THE SERVICE DEPT

Len Vucci

If you have a question or comment of a technical nature, send it to us. We’ll attempt to answer as many letters as possible and we’ll publish those which we think are of interest to the majority of our readers. We’ll also print some helpful hints and how-to’s reflecting frequently asked questions. Technical correspondence should be sent to: Service Department, CYCLE WORLD, 1499 Monrovia Ave., Newport Beach, Calif. 92663.

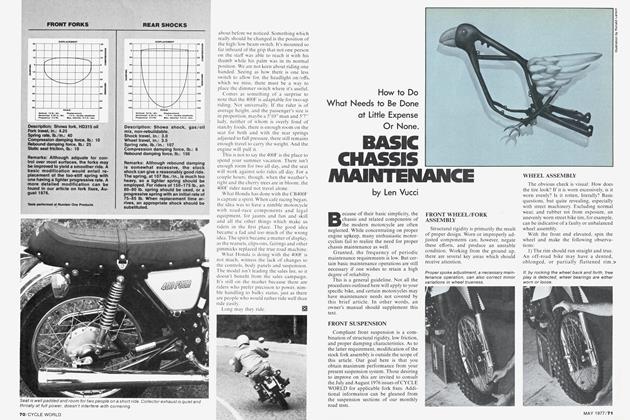

SUSPENSION

I have a question about improving the handling of my BMW, a late 1976 R75/6. The dealer can’t make it run straight down the road. I could take my hands off the bars of my 1971 R60/5 at any speed and it would run straight, but my new one dives off course to the right. I’m almost afraid to find out, but what’s up?

Do you think dual-rate front fork springs would allow a soft ride yet reduce nose-dive during hard braking? What about changing fork oil?

Noel Squitieri Pittsburgh, Penn.

Assuming the fork components are properly aligned, your stability problem must stem from either a frame or swing arm misalignment. Although less common on drive shaft bikes, the resulting improper wheel tracking could manifest itself in such a manner.

Late BMWs are equipped with 20/36 progressive fork springs. These should yield an acceptable comfort/control balance by using heavier weight fork oil. If you feel the brake dive still excessive, a slightly higher rate spring (approx. 24-40) should then be tried.

I have a 1972 Honda CB750K2. The fork springs on this machine have given up. The article on fork fixes in your August 1976 issue suggests use of the 28/38 lb. progressive spring made by S&W as a replacement.

Does mounting a fairing require use of heavier fork springs? If so, what spring should I use for my machine, which is equipped with a Vetter Windjammer?

Alden O. Kontak Perrysburg, Ohio

The additional mass of a fairing certainly affects suspension characteristics, but can usually be compensated by an increase in preload. Run the S& W 28/38 progressive springs, with an additional inch of preload as a starting point. If this is unsatisfactory, proper ride attitude can be obtained by varying the spring preload.

INTERMITTENT RD350

Can you help me solve a baffling problem? I own a 1973 Yamaha RD350 which runs okay until it heats up. Then the left cylinder quits running, and the battery goes dead—the lights won’t burn and the horn won’t blow. After the bike cools off, both cylinders run perfectly. But after heating up it does the same thing again.

Jerry W. Robbins Marston, N.C.

Since all of the electrically dependent components cease to function simultaneously, the cause must be a deficit in supply voltage: a dead battery. The charging system should maintain proper voltage, but if defective, can allow battery voltage to drop off, causing the symptoms you describe. There is an easy check: Run the bike until it goes dead, then jump your bike's battery with another, or with a 12-volt trickle charger. Normal operation should resume. Assuming the bike's original battery is still operational, the problem must lie in either the regulator or rectifier.

continued on page 110

continued from page 106

Take the bike back to your dealer and run it until the problem occurs. Have him try a new rectifier, then a new regulator on the bike. This should eliminate the problem.

TRIPLE TROUBLE

I am the proud owner of a Yamaha XS750D. Considering my big bike experience dating back to a new shaft-drive Sunbeam in 1948, and various bikes in between, this Yammy has got to be the finest bike on the road, on a par with the BMW. Performance and reliability are excellent for commuting and long-distance touring, and service is generally good.

Two head-scratchers have presented themselves in the first 2500 miles of riding:

1. Timing marks using strobe are deadon for cylinders 1 and 3, but oscillate 3-4 degrees either side of the mark on number 2. Point assembles were swapped between 2 and 3, but the problem remained on number 2. Wicks were oiled and all point assemblies tightened. Dwell is not specified, but appears to be approximately 58 degrees all around.

2. This motor has a mild knocking in a very light roll-on between 2000 and 2500 rpm. This disappears when the throttle is returned to a steady cruise position, and is not noticeable at any other throttle setting, hot or cold. The sound appears to come from the right cylinder.

All specified service checks have been performed and the local dealer’s mechanic doesn’t have an answer to either problem. Also, the number 3 cylinder fins seem to heat up (becoming too hot to touch) several minutes prior to the number 1 fins. I don’t know if this is indicative of anything or not. All cylinder pressures are at 145 psi, and plugs read out normal for deposits. Carbs have been set and balanced. The knocking does not sound like a valve tick, but I’m stumped.

continued on page 114

continued from page 110

Possibly you have run across these problems on the XS750D. I hope somebody has an idea, because I am concerned about it, as are the other two 750D owners in this area whose bikes are sadly sitting out the last four months of their warranty period in winter storage.

Incidentally, how did Ken Buzzell (February “Service Department”) make a TDC indicator from a DHC-6 glow plug? I have been flying “Twotters” for almost 10 years now, and that’s a new one on me! Those Pratt and Whitney’s are more versatile than one would think. Would it work with a canted plug (750 type)?

Dallas W. Hamlin West Lawn, Pa.

The timing variation certainly does seem to be a stumper, but here's a couple of suggestions: Try switching the number 2 condenser with either of the others, and repeat your test. If this proves futile, switch the primary and secondary wires between the number 2 coil and either number I or number 3. Timing variation should then be reproduced in another cylinder.

The mild knock you describe may be detonation (pinging). This condition may be caused by excessive timing advance, lean carburetion, or poor-quality gasoline.

Since you are having ignition problems, that area should be sorted out first. Then check the carburetion system for leaks. Include the neoprene slide diaphragms. Make sure the slide needles are positioned identically, and the jet sizes are the same.

As to Mr. Buzzel/’s adaptation, that's an Otter story in itself. For canted spark plug configurations, the adapters provided with better commercial dial indicators should work acceptably. IÔ1