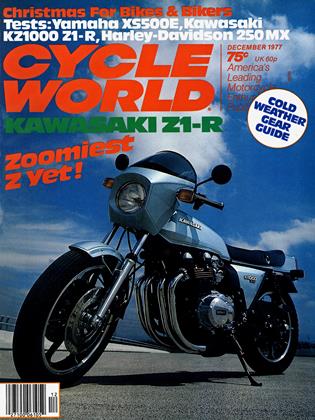

HARLEY-DAVIDSON MX25O

CYCLE WORLD TEST

A Prototype Bike in Production Clothing

Last year HarleyDavidson built 100 special 250cc motocross bikes and offered them to local racers through its large dealer network. They were strange looking creatures having what resembled front forks at the rear in place of conventional shocks. This unconventional form didn't work as well as anticipated and was dropped in favor of a more normal arrangement. This development has been going on for four years at Harley-Davidson R&D. Factory MX riders have furnished input. Development has progressed.

Now a production model is available. Perhaps.

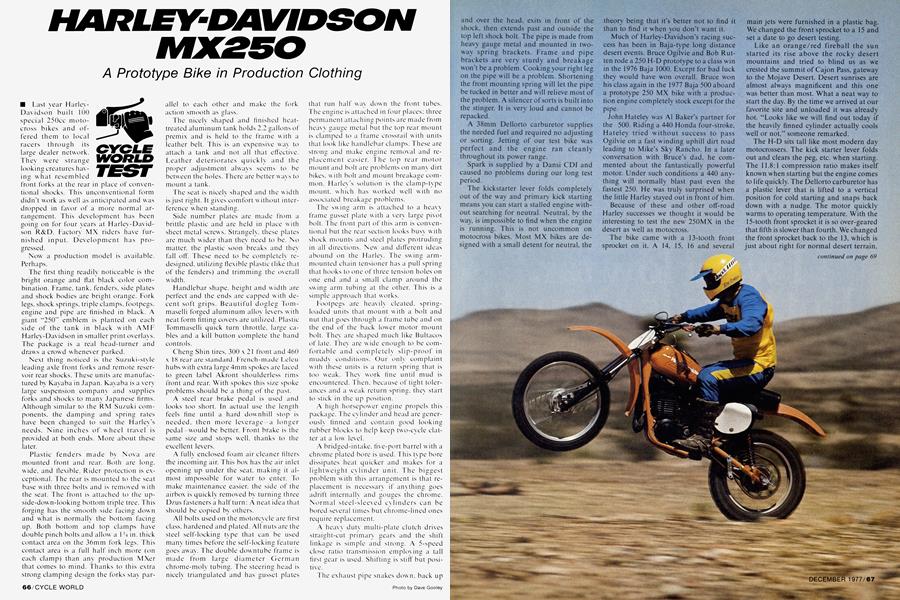

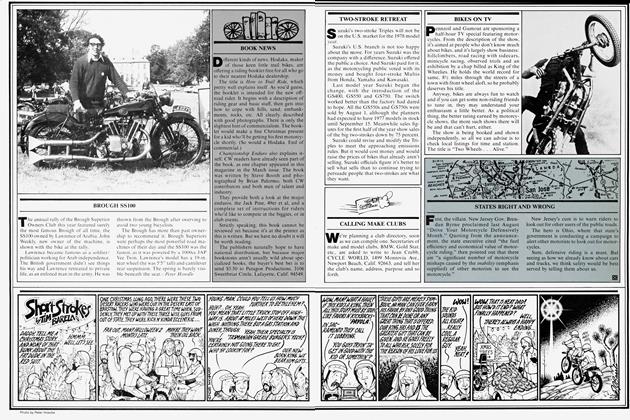

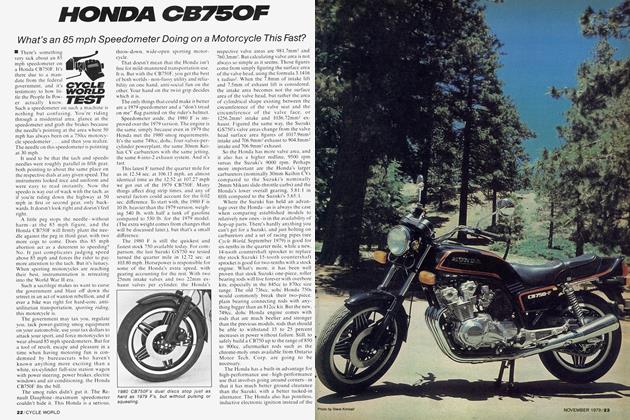

The first thing readily noticeable is the bright orange and fiat black color combination. Frame, tank, fenders, side plates and shock bodies are bright orange. Fork legs, shock springs, triple clamps, footpegs. engine and pipe are finished in black. A giant “250" emblem is planted on each side of the tank in black w ith AM F Harley-Dav idson in smaller print overlays. The package is a real head-turner and draws a crowd whenever parked.

Next thing noticed is the Suzuki-style leading axle front forks and remote reservoir rear shocks. These units are manufactured by Kayaba in Japan. Kayaba is a very large suspension company and supplies forks and shocks to many Japanese firms. Although similar to the RM Suzuki components, the damping and spring rates have been changed to suit the Harley's needs. Nine inches of wheel travel is provided at both ends. More about these later.

Plastic fenders made bv Nova are mounted front and rear. Both are long, wide, and flexible. Rider protection is exceptional. The rear is mounted to the seat base with three bolts and is removed with the seat. The front is attached to the upside-down-looking bottom triple tree. This forging has the smooth side facing down and what is normally the bottom facing

up. Both bottom and top clamps have double pinch bolts and allow a I N in. thick contact area on the 36mm fork legs. This contact area is a full half inch more (on each clamp) than any production MXer that comes to mind. Thanks to this extra strong clamping design the forks stay parallel to each other and make the fork action smooth as glass.

The nicely shaped and finished heattreated aluminum tank holds 2.2 gallons of premix and is held to the frame with a leather belt. This is an expensive way to attach a tank and not all that effective. Leather deteriorates quickly and the proper adjustment always seems to be between the holes. There are better wavs to mount a tank.

The seat is nicely shaped and the w idth is just right. It gives comfort without interference when standing.

Side number plates are made from a brittle plastic and are held in place with sheet metal screws. Strangely, these plates are much w ider than they need to be. No matter, the plastic soon breaks and they fall off. These need to be completely redesigned. utilizing flexible plastic (like that of the fenders) and trimming the overall w idth.

Handlebar shape, height and width are perfect and the ends are capped with decent soft grips. Beautiful dogleg Tommaselli forged aluminum alloy levers with neat form fitting covers are utilized. Plastic Tommaselli quick turn throttle, large cables and a kill button complete the hand controls.

Cheng Shin tires. 300 x 21 front and 460 x 18 rear are standard. French-made Leleu hubs with extra large 4mm spokes are laced to green label Akront shoulderless rims front and rear. With spokes this size spoke problems should be a thing of the past.

A steel rear brake pedal is used and looks too short. In actual use the length feels fine until a hard downhill stop is needed, then more leverage - a longer pedal would be better. Front brake is the same size and stops well, thanks to the excellent levers.

A fully enclosed foam air cleaner filters the incoming air. T his box has the air inlet opening up under the seat, making it almost impossible for water to enter. To make maintenance easier, the side of the airbox is quickly removed by turning three Dzus fasteners a half turn: A neat idea that should be copied by others.

All bolts used on the motorcycle are first class, hardened and plated. All nuts are the steel self-locking type that can be used many times before the self-locking feature goes away. The double downtube frame is made from large diameter German chrome-moly tubing. The steering head is nicely triangulated and has gusset plates that run half wav down the front tubes. The engine is attached in four places: three permanent attaching points are made from heavy gauge metal but the top rear mount is clamped to a frame crossrail with units that look like handlebar clamps. These are strong and make engine removal and replacement easier. The top rear motor mount and bolt are problems on many dirt bikes, with bolt and mount breakage common. Harley’s solution is the clamp-type mount, which has worked well with no associated breakage problems.

The swing arm is attached to a heavy frame gusset plate with a verv large pivot bolt. The front part of this arm is conventional but the rear section looks busy w ith shock mounts and steel plates protruding in all directions. New and different ideas abound on the Harlev. The swing armmounted chain tensioner has a pull spring that hooks to one of three tension holes on one end and a small clamp around the swing arm tubing at the other. This is a simple approach that works.

Footpegs are heavily cheated, springloaded units that mount with a bolt and nut that goes through a frame tube and on the end of the back lower motor mount bolt. They are shaped much like Bultacos of late. They tire wide enough to be comfortable and completely slip-proof in muddv conditions. Our onlv complaint with these units is a return spring that is too weak. They work fine until mud is encountered. Then, because of tight tolerances and a weak return spring, they start to stick in the up position.

A high horsepower engine propels this package. The cylinder and head are generouslv finned and contain good looking rubber blocks to help keep two-cycle clatter at a low level.

A bridged-intake, five-port barrel with a chrome plated bore is used. This tvpe bore dissipates heat quicker and makes for a lightweight cylinder unit. The biggest problem with this arrangement is that replacement is necessary if anything goes adrift internally and gouges the chrome. Normal steel-sleeved cylinders can be bored several times but chrome-lined ones require replacement.

A heavy duty multi-plate clutch drives straight-cut primary gears and the shift linkage is simple and strong. A 5-speed close ratio transmission employing a tall first gear is used. Shifting is stift' but positive.

The exhaust pipe snakes dow n, back up and over the head, exits in front of the shock, then extends past and outside the top left shock bolt. The pipe is made from heavy gauge metal and mounted in twoway spring brackets. Frame and pipe brackets are very sturdy and breakage won’t be a problem. Cooking your right leg on the pipe will be a problem. Shortening the front mounting spring will let the pipe be tucked in better and will relieve most of the problem. A silencer of sorts is built into the stinger. It is very loud and cannot be repacked.

A 38mm Dellorto carburetor supplies the needed fuel and required no adjusting or sorting. Jetting of our test bike was perfect and the engine ran cleanly throughout its power range.

Spark is supplied by a Dansi CDI and caused no problems during our long test period.

The kickstarter lever folds completely out of the way and primary kick starting means you can start a stalled engine without searching for neutral. Neutral, by the way, is impossible to find when the engine is running. This is not uncommon on motocross bikes. Most MX bikes are designed with a small detent for neutral, the theory being that it’s better not to find it than to find it when you don’t want it.

Much of Harley-Davidson’s racing success has been in Baja-type long distance desert events. Bruce Ogilvie and Bob Rutten rode a 250 H-D prototype to a class win in the 1976 Baja 1000. Except for bad luck they would have won overall. Bruce won his class again in the 1977 Baja 500 aboard a prototype 250 MX bike with a production engine completely stock except for the pipe.

John Hateley was AÍ Baker’s partner for the 500. Riding a 440 Honda four-stroke, Hateley tried without success to pass Ogilvie on a fast winding uphill dirt road leading to Mike’s Sky Rancho. In a later conversation with Bruce’s dad, he commented about the fantastically powerful motor. Under such conditions a 440 anything will normally blast past even the fastest 250. He was truly surprised when the little Harley stayed out in front of him.

Because of these and other off-road Harley successes we thought it would be interesting to test the new 250MX in the desert as well as motocross.

The bike came with a 13-tooth front sprocket on it. A 14, 15, 16 and several main jets were furnished in a plastic bag. We changed the front sprocket to a 15 and set a date to go desert testing.

Like an orange/red fireball the sun started its rise above the rocky desert mountains and tried to blind us as we crested the summit of Cajon Pass, gateway to the Mojave Desert. Desert sunrises are almost always magnificent and this one was better than most. What a neat way to start the day. By the time we arrived at our favorite site and unloaded it was already hot. “Looks like we will find out today if the heavily finned cylinder actually cools well or not,” someone remarked.

The H-D sits tall like most modern day motocrossers. The kick starter lever folds out and clears the peg, etc. when starting. The 11.8:1 compression ratio makes itself known when starting but the engine comes to life quickly. The Dellorto carburetor has a plastic lever that is lifted to a vertical position for cold starting and snaps back down with a nudge. The motor quickly warms to operating temperature. With the 15-tooth front sprocket it is so over-geared that fifth is slower than fourth. We changed the front sprocket back to the 13, which is just about right for normal desert terrain, giving it about 70 mph top speed.

continued on page 69

HARLEY-DAVIDSON

$1695

continued from page 67

The motor is very pipey and is much like a 125 with 32 horsepower. It shifts a little stiffly and the clutch, which is needed often with a pipey powerband, is hard to pull. Bar-peg-seat relationship is good and the seat comfortable. Bar height and width feels fine to most people.

The H-D has a 30-degree rake combined with a 58-in. wheelbase making high speed stability excellent. The front wheel can be lofted easily for ditches etc., as long as it is on the pipe. When off the pipe, most of the usable power is lost but it refuses to load up or become flooded with gas. The 250 tracks arrow straight down sand washes and through whoop-dee-dos and sweeping high-speed turns.

It’s hard to slide because of its powerband and is happier if the rider hits a berm or makes a square turn. Directional maneuvers are best performed with the bike in a more upright position much like the style Huskys prefer. With the smallest supplied front sprocket (13-tooth) low gear is still good for about 30 miles per hour: Fine for motocross but a real handful on a rocky hill for anyone but an expert.

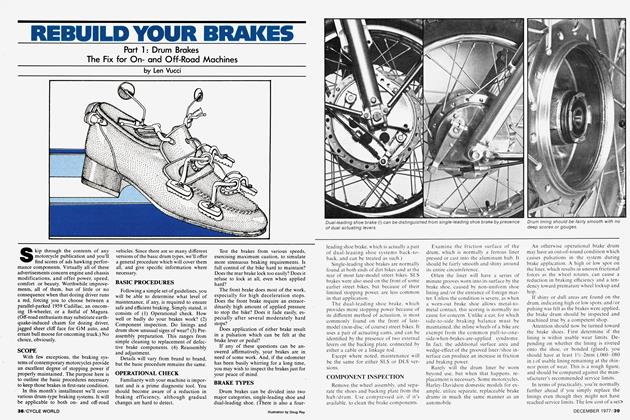

Damping and spring rates are absolutely perfect for desert/cross-country use—soft and comfortable without bottoming often. The actual nine inches of travel front and rear soak up the gullies and ditches and> ripples and small bumps are unnoticed.

The front brake cable uses only one wire guide and bows outward, catching bushes when the forks are working. This was mostly fixed by taping the cable to the bottom fork slider but another cable guide above the existing one is needed.

We ran the bike hard all day in the desert. It didn't overheat or ping and the engine stayed responsive throughout the test. The bike could be made into an excellent cross-country machine by using a bigger gas tank, a pipe designed to broaden the pow'erband. and wide ratio gears for first, second and third.

Next our pro motocrosser raced the bike at a local track after Metzeler tires were installed front and rear. After practice his comments were. “The rear brake isn't strong enough, the front brake is good, suspension is soft front and rear, but it doesn’t wallow or bottom excessively. The engine is pipev. clutch pulls hard and is impossible to fan (which he felt was necessarv to get optimum performance from the engine). The pipe burns my leg in lefthand turns, it’s very quick when it’s on the pipe, gearing is tall, and, oh yea. I'll be able to win on it!”

Famous last words. In the middle of the first lap on a cobby uphill the rear wheel grabbed something and threw him onto the tank belt buckle really hard. After a 15minute recovery period and much concern for his future as a father we decided to quit for the day. Upon inspection one shock felt sticky and it was decided we should run the used ones on Number 1 Products’ shock dyno and compare the curve with a new shock.

H-D's fleet test manager supplied us with a new' set of shocks and springs for the bike and dyno testing.

A day spent riding at Saddleback Park, a demanding MX course, followed. Suspension felt excellent. No bad behavior could be uncovered and the bike stuck to the hard, slippery adobe track like it was

glued. The shock dyno results came back and showed some stickiness was present and some compression damping loss, but nothing to indicate extremely erratic behavior. Evidently the strange action at the first motocross race was a result of track condition or rider error.

One mechanical failure occurred on the first day of testing. After shifting into third nothing happened. The engine raced—we thought we'd missed the gear. A shift to fourth, then fifth—nothing. The drive chain was still on so we removed the clutch side engine cover for inspection. The clutch nut was still tight but the primarydrive gear nut had loosened. This drive gear is on a tapered shaft w'ithout a Woodruff key. Although the nut had a lock tab. it had loosened. After cleaning and applying Loctite. the nut was tightened and the lock tab bent back into place.

The 250 was ridden many times after this repair without further failure. The original spark plug is still in the bike and not one spoke has loosened. HarleyDavidson spent four years developing its first production 250MX. Most of its pieces are first rate. A couple items like the side number plates and overall gearing need refinement. The frame and associated gussets and brackets are robustly constructed and add up to make it a little heavy.

When we first looked at the specifications sheet, we wondered about the price. On the high side. When we looked at the bike, we understood. Not for years have we seen so much hand work. There are countless places on the frame where a human being had to weld and fit and attach. The swing arm is an even better example. It appears to be assembled from a score of pieces. Man hours cost money.

There are other signs. The exhaust pipe could be routed between the back tube and the airbox. then inside the shock bracket. As it is now. the number plate and pipe must come off before the left shock can be changed.

Strictly speaking, the H-D 250MX isn’t a prototype or a works bike. The model is in production.

But we don’t think the 250MX is completely finished. The engine is fine. So is the suspension. The private owner will be required to work extra hard to win. and to maintain the bike. Any rider who isn’t at the head of his class in motocross or the desert better skip this one if he’s looking for a play bike. The Harley must be ridden hard if it’s to be ridden at all.

Harley-Davidson is making a commendable effort. Harley engineers are using good parts, from all over the world. They’re fielding a team, supplying parts, backing their dealers with ads. The 250MX should be considered a racing bike for those who don’t mind adding the final touches themselves.