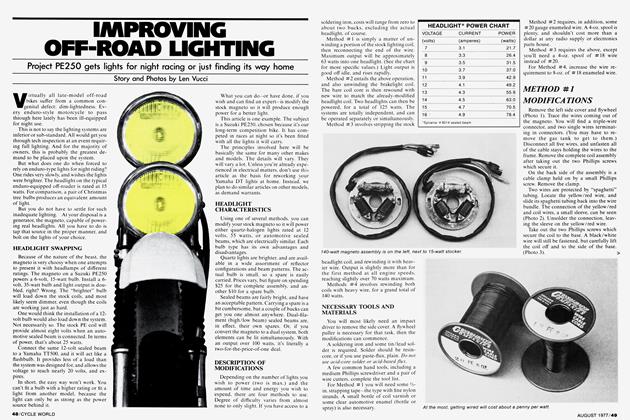

SERVICE

Len Vucci

VESTED INTEREST

This spring, having purchased a Widder Lectric-Vest, I had to buy a bike to go with it. So I bought a 1977 Honda CB750K. The only problem upon combining the two is a noticeable dimming in headlight brightness when the vest is on. Would using a bigger battery cure this?

Also, because of the headlight constantly being burned, I have gone through one headlight in only 1600 miles. Are there any good, bright, automotive-type lights that will fit in the stock shell?

Kevin C. Moorhead Blue Grass, Iowa

We tested the Widder vest for our October 1976 issue, whereupon it was commandeered by an enthusiastic staffer. It has been used on various test bikes, including several Hondas, with no diminished headlight brightness.

Before you attempt a battery swap, check for loose or corroded connections especially at the battery. Have the charging circuit checked out also, as it may not be operating at its maxiumum capacity.

A 7-in. automotive sealed beam, or a quartz-type replacement unit, will fit with

no modifications: We suggest you first consult the vehicle equipment codes in your state to determine the legality of such a conversion.

CHECKING FOR CHARGE

I own a 1969 Honda 750 with 35,000 miles on it. While riding, the screws that secure the alternator stator to the case loosened, and it banged around inside until I could get stopped. After replacing the screws it ran fine, but the battery soon went dead. The engine no longer recharges the battery, which dies about 100 miles after being charged. I have the engine torn down for other repairs, but can you help me on this one? Do you think the problem could be the rectifier?

Dave Swales Daytona Beach, Fla.

While appearing to be in good condition, the stator was probably damaged internally. There is the chance that another component in the system failed during the incident, but its replacement would be of no value if the stator is inoperative.

Using an ohmmeter, you can make the resistance checks of the stator which may reveal the problem.

Locate the rectangular 8-pin connector under the left side cover and unplug it. The female side leads to the alternator. There is a white, a green, and three yellow wires that should be checked.

Arbitrarily calling the yellow wires A, B, and C, measure the resistance from A to B, A to C, and B to C. Each reading should be low—about 0.4 ohm—but not zero. Resistance from the green wire to the white should be about 7 ohms. Resistance reading from any yellow wire to the green or white wire, or the engine case, should be infinity.

If possible, check the reading for your stator against those for a known good one.

Grossly different resistance readings would indicate replacement to be necessary.

BELT DRIVE

I have heard that UniRoyal has developed a toothed rubber belt to be used in place of a chain for a bike’s final drive. Supposedly, it was tried on a HarleyDavidson Sportster, and the bike was much faster on the top end. In light of this alleged improvement, and the hassle presented by a drive chain, the belt drive would be a welcome conversion. Can you shed a little light on the issue?

continued on page 26

continued from page 24

H.S. Dorman Wildomar, Calif.

The only belt drive we can locate is the Karate Belt Drive, distributed by Graveyard Wholesale Specialties, Conshohocken, Pennsylvania. It is a toothed rubber belt drive, but is used for primary (crankshaft to transmission) drive, and not final. It is available for 1974 Harley and Sportster models only.

To our knowledge, no one has successfully used that type of drive as a direct replacement for the chain. Besides the substantially greater load requirements of final drive, there is also the problem of maintaining proper tension for the total range of wheel travel.

Chain drive meets these requirements, and does so with a high efficiency factor. Except for the shaft drives, expect the chain to be the standard means of power transfer for years to come.

VALVE CLATTER

I own a 1975 Honda CJ360T, and in 2000 miles of riding, I’ve had only one problem. After each valve adjustment, one exhaust valve will clatter after about 75 miles of riding. Do you know if others have experienced a similar problem, and can you offer an explanation as to possible cause?

James Whaley Seaford, Del.

Yours is the only letter we’ve received on this specific problem.

In general, increasing valve clearance can be attributed to two causes. The first is a shift in component location because of insufficient tightening of adjustable components. Judging from your letter, this is unlikely. The second cause is wear. An insufficient lubrication supply will promote rapid destruction of hardened surfaces, especially cam lobes and rocker arms. Revving a cold engine before allowing oil pressure to build up is one possible cause of accelerated wear. Faulty surface hardening of cam, rocker arm, or valve stem is another.

On the basis of the information you’ve provided, you should probably have a competent mechanic inspect the valve gear for possible damage.

BURNT VALVE

Last year I bought a 1972 Honda CB350 which ran great for the first few months. Then it became difficult to start and developed a knocking sound. I tested the compression, and the left cylinder read 180 psi while the right read only 120 psi. I tore the engine down, and found the right exhaust valve to be colored differently from the others as if it were overheated. Could this be the cause of its hard starting and low compression problem? If so, what should I do to correct it? If not, what are some possible causes of engine knock?

John Ryder Brooklyn, N.Y.

It sounds as though the valves were adjusted improperly, and there was insufficient clearance on the burnt-looking one. Insufficient clearance will not allow the valve to contact its seat for an interval long enough for cooling between combustion cycles. A n exhaust valve is more easily burned than an intake, as it does not benefit from the cooling action of the incoming air/fuel charge.

Corrective action will, for your bike, most likely require valve and seat replacement by a competent mechanic.

CARB PROBLEMS

I own a 1975 Honda Elsinore with a few modifications. It runs well on top end, but has no power in low and mid-range. Unless the throttle is wide open and the clutch is slipped to get moving, the engine bogs down and dies. Help!

Jeff Heilweg Colorado Springs, Colo.

I have a problem with my Kawasaki 125 enduro. It runs alright until I get on it hard, then it cuts out and loses power. Is my problem in the carburetor or in the ignition?

Paul Rhudy

Kansas City, Kan.

Both of your bikes seem to be suffering from carburetion problems, although there is the chance that the ignition might be at fault. Check for loose or dirty electrical connections, spark plug condition and gap, and then proceed to the carburetor. For the Honda, inspect the idle screw, pilot jet, and float level. These components affect bot tomend mixture. On the Kawasaki carb, we’d bet the needle position is wrong, and/or the main jet is too large. Check your owner’s manual for proper specifications.

A more detailed explanation of carburetor tuning can be found in our January, 1977 issue. But if tweaking the carburetor does not produce desired results, go back and give the ignition system a thorough check.

STIFF WING

I own a 1976 Honda Gold Wing, my second, and would like to improve its stiff ride, especially over pavement joints. I have written several shock manufacturers for information, but have received no answers. None of the dealers seem to have any ideas either. Can you offer any suggestions to improve my GL’s suspension?

Wallace Engel Graceville, Minn.

continued on page 28

continued from page 27

Your complaint is a common one, and is the result of the fork design. A fter very few road miles, there is severe wear on the bottom of the stanchion tubes stemming from inadequate lubrication. Fork oil is squeezed out of the relatively small contact area between stanchion tube and sliders, resulting in metal-to-metal contact. Friction at this point is very high, and cause the forks to bind. When a bump large enough to overcome this stickness is encountered, the forks will move. But for small irregularities such as pavement joints, the forks are virtually rigid.

A t this time there is no simple or inexpensive cure for the problem. Switching to S&W 35/65 fork springs will improve the ride over some surfaces, but doesn’t deal with the problem directly.

Until a practical cure is available, you’ll have to either bear with it, or adapt a different set of forks to your bike.

HONDA IGNITION MODIFICATIONS

I have been unable to get any information on modifiying the electrics on my moderately warmed-over 1971 Honda SL175. Generally, I get about this far and whoever I’m talking to rolls his or her eyes and wonders why I don’t put down $1500 for a real dirt bike. I’ll spare you my arguments—suffice it to say I like my bike. I’ve had other equally unlikely bikes and generally found great advantages in upgrading ignition parts to automotive standards. But I’ve never done this to a Twin before.

How can I set up K-Mart coils to fire this beast? I think it’s 180 deg. opposed firing but I’m not sure. Could you give me a brief description of what components this will require and how I can set them up. I’m a reasonably proficient mechanic and need only basic instructions.

After accumulating a two-foot stack of newsstand publications, I’ve finally bought a subscription to your magazine. Not wishing to embarrass you with the usual palaver, I’ll just say many thanks for a good general overview of most aspects of motorcycling.

John Bloom Kure Beach, N.C.

There are two methods to hook up automotive coils to your Twin, one requiring the use of ballast resistors.

Using the resistor method, you will need a pair of 12-volt automotive ballast resistors, one for each coil.

One end of each ballast resistor should be connected to the ignition hot lead. Connect each of the free ballast resistors ends to the positive (+) side of a coil. Connect the negative (-) sides of the coils together, and to the wire leading from the ignition points.

Connecting the coils without using resistors is even more simple. Connect the ignition hot lead to the positive side of one coil. Connect the side of that coil to the positive side of the second coil. Connect the negative side of the second coil to the breaker point lead.

The series connection (no resistors) is probably the best way to go, as it draws less current than the other method. Its spark intensity might be slightly less, however, but still should be adequate.

BURNED UP

Last summer four friends and I each bought new 1974 Yamaha SC500s. We do a lot of trail riding and hillclimbing, and have been having a lot of trouble with the electronic ignitions. The pulser coils keep burning out. I have replaced four in mine and one other guy has replaced seven. The three remaining bikes have required one each. They don’t burn out as easily when we hillclimb, but when we go trail riding they start acting up in about an hour or so. The engines miss at low rpm, but if you run them at a high rpm they don’t act up as much. I took mine back to the dealer, but he couldn’t find anything wrong with it. I also asked another dealer about it, and he said that Yamaha made a stronger coil. I have since burned two of these up. One of the other guys has already used five of them.

I am wondering if anyone else is having the same problem. The coils cost $15 each and are hard to get because the dealers can’t keep them in stock. I would be grateful for any help you can offer.

Jimmy Backus Dixie, W. Va.

According to a technical representative at Yamaha International Corporation, a problem did indeed exist with certain SC400 electrics. A program had been instigated whereby an exchange of the defective components was often possible at dealer level. To be eligible, a bike’s serial number had to be present on an authorized list provided by Yamaha. We suggest you contact your dealer for more specific information.

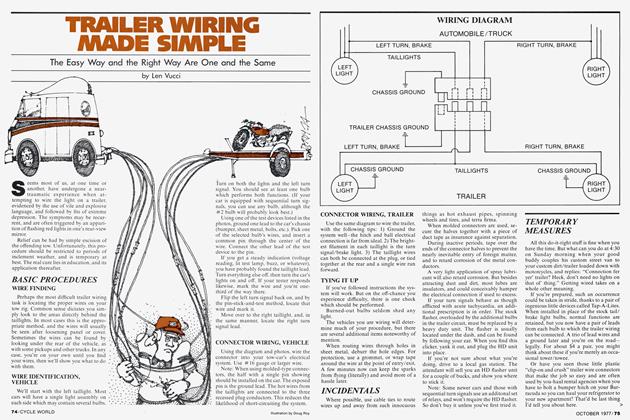

SHOCKING!

I just finished reading the test on shocks in your April issue. I know enough about Works Performance shocks that I can tell they are upside down. Will you please tell me if this is the position in which you tested them. If so, please tell me why. Please print this, my family thinks this is a joke!

John Closson Pacific Palisades, Calif.

The picture was flopped, and no, we did not test them that way. Some readers may have noticed the pictures of the Works Performance and S& W shocks were transposed in the May issue. Our apologies are offered for these obvious errors.

View Full Issue

View Full Issue