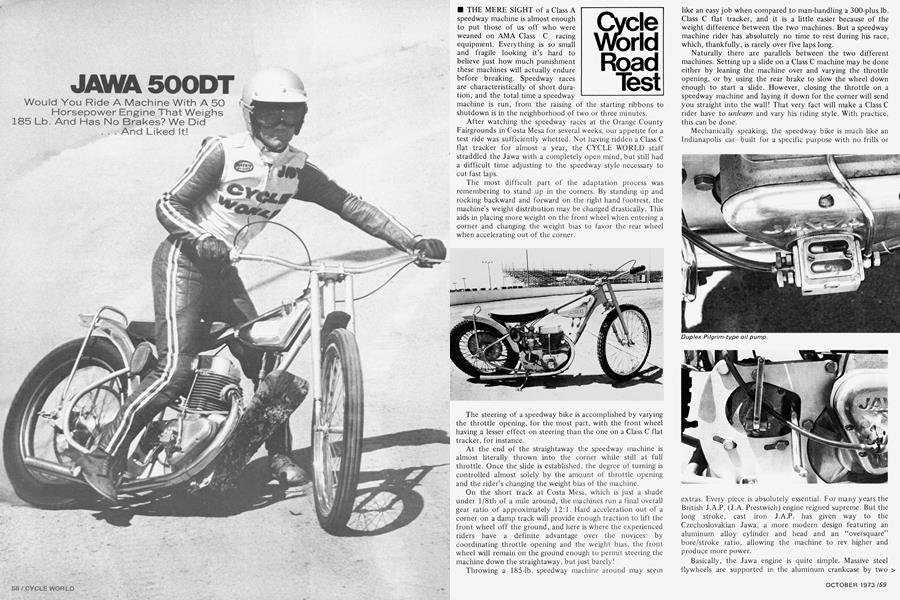

JAWA 500DT

Would You Ride A Machine With A 50 Horsepower Engine That Weighs 185 Lb. And Has No Brakes? We Did . . . And Liked It!

Cycle World Road Test

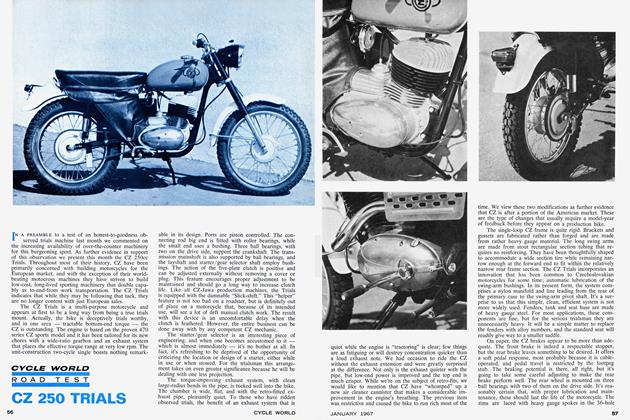

THE MERE SIGHT of a Class A speedway machine is almost enough to put those of us off who were weaned on AMA Class C racing equipment. Everything is so small and fragile looking it’s hard to believe just how much punishment these machines will actually endure before breaking. Speedway races are characteristically of short duration, and the total time a speedway

machine is run, from the raising of the starting ribbons to shutdown is in the neighborhood of two or three minutes. After watching the speedway races at the Orange County Fairgrounds in Costa Mesa for several weeks, our appetite for a test ride was sufficiently whetted. Not having ridden a Class C flat tracker for almost a year, the CYCLE WORLD staff straddled the Jawa with a completely open mind, but still had a difficult time adjusting to the speedway style necessary to cut fast laps. The most difficult part of the adaptation process was remembering to stand up in the corners. By standing up and rocking backward and forward on the right hand footrest, the machine’s weight distribution may be changed drastically. This aids in placing more weight on the front wheel when entering a corner and changing the weight bias to favor the rear wheel when accelerating out of the corner.

The steering of a speedway bike is accomplished by varying the throttle opening, for the most part, with the front wheel having a lesser effect on steering than the one on a Class C flat tracker, for instance.

At the end of the straightaway the speedway machine is almost literally thrown into the corner while still at full throttle. Once the slide is established, the degree of turning is controlled almost solely by the amount of throttle opening and the rider’s changing the weight bias of the machine.

On the short track at Costa Mesa, which is just a shade under 1 /8thof a mile around, the machines run a final overall gear ratio of approximately 12:1. Hard acceleration out of a corner on a damp track will provide enough traction to lift the front wheel off the ground, and here is where the experienced riders have a definite advantage over the novices: by coordinating throttle opening and the weight bias, the front wheel will remain on the ground enough to permit steering the machine down the straightaway, but just barely!

Throwing a 185-lb. speedway machine around may seem

like an easy job when compared to man-handling a 300-plus lb. Class C flat tracker, and it is a little easier because of the weight difference between the two machines. But a speedway machine rider has absolutely no time to rest during his race, which, thankfully, is rarely over five laps long.

Naturally there are parallels between the two different machines. Setting up a slide on a Class C machine may be done either by leaning the machine over and varying the throttle opening, or by using the rear brake to slow the wheel down enough to start a slide. However, closing the throttle on a speedway machine and laying it down for the corner will send you straight into the wall! That very fact will make a Class C rider have to unlearn and vary his riding style. With practice, this can be done.

Mechanically speaking, the speedway bike is much like an Indianapolis car—built for a specific purpose with no frills or

extras. Every piece is absolutely essential. For many years the British J.A.P. (J.A. Prestwich) engine reigned supreme. But the long stroke, cast iron J.A.P. has given way to the Czechoslovakian Jawa, a more modern design featuring an aluminum alloy cylinder and head and an “oversquare” bore/stroke ratio, allowing the machine to rev higher and produce more power.

Basically, the Jawa engine is quite simple. Massive steel flywheels are supported in the aluminum crankcase by two large roller bearings with 20 rollers on each side, placed in a staggered fashion in an aluminum alloy cage. The total width of the bearing cage is 34mm, offering plenty of support for the heavy flywheels, connecting rod and piston. The connecting rod rides on double-row roller bearings at the big end and the piston is supported by a bushing.

A gear on the right hand end of the crankshaft drives an idler gear, which in turn spins the two cams, one for each valve. This high placement of the cams allows shorter, and therefore lighter, pushrods to be used, decreasing the weight of the valve train and allowing high rpm operation. The exhaust cam gear is used to drive the magneto.

Flat tappets are used to transmit the motion of the cams to the pushrods, and the cams themselves are ground so that they provide a “textbook” operating sequence: the initial lift is very gradual, speeding up near maximum opening, and then slowing back down as the cam’s ramp nears its end. This, in part, is responsible for the long life of the Jawa’s valve actuating mechanism.

Designed for using methyl alcohol for fuel, the valve timing limits are: intake valve opens 57 to 61-deg. btdc and closes 80 to 88-deg. abdc; the exhaust valve opens 94 to 100-deg. bbdc and closes 42 to 47-deg. atdc, with a total duration of 340 deg. Total lift, measured at the valve, is 0.360 in.

A 35mm carburetor supplies the engine with fuel and moderately large valves (47mm intake, 42mm exhaust) fill and empty the hemispherical combustion chamber. A straightthrough exhaust pipe is used and has slots cut into the inside rear portion of the tailpipe to reduce noise, a rule which was put into effect at the request of the British.

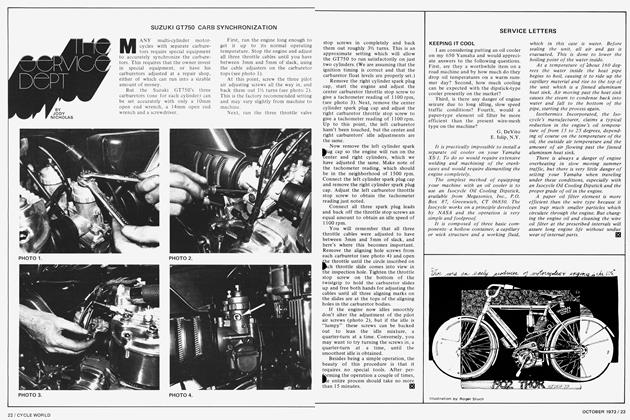

Because speedway races are short, a small, rubber mounted fuel tank which holds a little over two quarts is fitted and the lubricating oil supply, which is approximately one-half quart, is carried in the frame. A total loss lubrication system is employed and a duplex Pilgrim-type oil pump is used. The outer portion of this pump supplies oil to the crankshaft and connecting rod bearings, and the inner one feeds oil up an outside line to the rocker arms and valve mechanism. This drains back down to the bottom of the crankcase, lubricating the timing gears and cams before being expelled from the engine onto the track.

We went to visit Ed Schafer at Speedway Research & Specialties in Santa Ana, Calif., and learned a great deal about the preparation and maintenance of a successful speedway machine. Ed builds and tunes the Jawa that U.S. Champion Rick Woods rides, and is responsible for the preparation and repair of many speedway machines in the Southern California area.

Although a Jawa 500DT is ready to run as delivered, there are many things which can be done to make them perform even better. “It’s best to strip a new machine down for inspection even before it is raced. For example, I’ve found cam gear ends blued from heat from the machines being run at the factory,” Ed stated “And it’s also a good idea to check the cam timing and ignition timing, and then run the engine at low rpm to fully seat the moving parts before the bike is raced.”

We had heard that some of the competitors in this area were using nitromethane in their fuel, and Ed verified it by saying that it provides a substantial boost in power with no alterations to the engine other than properly jetting the carburetor. Fuel mixtures containing 10 to 30 percent nitro are used by most of the top speedway stars in California.

Ed has run into some problems with the standard Jawa pistons which are a full skirt design with three rings: two compression and one oil control ring. The standard piston gives an actual compression ratio of 13.85:1, which is perfect for the straight methanol used in Europe and works well enough. However, the pistons aren’t cam-ground (they are perfectly round) and provide excess drag inside the engine.

Working with Forgedtrue, Ed came up with a slipper-skirt piston with only two rings, a Dykes-type upper ring and a three-piece oil control ring, with a medium cam grind which lowers piston drag against the cylinder wall. The new pistons provide a compression ratio of 13.65:1 which helps keep the engine heat down when running a nitro mix.

The Jawa unit is extremely reliable. Riders in the Southern California area who race four nights a week find it necessary to rebuild the top ends of the engines every two or three weeks while the lower ends may be run a full season without attention.

A dry clutch with four friction and four steel plates transmits the power from the crankshaft to the two-speed transmission. Althouth the Jawa is available with a single-speed in/out transmission, most are ordered with the two-speed unit which is necessary for the longer tracks found in Europe.

Compared with an AMA Class C flat track machine, the speedway rigs are quite a bit different. A very steep steering head angle of 19 deg. and an even steeper fork angle of 18 deg., coupled with a steering trail measurement of 0.75 in. make the Jawas steer quickly and effortlessly. This steering geometry, coupled with a short 52-in. wheelbase aids turning the machines on the short tracks on which they compete.

A new Jawa 500DT has a claimed brake horsepower rating of 50 bhp at an unspecified rpm, but Ed has run brand new machines on his dynamometer and usually finds a power

output of about 41 bhp at the rear wheel. The highest power output he has recorded for one of his special engines running on a nitro mix is 63 bhp at 7800 rpm. This gives a power/weight ratio of 3 lb./bhp! Aside from the special pistons he uses, the remainder of the engine components are standard except the S&W valve springs.

A new Jawa 500DT comes with a 3.50-19-in. rear tire which is good for beginners to start on, but the really fast competitors here in California use a special 2.75-22-in. rear tire. This narrow section tire gives better traction and being taller, it also reduces the fork angle and trail slightly. These tires are used extensively in Europe, but the British League specifies a 3.50-19-in. rear tire.

Looking more like a bicycle frame than one used to hold 185 lb. of motorcycle together and support the weight of a rider under often strenuous conditions, the frame’s toptube and single downtube are a mere 1.18-in. in diameter. The entire rear section, which is attached to the main frame by four bolts, is made of smaller 0.87-in. diameter tubing. Front fork stanchions are the same size and the forks provide just under two inches of travel while the rear section is unsprung. Most speedway tracks are fairly smooth, however, and there is no need for more suspension travel.

An additional support is in the form of a tube, bolted at one end beneath the left hand side of the seat and at the other end to the top rear engine mounting bolt. The engine and transmission are supported in the frame by aluminum alloy mounting plates and since there is no bottom frame tube, the engine and gearbox literally “hang in there!”

Aside from the rather high cost of fuel and the expensive rear tires, speedway racing is relatively inexpensive compared to AMA Class C flat track racing. And, with four races a week in the Southern California area, some riders earn as much as $25,000 a year by racing speedway!

JAWA

500DT

$1550

View Full Issue

View Full Issue