cylinder head casting—at high rpm. While the stock cups and shims work fine with the milder 20/50, 50/20 camshaft, Yoshima had to come up with a different set-up for his 30/ 60. 60/30 grind.

With no time to manufacture racingstyle valve cups (which have the adjustment shim located underneath, between the cup and the valve stem tip), Yoshima tried to convert the stock cups. He ground ofif the shim-retaining lip and installed a piece of shaped high-temperature silicone rubber underneath each cup to hold a small adjustment shim in place.

Yoshima used racing kit shims originally made for an 800cc, dohc, water-cooled Honda car engine. The tiny shims weigh about (depending upon thickness) 2.5 grams, compared to about lOg for a stock CB750F shim, I5g for a stock Kawasaki KZ1000, and 4g for a Kawasaki KZ650 (which has shim-underneath valve buckets). The valve cup itself weighed 30g after modification, compared to a Stocker’s 45g.

Because a hardened shim rides atop the stock buckets in standard application, the cup itself isn't heat treated. So when the bucket lip was ground off and the bottom of the shim-holding well became the surface bearing against the camshaft lobe, excessive wear resulted. Yoshima retreated to the 20/50. 50/20 camshafts and the stock buckets and shims, and couldn't get his modified buckets heat treated in time for this article.

The Hy-Vo cam chain running from the crankshaft to the exhaust cam is a CB900 part, and is longer than the CB750 cam chain. The second cam chain, which runs from the exhaust cam to the intake cam, is a stock 750 part.

The stock Honda transistorized, inductive ignition system is used, with the timing advanced 2.5° from stock, to 33.5° BTDC at engine speeds over 3000 rpm. Accel copper-core, silicone-rubber-insu la ted plug w ires are used with NGK D12E spark plugs.

Yoshima’s hand-bent exhaust system weighs 12.5 lb. compared to the stock pipe's 29.5 lb. Head pipe o.d. is 41mm with 38mm inside diameter. The Stocker’s double-wall (to prevent blueing of the chrome) exhaust head pipes have a 38mm o.d. and a 22mm i.d. Yoshima’s head pipes are all equal length, 27.5 in. long. The tail section is 30.7 in. long, including a 10.6-in. megaphone tapering from 2.8 in. o.d. to 4.7 in. o.d. at the end. A 3.0-in. o.d. perforated tube baffle is wrapped with fiberglass and brazed into the megaphone.

The carburetors are 31mm Keihin CR racing carbs fitted with 2-in. velocity stacks. As tested, the carbs had 118 main jets, #200 air jets, #CZ jet needles with the clip located in the 4th position from top, #3 throttle slides, #60 slow jet and the air screw llA turns off the seat. Float level was set at 22.5mm.

Power delivery is close to stock. The clutch is standard except for stronger springs with an additional 10 lb. rating, up from 25 to 35 lb. The transmission is stock, but Yoshima ground all the teeth off the anti-lash auxiliary gear located on the end of the jackshaft. That gear was designed to reduce lash noise between the jackshaft ^and clutch basket, running in place with the jackshaft output gear, but having one less tooth. Since gear noise isn’t a concern to Yoshima, he removed the teeth to reduce friction.

On Yoshima’s dyno, his engine makes 130 bhp at 10,000 rpm, and 78.8 ft. lb. of torque at 8,000 rpm. It’s hard to judge power output from figures given by engine tuners, because like prices and college grades, those figures seem increasingly affected by inflation. At the dragstrip, Yoshima’s bike turned a best of 10.94 sec. at 126.22 mph, running a road racing slick and no wheelie bar. Granted, the rider had a very difficult time coming off the line because the bike wanted to flip over backwards whenever given more than half throttle in first gear. But terminal speeds are not much affected by the starting launch. (The optimum E.T. for a 126 mph terminal speed is about 10.80 sec.).

” Judging by the bike’s full-tank wet weight of 474 lb., the rider weight of 140 lb. and the quarter-mile terminal speed of 126 mph, the engine makes about 120 bhp. The 448-lb. (full tank) Yoshimura R&D of America GS1000 Superbike we tested in May, 1979 turned 10.66 sec. at 132.74 mph, about right for the 133 horsepower claimed by Yoshimura R&D. Clearly, >Yoshima’s bike is down on power at this point. But it must be remembered that the Yoshimuras have been working on and developing their Suzuki Superbike for two years now.

Considering that Yoshima had only boxes of parts and a disassembled motorcycle lying on his shop floor two weeks before we rode his bike, he’s definitely got a good starting point. With the 1979 road racing season over, Yoshima has all winter to work on his engine before Daytona 1980.

More important, he’s got big-bore parts /or high-performance Streeters. Even with the CR Keihin carbs, which are notorious for killing low-and-middle-range power, the bike pulled from 3000 rpm, accelerated hard above 5000 rpm and gained rpm violently from 6000 rpm to the 10,300 rpm redline. With a set of 29mm Mikuni ^smoothbores, the mid-range and low-end would be dramatically better, and Yoshima’s engine would make a very strong, wheelie-prone lOOOcc street bike.

Just the thing for the man who thinks “There’s no such thing as too much power ...”

Ontario Moto Tech Corp. 6850 Vineland Ave., Unit 16 N. Hollywood, Calif. 91605 (213) 766-7101

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsUp Front

November 1979 By Allan Girdler -

Letters

LettersLetters

November 1979 -

Departments

DepartmentsCycle World Roundup

November 1979 -

Competition

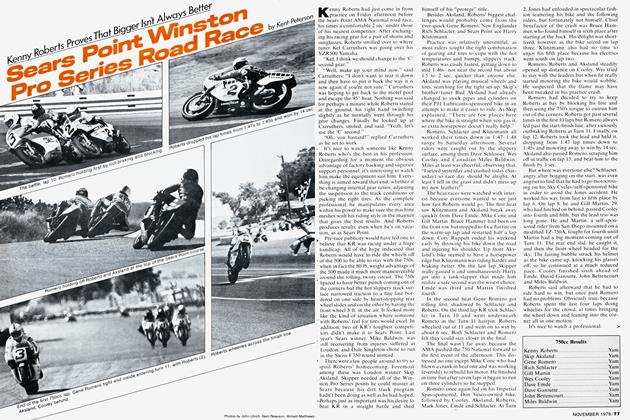

CompetitionSears Point Winston Pro Series Road Race

November 1979 By Kent Peterson -

Competition

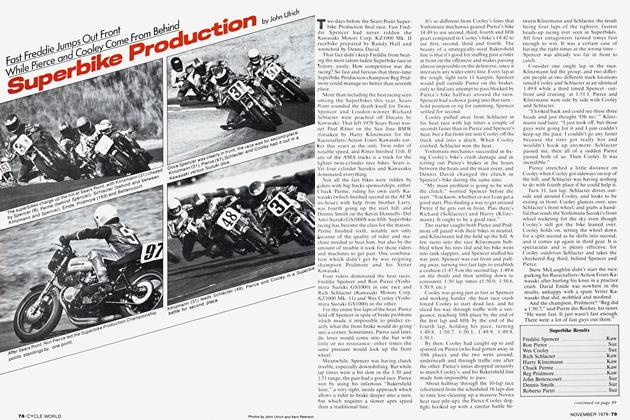

CompetitionSuperbike Production

November 1979 -

Competition

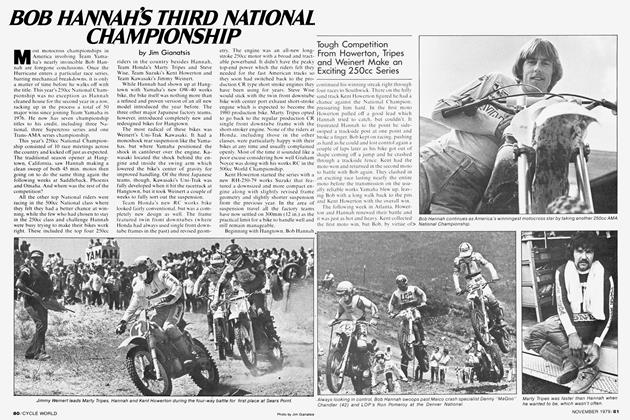

CompetitionBob Hannah's Third National Championship

November 1979 By Jim Gianatsis