ALL ABOUT PISTON RINGS

WILLIAM HAMPTON

ALTHOUGH IT'S NOT too impressive looking, a piston ring must perform vital functions under severe stress and thermal loadings. This is particularly true of today's engines that often operate at piston speeds of 4000 ft./min. So that you may better understand this component, this article makes an in-depth analysis of it.

To begin with, you might say that the piston ring, as it slides up and down the cylinder wall, is functioning like a bearing. It also has the added task of sealing off the combustion chamber to keep the gases from escaping past the piston into the crankcase.

In the case of a four-stroke engine, the lowermost oilscraper ring must meter and distribute the exact amount of oil to keep the cylinder wall properly lubricated. Usually, four-stroke engines will have two compression rings and one oil-scraper ring. Some high-performance engines, though, may have just one compression ring and an oil-scraper ring. Two-stroke engines usually have one or two compression rings, depending on the performance characteristics of the engine.

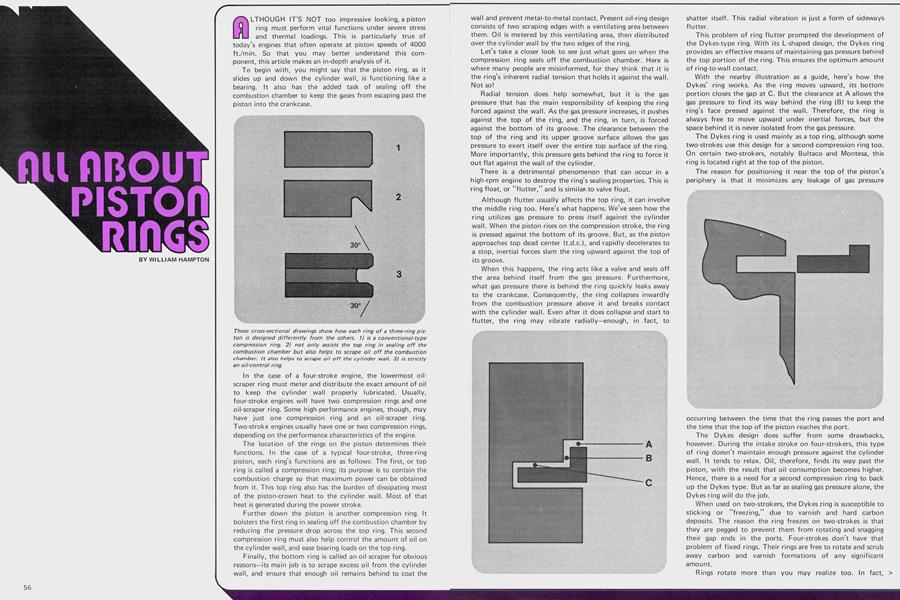

The location of the rings on the piston determines their functions. In the case of a typical four-stroke, three-ring piston, each ring's functions are as follows: The first, or top ring is called a compression ring; its purpose is to contain the combustion charge so that maximum power can be obtained from it. This top ring also has the burden of dissipating most of the piston-crown heat to the cylinder wall. Most of that heat is generated during the power stroke.

Further down the piston is another compression ring. It bolsters the first ring in sealing off the combustion chamber by reducing the pressure drop across the top ring. This second compression ring must also help control the amount of oil on the cylinder wall, and ease bearing loads on the top ring.

Finally, the bottom ring is called an oil scraper for obvious reasons—its main job is to scrape excess oil from the cylinder wall, and ensure that enough oil remains behind to coat the wall and prevent metal-to-metal contact. Present oil-ring design consists of two scraping edges with a ventilating area between them. Oil is metered by this ventilating area, then distributed over the cylinder wall by the two edges of the ring.

Let's take a closer look to see just what goes on when the compression ring seals off the combustion chamber. Here is where many people are misinformed, for they think that it is the ring's inherent radial tension that holds it against the wall. Not so!

Radial tension does help somewhat, but it is the gas pressure that has the main responsibility of keeping the ring forced against the wall. As the gas pressure increases, it pushes against the top of the ring, and the ring, in turn, is forced against the bottom of its groove. The clearance between the top of the ring and its upper groove surface allows the gas pressure to exert itself over the entire top surface of the ring. More importantly, this pressure gets behind the ring to force it out flat against the wall of the cylinder.

There is a detrimental phenomenon that can occur in a high-rpm engine to destroy the ring's sealing properties. This is ring float, or "flutter," and is similar.to valve float.

Although flutter usually affects the top ring, it can involve the middle ring too. Here's what happens. We've seen how the ring utilizes gas pressure to press itself against the cylinder wall. When the piston rises on the compression stroke, the ring is pressed against the bottom of its groove. But, as the piston approaches top dead center (t.d.c.), and rapidly decelerates to a stop, inertial forces slam the ring upward against the top of its groove.

When this happens, the ring acts like a valve and seals off the area behind itself from the gas pressure. Furthermore, what gas pressure there is behind the ring quickly leaks away to the crankcase. Consequently, the ring collapses inwardly from the combustion pressure above it and breaks contact with the cylinder wall. Even after it does collapse and start to flutter, the ring may vibrate radially—enough, in fact, to shatter itself. This radial vibration is just a form of sideways flutter.

This problem of ring flutter prompted the development of the Dykes-type ring. With its L-shaped design, the Dykes ring provides an effective means of maintaining gas pressure behind the top portion of the ring. This ensures the optimum amount of ring-to-wall contact.

With the nearby illustration as a guide, here's how the Dykes' ring works. As the ring moves upward, its bottom portion closes the gap at C. But the clearance at A allows the gas pressure to find its way behind the ring (B) to keep the ring's face pressed against the wall. Therefore, the ring is always free to move upward under inertial forces, but the space behind it is never isolated from the gas pressure.

The Dykes ring is used mainly as a top ring, although some two-strokes use this design for a second compression ring too. On certain two-strokers, notably Bultaco and Montesa, this ring is located right at the top of the piston.

The reason for positioning it near the top of the piston's periphery is that it minimizes any leakage of gas pressure occurring between the time that the ring passes the port and the time that the top of the piston reaches the port.

The Dykes design does suffer from some drawbacks, however. During the intake stroke on four-strokers, this type of ring doesn't maintain enough pressure against the cylinder wall. It tends to relax. Oil, therefore, finds its way past the piston, with the result that oil consumption becomes higher. Hence, there is a need for a second compression ring to back up the Dykes type. But as far as sealing gas pressure alone, the Dykes ring will do the job.

When used on two-strokers, the Dykes ring is susceptible to sticking or "freezing," due to varnish and hard carbon deposits. The reason the ring freezes on two-strokes is that they are pegged to prevent them from rotating and snagging their gap ends in the ports. Four-strokes don't have that problem of fixed rings. Their rings are free to rotate and scrub away carbon and varnish formations of any significant amount.

Rings rotate more than you may realize too. In fact, > extensive tests have proven that the ratio of ring rotation to crankshaft rotation is about 1:1000. In other words, for every 1000 rpm of the crank, a ring will rotate around its piston once. In an engine turning 8000 rpm, the rings are circling the piston about eight times per minute.

Most of the ring rotation is due to the slight offset of the crankshaft axis relative to the crankpin axis. Although this offset is only a fraction of a degree, it's enough to impart a swashing motion to the piston as it travels up and down in the bore. This swashing motion forces the ring to jam itself against its groove at some points, while at other points the ring will virtually float. It is this combination of loading/unloading the ring's periphery that imparts enough inertia to the ring to make it rotate in its groove.

This ring-rotation factor poses a pertinent question: Does it do any good to stagger the ring gaps during ring replacement? Not really! In those first few moments of engine operation, the gap settings are going to change. But contrary to what some may think, having the rings' gaps close to each other, or even in line with each other, isn't going to allow significant blow-by to occur. Even at a conservative 4000 rpm, the combustion gases have only seven-thousandths of a second to influence the piston. Incidentally, most blow-by occurs during the last phase of the compression stroke and the first phase of the power stroke.

Blow-by is more of a problem in an engine operating at low rpm, simply because there is more time for the gases to find their way past the piston or through the ring gaps. This problem of excessive blow-by is one reason why sloweroperating engines have two or three rings instead of just one.

As mentioned earlier in the section on ring flutter, after the piston comes to an abrupt stop at either the top or bottom of its stroke, the ring's inertial forces cause it to keep moving. Consequently, at t.d.c. the ring pounds the top of its groove, and at b.d.c., the ring's momentum slams it into the bottom of its groove. When the top and bottom of a groove become badly worn, gas pressure escapes. In severe cases where there is a lot of wear, the ring can flop around and break.

Furthermore, the upper surface of the top compression ring's groove wears more rapidly than any of the other grooves because it's exposed to maximum combustion temperatures and pressures and to the dirt that enters with the intake charge. In certain instances when a high-rpm engine is overworked, the top ring will flutter violently until the ring land gives way and a ring breaks. It's not unusual to have the damage spread and cause complete engine failure. A badly battered ring groove may also allow the ring to twist somewhat and lose contact with the cylinder wall. The ring edges then become rounded and lose much of their sealing effectiveness.

To minimize the effects of the battering that rings can inflict on their grooves, high-rpm engines use narrow (and lighter) rings to reduce inertial forces. Narrow-width rings also don't have as much contact area with the cylinder wall, lowering drag or friction. But this advantage of lowering drag does put higher loadings on the rings' faces. Consequently, they'll wear faster than wider rings.

The rate of ring and groove wear is further affected by the air filtration system. If no air cleaner is fitted, the life of the rings, piston and cylinder wall is shortened considerably by the dirt that enters with the intake charge. Even air leaks around the intake manifold or a porous air cleaner can allow enough dirt to enter the cylinder and cause damage.

Regardless of whether they wear from hard use or from something else, the rings must be replaced at some period in the life of an engine. This need for replacement will manifest itself by a falling off in performance caused by a loss of compression. Another indication of worn rings is excessive oil consumption. There are no predetermined mileages for replacing rings either. One engine might need them replaced at 2000 miles; another may go 20,000 miles before it needs new rings.

Ring life depends on how the engine is broken in and operated thereafter. For now, however, let's assume that your engine's performance indicates ring replacement is necessary. If you're doing your own work, closely examine the face of the ring to be replaced. Any discoloration means that it has not been contacting the cylinder wall. The ring face should have a shiny appearance.

Next check for bore wear. If the cylinder doesn't need to be ''rebored,'' at least have it lightly honed out or de-glazed. This will remove score marks, glazing, or varnish deposits from the wall so that it can better seat the rings' faces. In fact, the best finish is a cross-hatch design, which has been found to seat rings faster than that method where the bore is honed with spiral grooves rotating in one direction only.

Also, engineers have found that having a bore in one direction only causes the rings to rotate more. Furthermore, honing in just one direction produces a helix-shaped bore, instead of the cylindrically formed bore that results from honing in both directions.

When checking a new ring for proper fit, its end gap must be measured to conform to the manufacturer's specs. This measurement is made both at the lowermost, unworn portion of the bore, and at the point of maximum wear. The point of maximum bore wear will be át the top of the stroke where temperatures are highest and lubrication least. And when measuring the gap, make sure that the ring sits in the bore squarely. Otherwise, inaccurate readings will result. The easy way to position the ring is to use the piston as a guide; insert the ring into the bore, followed by the piston, upside down.

When replacing rings other than the Dykes type on the piston, be careful not to mount them upside down. Some rings are beveled on the inside, and, if installed upside down, excessive blow-by and consequent loss of power will result.

Although most rings are of cast-iron construction, the use of chrome-plated rings can extend the intervals between ring replacement considerably. But under no circumstances should chromed rings be used with a chromed bore because sooner or later, the chrome plating will peel off either the ring or the cylinder wall. If that happens, you can write off the piston and possibly the cylinder.

Chrome-steel rings last longer, but they require a longer break-in period. Actually, nodular cast iron is the best material for rings, as its ductility and long-wearing properties make it a practical choice for reasons of easier break-in and economical replacement.

There are more advantages of cast iron over other metals. For example, it is not only an excellent bearing material, but it can be machined to a tolerance of 0.0001 of an inch. That's equivalent to about one-thirtieth the thickness of a human hair.

Regardless of how it's designed or constructed, any new piston ring requires a certain amount of break-in if it's to seat properly against the cylinder wall. A new ring can be said to be broken in when it stabilizes oil consumption and prevents excessive blow-by.

Actually, if the right technique is used, new rings can be seated during the first 50 miles or so. The technique actually consists of two phases:

(1) Every so often give the engine a full-throttle burst for a few seconds; (2) then snap the throttle shut and coast for a few more seconds. By giving the engine full power, gas pressure forces the rings out against the cylinder wall, thereby allowing them to make full contact. Snapping the throttle shut causes a vacuum in the cylinder that draws extra oil up the cylinder wall. This action minimizes the risk of metal-to-metal contact and gives the engine a brief, but important, breathing spell that helps prevent overheating and a possible piston seizure.

This throttle-on/throttle-off technique ensures that the rings seat under realistic operating conditions. If the rings don't seat during the early stages, chances are they won't seat until 2000 miles or more have passed.

In summation, breaking in new ring£ isn't all that complicated. But the manner in which you do it will have an important effect on your bike's performance. After the rings are broken in, you can extend their life considerably by keeping the oil supply fresh and full and by using a good air cleaner. That's not demanding too much, considering what you'll gain in better performance and longer engine life. ®

View Full Issue

View Full Issue