Reed Valve Induction For The 250 Bultaco

DALE HERBRANDSON

IN THE MAY ’72 issue we looked at Yamaha's experience in converting its piston-timed-intake engines to reed induction. Its results showed improved engine performance at all values of engine rpm for both the Enduro and MX engines. This success makes one wonder if this type of performance can be attained using a bolt-on reed kit on some other motorcycle. We decided to find out. Both a dynamometer evaluation and a road test were to be performed.

A 250 Bultaco Mark IV Matador Six Day Trials replica was chosen as a test machine because of its excellent tractability in the engine department. This engine, with its piston-timed inlet, will pull well from 3000 rpm without complaining and yet buzz to 8000 rpm when the need arises. The port timing which we measured on this engine has the exhaust opening 95 degrees after tdc, with the transfer ports opening 22 degrees later. The total duration of the piston-timed inlet is 150 degrees.

The plan for the dynamometer sequence was to test a carefully prepared stock engine as a base line. The. engine would then be converted to reed induction without altering the port timing, exhaust system, carburetor size, air cleaner, etc.

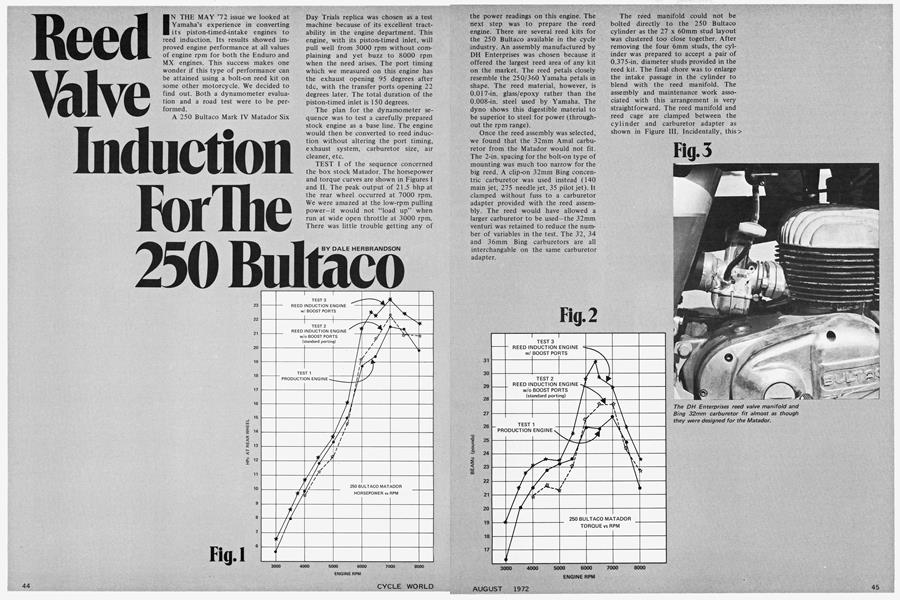

TEST I of the sequence concerned the box stock Matador. The horsepower and torque curves are shown in Figures I and II. The peak output of 21.5 bhp at the rear wheel occurred at 7000 rpm. We were amazed at the low-rpm pulling power—it would not “load up” when run at wide open throttle at 3000 rpm. There was little trouble getting any of the power readings on this engine. The next step was to prepare the reed engine. There are several reed kits for the 250 Bultaco available in the cycle industry. An assembly manufactured by DH Enterprises was chosen because it offered the largest reed area of any kit on the market. The reed petals closely resemble the 250/360 Yamaha petals in shape. The reed material, however, is 0.017-in. glass/epoxy rather than the 0.008-in. steel used by Yamaha. The dyno shows this digestible material to be superior to steel for power (throughout the rpm range).

Once the reed assembly was selected, we found that the 32mm Amal carburetor from the Matador would not fit. The 2-in. spacing for the bolt-on type of mounting was much too narrow for the big reed. A clip-on 32mm Bing concentric carburetor was used instead (140 main jet, 275 needle jet, 35 pilot jet). It clamped without fuss to a carburetor adapter provided with the reed assembly. The reed would have allowed a larger carburetor to be used-the 32mm venturi was retained to reduce the number of variables in the test. The 32, 34 and 36mm Bing carburetors are all interchangable on the same carburetor adapter.

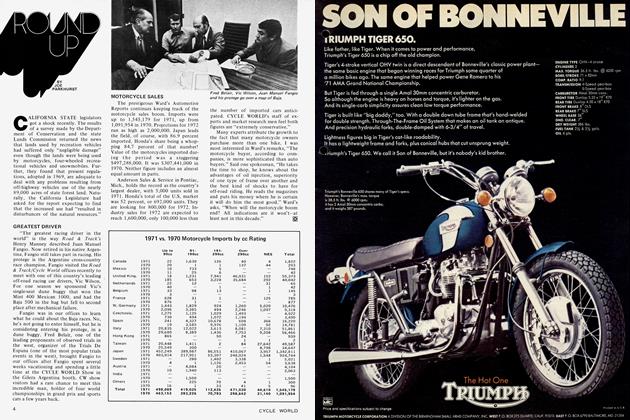

The reed manifold could not be bolted directly to the 250 Bultaco cylinder as the 27 x 60mm stud layout was clustered too close together. After removing the four 6mm studs, the cylinder was prepared to accept a pair of 0.375-in. diameter studs provided in the reed kit. The final chore was to enlarge the intake passage in the cylinder to blend with the reed manifold. The assembly and maintenance work associated with this arrangement is very straightforward. The reed manifold and reed cage are clamped between the cylinder and carburetor adapter as shown in Figure III. Incidentally, this> manifold bolts directly to the 360 Bultaco, as the 36 x 70mm stud layout is more generous than that of the 250.

The reed engine prepared for TEST 2 was to have only the intake passage and piston modified to allow the reed to breathe properly. The holes cut into the piston, shown in Figure IV, resulted in a total inlet duration at the piston of 260 degrees for the reed engine. This duration could have been increased to 360 degrees for TEST 2, for it is the reed and not the piston which now controls the inlet air flow. These large holes would have made the piston unfit for TEST 3 as the boost port engine must use the piston to isolate the boost ports from the crankcase. The “boost porting” made possible with the reed was not to be incorporated until TEST 3.

TEST 2 in Figure I shows the result of converting from the stock pistontimed inlet to the reed induction. No other engine modifications were made. Below 5600 rpm, the stock engine had better power than the reed engine. This happens very frequently when the piston-timed inlet engines are tuned for good low-end power. The torque shown in Figure II and the peak power in Figure I was better, however, with the reed engine. If the 150 degree inlet duration of the stock engine had been increased to around 170 degrees, we would have found an output closely resembling that of the TEST 2 reed engine. The reed itself is not responsible for the big gains in power seen on many machines. The “boost porting” that is made possible with the reed gives the big performance gain.

TEST 2 was strictly a dyno run to allow one to appreciate the value of the porting performed for TEST 3. The bike was not road tested in the TEST 2 state of tune.

The big advantage with reed induction accrues from the fact that the rear of the cylinder no longer has to control the inlet air. This large area on the cylinder bore can be used for additional transfer porting. These auxiliary transfer passages function as boost ports as they do not breathe from the crankcase. The photographs in Figure V show a before and after view of the cylinder. The ports in the modified cylinder were formed using a milling machine with a 0.50-in. diameter cutter tilted at 25 degrees from the cylinder axis. The finished shape of these ports is conservative as they have a round contour at the top (instead of square). The ports on the test engine opened with the main transfer passages. Testing after the 250 Bultaco sequence was completed indicates that these boost ports should be around 1mm higher than the main transfer passages for best power.

(Continued on page 120)

Continued from page 46

TEST 3 outperformed the previous two runs by a comfortable margin. The addition of the pair of boost ports, as conservative as they were, transformed the reed engine. At 3000 rpm, for example, the beam reading on the dyno was raised from 16.3 lb. in TEST 1 to 19.0 lb. This amounts to a torque increase of over 16 percent. The peak beam reading was raised from 26.7 lb. at 7000 rpm for the piston-ported engine to 30.8 lb. for the reed engine with boost ports. This improvement is just under 16 percent. Also note that the spread between the peak torque and peak power is 650 rpm for the reed engine. The stock engine has the torque peak and power peak at the same rpm. The greater these peaks are spread, the easier the machine is to ride. A graphic summary of the dyno testing is shown in Figures I and II. The reed engine has a comfortable performance margin over the stock engine. We couldn’t wait to ride it.... m