SERVICE

by Len Vucci

We welcome your technical questions and comments, and will publish those we think are of interest to our readers. Because of the volume of mail received, we cannot return any personal replies. Please limit your “Service” letters to technical subjects only, and keep them as brief as possible. Send them to: “Service, ” CYCLE WORLD. 1499 Monrovia Ave., Newport Beach, Calif. 92663.

NORTON LIGHTS

I own a 1974 Norton Commando. This spring it will need a new battery, and I bought a quartz-halogen headlamp to install at the same time. My question is, would it be advantageous to buy a heavier duty battery, or make any other voltage alterations such as relays, etc. before I hook up the lamp? The stock NortonVilliers battery is rated at 8 amp/hours. Your help would be greatly appreciated because 1 don't want to fry my quartz lamp or end up with a $5 beam from a $25 flashlight.

Frank Gagliano

Ocean. N.J.

Since the current required to power an H4/QH headlight is not appreciably more than that required for the sealed beam, the stock system should be entirely adequate. More important than a heavier battery, though, would be a thorough inspection of the bike's wiring. Check and clean the electrical connectors of the charging and lighting systems; a poor connection can

reduce the charge to the battery, reduce the power available to the light, or both.

Although batteries do fail, it's often the charging system which is really at fault. So, when you install the bright light, give the charging system a quick check: Attach a voltmeter to the battery, and turn the lights on. Voltage will probably be 11-12. Start the engine and increase rpm to mid-range. If the meter doesn't indicate about 13.5-14 volts, there could be a problem. Have a competent mechanic have a look if, by the mentioned connection-cleaning, YOU can't fix it.

For those owning street bikes which lack the power for a QH headlight, look for an upcoming article in CW to provide a boost.

HONDA BRAKES & VALVES

I purchased a new Honda CB550F in August. 1975 and have since clocked 32.000 miles, the majority of which is a daily 66-mile freeway commute. The bike has been virtually maintenance free and

very enjoyable except for two things that really annoy me.

When riding in the rain, the front disc has zero stopping power; I have to rely on the rear drum. It seems the disc pucks are planing on the water-covered disc and do not make contact. I want to drill the disc to eliminate this problem, and would like to know what things I should be careful of.

Secondly, I have been unable to keep the adjustment for the intake valves from going sour after less than 1000 miles. The exhaust valves have retained their adjustments for over 25.000 miles but # 1 and #2 intakes loosen in less than 1000 miles. #3 in less than 4000. and #4 seems normal, being adjusted every 8000. If I rev the engine past 6000. #1 and #2 loosen immediately. I’ve replaced the adjusting screws and lock nuts, and torqued them per Honda specs. I’ve talked with other 550 owners and they too have the problem. I would appreciate any recommendations or comments you might have.

I. like others, have come to rely on your> magazine for accurate and up-to-date information; you provide an invaluable service.

R. C. Derr Pittsburg, Calif.

Lately, bikes from several manufacturers have been delivered with relieved disc brake pucks. By cutting shallow grooves in the puck surface, some of the initial hydroplaning action and braking delay can be eliminated. Grooved pucks are not available for your 550F, but you may wish to perform the modification to the stock pads before you spring for disc drilling.

Using a fine-toothed hacksaw blade, carefully cut two slots in the puck at right angles, forming an X with the intersection at the puck's center. If you have access to a vertical mill, a couple of .060-in. passes will result in a neater job.

The slots should be about 2A of the way into the puck material, stopping at the manufacturer's indicated wear line.

If the results from this operation are not, in your opinion, sufficient, drilling of the disc should then be performed. Ventilation holes should be no larger than about ¡/t in. in diameter, and should be lightly chamfered to eliminate sharp edges and accelerated puck wear. Just how many holes in what pattern is subject to debate; queries of several sources netted as many answers. As this operation is best left to experienced machinists, seek out a local shop that performs such a mod, and get an opinion. Or, check out a new BM W or Kawasaki Zl-R, and copy one of those patterns.

The valve clearance problem you describe is most likely caused by the rocker arm shaft spinning in the aluminum cover casting. This results in enough wear that clearances become excessive at a swift rate, and ultimately result in uneven wear of rocker arms and valve tips.

If the wear is severe enough—have it checked by a competent mechanic—the casting and shaft should be replaced. Honda makes a replacement casting which positively locates a newer shaft with a threaded pin.

If yours is still serviceable, you may tighten up the shaft in several ways. Using a aluminum saddles where they contact the shaft, then tap the shaft into place. The forcedfit would grip the shaft more securely. Unfortunately, the shaft might he able to spin even after this mod.

A better way would be to use an adhesive, such as the type of Loctite made for the installation of sleeves and bushings. This would virtually guarantee a non-slip fit, but also guarantee an extremely hard disassembly if it ever becomes necessary.

If once more, you have access to a machine shop, you could drill and tap the cover for a set screw, which should tighten against a fiat filed on the shaft. Not enough room here for a detailed machine operation, so you 'll have to be left on your own for the last fix.

TRIUMPH FLATHEAD

I have enjoyed your magazine for several years now, and in that time it’s proven very helpful to me. I hope you can once again be of assistance.

I have been a devoted Triumph enthusiast since I got out of the Honda Bog with my first 650. I now own three of the machines, a 1971 TR6R. a 1959 T120 and mv latest acquisition, a 500 SV Twin.

It’s this last bike which is causing me problems. Both Triumph books I own. Clymer Triumph 1963-1974 and Haynes Triumph 1947-1962, make no mention of a flathead Triumph, which mine is. Nor is the Solex carburetor mentioned.

The bike was originally an Army surplus police bike, model #500 SV Twin, engine #TRW 26181 NA. The carburetor mentioned is a Solex. WH2. LJ56.

Any information you can dig up would be greatly appreciated, or if you could, give me any tips as to where I can get information/parts in the form of Triumph clubs, dealers, etc. in my area. I am originally from California and don't yet know what West Virginia has to offer.

James D. McNeal General Delivery Craigsville, W. Va. 26205

We're printing your complete address in hopes that someone in your area can lend a hand in providing information and necessary parts. Our March issue contains a listing of club addresses you might be interested in, and the “British Spoken Here" article in our December 1976 issue might be helpful also.

SQUEAL HEAL UPDATE

EMP, the commercial anti-squeal compound for disc-brake pads (“Rebuild Your Brakes," CYCLE WORLD, January, 1978), is now widely available in small continued from page 134 plastic squeeze-packets, for about$1.50-$2. Enough EMP is contained for one twoaxled vehicle (car) or two dual-disc bikes.

continued on page 138

LEAKING KAW

Boy, do I need help! I own a 1970 Kawasaki 500 Mach III. Everytime I put the bike on its side stand, gas pours from the breather hole in the bottom of the float bowl of the middle carb. Normally this would either be caused by incorrect float level or a worn float valve or valve seat. I have checked both of these problems and the float level and valve are perfect.

My mechanic says the leakage is normal. Naturally I laughed in his face. Who could actually believe that a 3 ft. puddle of gas on the floor is normal when the bike’s never done it before?

Joe Crosbie Wainesboro, Miss.

Assuming the brass breather tube inside the float bowl has not been damaged in some strange way, the problem has to be caused by an overly high fuel level. The first recommendation would be to check the items you’ve already mentioned. If the float valve assembly and adjustment are indeed correct, the problem could be caused by a leaking float. This would allow gas to enter, decreasing its buoyancy, and increasing the carb’s fuel level. If the brass float sloshes when you shake it, you’ve found the problem. Replacement is normally in order, but, if you’re a whiz at soldering (common lead-tin type), you can do it yourself. Just make sure you’ve evacuated the float before you seal it, then check it by immersion in a tub of water, and watch for tiny bubbles.

JET OR MISSILE?

Am I correct in assuming that the best main jet is that one which produces the highest speed?

Larry Koch Los Alamos, N.M.

Yes. And no.

There are many considerations which will determine optimum jetting. For a twostroke, these requirements are especially stringent.

With an overly rich (large) jet, performance and fuel economy will suffer.

A lean jet might produce more power and higher bike speeds—but will increase combustion chamber temperatures. Adverse effects range from detonation (pinging) to seizures and holed pistons.

Ask a drag racer and a Baja racer and you’ll get at least two different answers. A basic rule might read the best is the one that produces the fastest speeds for the entire duration of the ride. For a more specific explanation, read the article on carburetion tuning in our January, 1977 issue. SI

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontCarte Blanche

June 1978 By Allan Girdler -

Letters

LettersLetters

June 1978 -

Roundup

RoundupRoundup

June 1978 By Tim Barela -

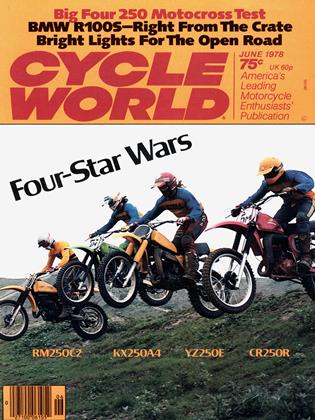

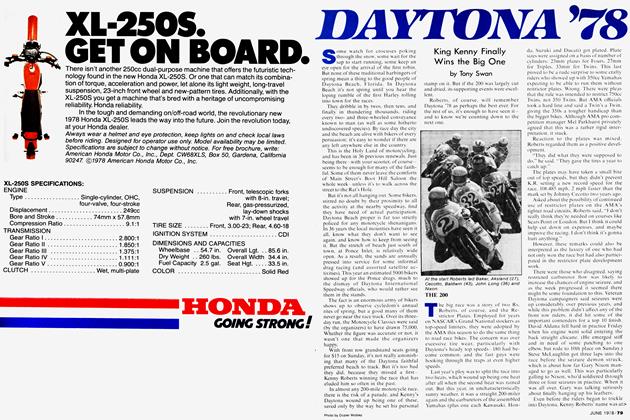

Competition

CompetitionDaytona '78

June 1978 By Allan Girdler, Tony Swan -

Features

FeaturesThe Folks At the End of the Trail

June 1978 By Bob Hicks -

Competition

CompetitionAn Incomplete Guide To Special Events

June 1978