TWISTER INLINE THROTTLE

EVALUATIONS

For many years off-road riders have cussed and discussed standard mo torcycle throttles. Three nagging problems continually tormented competition riders. Most annoying, the loop of cable as it exits the throttle at a 90 degree angle and makes a gradual u-turn back toward the carburetor. This loop of cable is great for snagging other bars and has a magnetism for tree limbs. This attack on the cable normally turns the bars and opens the carburetor, causing a sudden burst of speed. The experience is terrifying and usually results in a crash.

The second problem is cable life. Most throttles require the cable to bend as it is pulled. This continual bending causes premature cable failure.

The third fault also causes short cable life. Throttles are designed to be as universally adaptable as possible. Thus, the fullon internal stop is usually positioned so it will allow a large bore carb (38-40mm) to open fully. When a unit that has been designed to open a 40mm carb is installed on a bike with a 26-28mm carb, the throttle won’t even be close to the limiter stop at full throttle. This combination causes the cable to stretch and break.

Funny that new designs have been so slow appearing. The Gunnar Gasser was introduced about a year ago and effectively eliminates the cable loop problem, but the other two faults still exist.

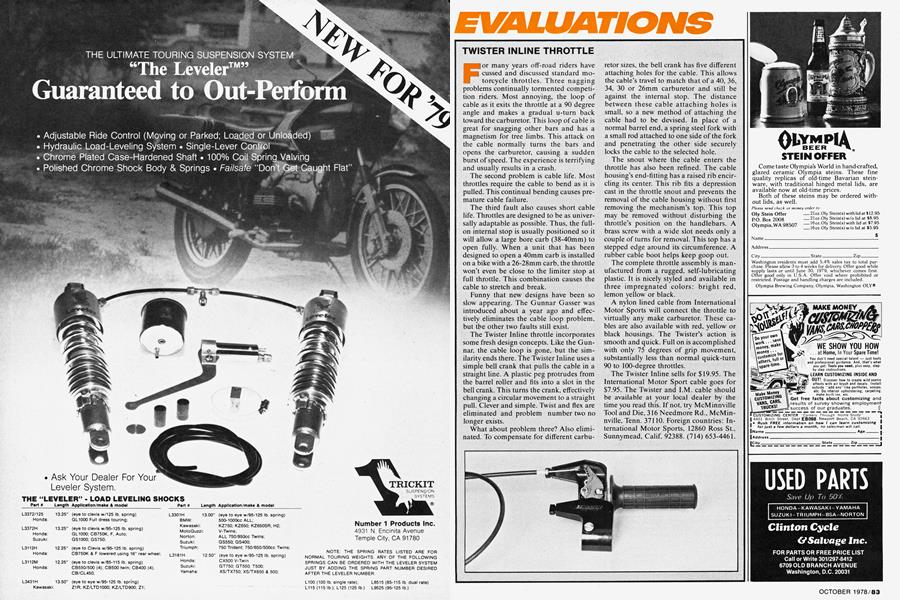

The Twister Inline throttle incorporates some fresh design concepts. Like the Gunnar, the cable loop is gone, but the similarity ends there. The Twister Inline uses a simple bell crank that pulls the cable in a straight line. A plastic peg protrudes from the barrel roller and fits into a slot in the bell crank. This turns the crank, effectively changing a circular movement to a straight pull. Clever and simple. Twist and flex are eliminated and problem number two no longer exists.

What about problem three? Also eliminated. To compensate for different carburetor sizes, the bell crank has five different attaching holes for the cable. This allows the cable’s travel to match that of a 40, 36, 34, 30 or 26mm carburetor and still be against the internal stop. The distance between these cable attaching holes is small, so a new method of attaching the cable had to be devised. In place of a normal barrel end, a spring steel fork with a small rod attached to one side of the fork and penetrating the other side securely locks the cable to the selected hole,

The snout where the cable enters the throttle has also been refined. The cable housing’s end-fitting has a raised rib encircling its center. This rib fits a depression cast in the throttle snout and prevents the removal of the cable housing without first removing the mechanism’s top. This top may be removed without disturbing the throttle’s position on the handlebars. A brass screw with a wide slot needs only a couple of turns for removal. This top has a stepped edge around its circumference. A rubber cable boot helps keep goop out.

The complete throttle assembly is manufactured from a rugged, self-lubricating plastic. It is nicely styled and available in three impregnated colors: bright red, lemon yellow or black,

A nylon lined cable from International Motor Sports will connect the throttle to virtually any make carburetor. These cables are also available with red, yellow or black housings. The Twister’s action is smooth and quick. Full on is accomplished with only 75 degrees of grip movement, substantially less than normal quick-turn 90 to 100-degree throttles,

The Twister Inline sells for $19.95. The International Motor Sport cable goes for $7.95. The Twister and LM. cable should be available at your local dealer by the time you read this. If not, try McMinnville Tool and Die, 316 Needmore Rd., McMinnville, Tenn. 37110. Foreign countries: International Motor Sports, 12860 Ross St., Sunnymead, Calif. 92388. (714) 653-4461.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontYou Can't Take the Harley Out of the Boy

October 1978 By Allan Girdler -

Departments

DepartmentsBook News

October 1978 By A.G., Chuck Johnston, Michael M. Griffin -

Letters

LettersLetters

October 1978 -

Departments

DepartmentsRoundup

October 1978 -

Short Strokes

October 1978 By Tim Barela -

Technical

TechnicalYamaha It250/400 Steering Fix

October 1978 By Len Vucci