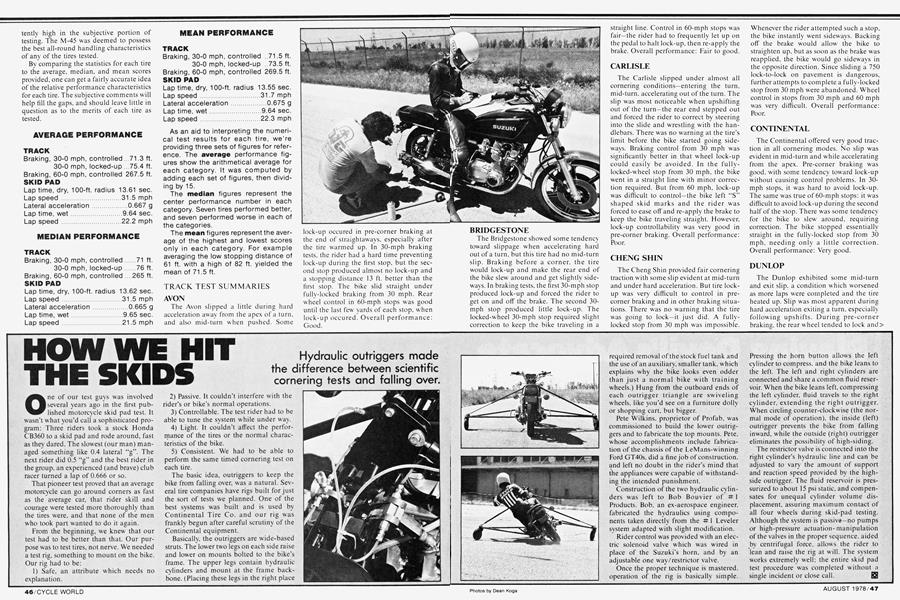

HOW WE HIT THE SKIDS

Hydraulic outriggers made the difference between scientific cornering tests and falling over.

One of our test guys was involved several years ago in the first published motorcycle skid pad test. It wasn’t what you’d call a sophisticated program: Three riders took a stock Honda CB360 to a skid pad and rode around, fast as they dared. The slowest (our man) managed something like 0.4 lateral “g”. The next rider did 0.5 “g” and the best rider in the group, an experienced (and brave) club racer turned a lap of 0.666 or so.

That pioneer test proved that an average motorcycle can go around corners as fast as the average car, that rider skill and courage were tested more thoroughly than the tires were, and that none of the men who took part wanted to do it again.

From the beginning, we knew that our test had to be better than that. Our purpose was to test tires, not nerve. We needed a test rig, something to mount on the bike. Our rig had to be:

1) Safe, an attribute which needs no explanation.

2) Passive. It couldn’t interfere with the rider’s or bike’s normal operations.

3) Controllable. The test rider had to be able to tune the system while under way.

4) Light. It couldn’t affect the performance of the tires or the normal characteristics of the bike.

5) Consistent. We had to be able to perform the same timed cornering test on each tire.

The basic idea, outriggers to keep the bike from failing over, was a natural. Several tire companies have rigs built for just the sort of tests we planned. One of the best systems w'as built and is used by Continental Tire Co. and our rig was frankly begun after careful scrutiny of the Continental equipment.

Basically, the outriggers are wide-based struts. The lower two legs on each side raise and lower on mounts bolted to the bike’s frame. The upper legs contain hydraulic cylinders and mount at the frame backbone. (Placing these legs in the right place required removal of the stock fuel tank and the use of an auxiliary, smaller tank, which explains why the bike looks even odder than just a normal bike with training wheels.) Hung from the outboard ends of each outrigger triangle are swiveling wheels, like you’d see on a furniture dolly or shopping cart, but bigger.

Pete Wilkins, proprietor of Profab, was commissioned to build the lower outriggers and to fabricate the top mounts. Pete, whose accomplishments include fabrication of the chassis of the LeMans-winning Ford GT40s, did a fine job of construction, and left no doubt in the rider's mind that the appliances were capable of withstanding the intended punishment.

Construction of the two hydraulic cylinders was left to Bob Bouvier of # 1 Products. Bob. an ex-aerospace engineer, fabricated the hydraulics using components taken directly from the # 1 Leveler system adapted wdth slight modification.

Rider control was provided wdth an electric solenoid valve which was wired in place of the Suzuki’s horn, and by an adjustable one way/restrictor valve.

Once the proper technique is mastered, operation of the rig is basically simple.

Pressing the horn button allows the left cylinder to compress, and the bike leans to the left. The left and right cylinders are connected and share a common fluid reservoir. When the bike leans left, compressing the left cylinder, fluid travels to the right cylinder, extending the right outrigger. When circling counter-clockwdse (the normal mode of operation), the inside (left) outrigger prevents the bike from falling inward, w'hile the outside (right) outrigger eliminates the possibility of high-siding.

The restrictor valve is connected into the right cylinder’s hydraulic line and can be adjusted to vary the amount of support and reaction speed provided by the highside outrigger. The fluid reservoir is pressurized to about 15 psi static, and compensates for unequal cylinder volume displacement, assuring maximum contact of all four wheels during skid-pad testing. Although the system is passive—no pumps or high-pressure actuation-manipulation of the valves in the proper sequence, aided by centrifugal force, allows the rider to lean and raise the rig at will. The system works extremely well; the entire skid pad test procedure was completed without a single incident or close call. E9