HAGGLUND XM72 PROTOTYPE

One Futuristic Design That Stretches The Imagination

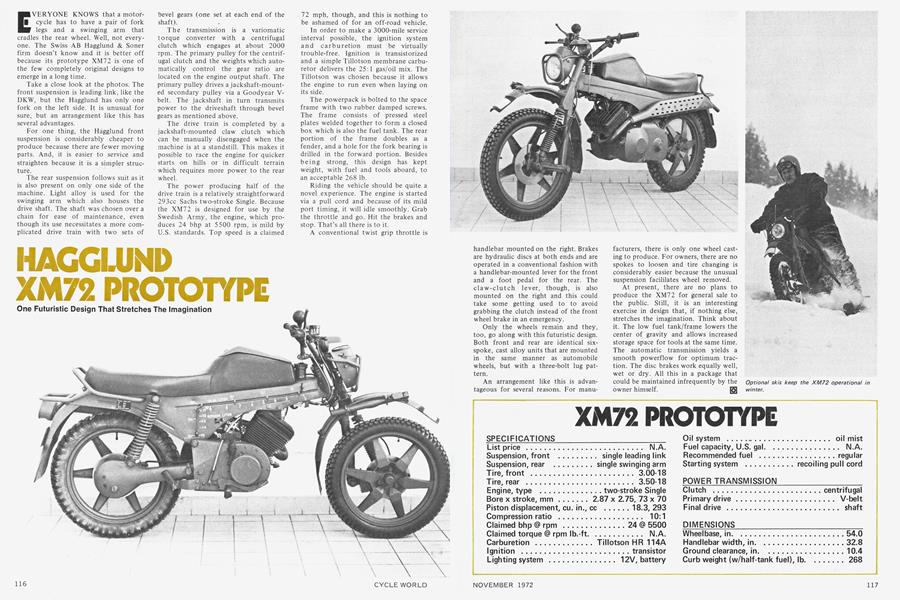

EVERYONE KNOWS that a motorcycle has to have a pair of fork legs and a swinging arm that cradles the rear wheel. Well, not everyone. The Swiss AB Hagglund & Soner firm doesn’t know and it is better off because its prototype XM72 is one of the few completely original designs to emerge in a long time.

Take a close look at the photos. The front suspension is leading link, like the DKW, but the Hagglund has only one fork on the left side. It is unusual for sure, but an arrangement like this has several advantages.

For one thing, the Hagglund front suspension is considerably cheaper to produce because there are fewer moving parts. And, it is easier to service and straighten because it is a simpler structure.

The rear suspension follows suit as it is also present on only one side of the machine. Light alloy is used for the swinging arm which also houses the drive shaft. The shaft was chosen over a chain for ease of maintenance, even though its use necessitates a more complicated drive train with two sets of bevel gears (one set at each end of the shaft).

The transmission is a variomatic torque converter with a centrifugal clutch which engages at about 2000 rpm. The primary pulley for the centrifugal clutch and the weights which automatically control the gear ratio are located on the engine output shaft. The primary pulley drives a jackshaft-mounted secondary pulley via a Goodyear Vbelt. The jackshaft in turn transmits power to the driveshaft through bevel gears as mentioned above.

The drive train is completed by a jackshaft-mounted claw clutch which can be manually disengaged when the machine is at a standstill. This makes it possible to race the engine for quicker starts on hills or in difficult terrain which requires more power to the rear wheel.

The power producing half of the drive train is a relatively straightforward 293cc Sachs two-stroke Single. Because the XM72 is designed for use by the Swedish Army, the engine, which produces 24 bhp at 5500 rpm, is mild by U.S. standards. Top speed is a claimed 72 mph, though, and this is nothing to be ashamed of for an off-road vehicle.

In order to make a 3000-mile service interval possible, the ignition system and carburetion must be virtually trouble-free. Ignition is transistorized and a simple Tillotson membrane carburetor delivers the 25:1 gas/oil mix. The Tillotson was chosen because it allows the engine to run even when laying on its side.

The powerpack is bolted to the space frame with two rubber damped screws. The frame consists of pressed steel plates welded together to form a closed box which is also the fuel tank. The rear portion of the frame doubles as a fender, and a hole for the fork bearing is drilled in the forward portion. Besides being strong, this design has kept weight, with fuel and tools aboard, to an acceptable 268 lb.

Riding the vehicle should be quite a novel experience. The engine is started via a pull cord and because of its mild port timing, it will idle smoothly. Grab the throttle and go. Hit the brakes and stop. That’s all there is to it.

A conventional twist grip throttle is handlebar mounted on the right. Brakes are hydraulic discs at both ends and are operated in a conventional fashion with a handlebar-mounted lever for the front and a foot pedal for the rear. The claw-clutch lever, though, is also mounted on the right and this could take some getting used to to avoid grabbing the clutch instead of the front wheel brake in an emergency.

Only the wheels remain and they, too, go along with this futuristic design. Both front and rear are identical sixspoke, cast alloy units that are mounted in the same manner as automobile wheels, but with a three-bolt lug pattern.

An arrangement like this is advantageous for several reasons. For manufacturers, there is only one wheel casting to produce. For owners, there are no spokes to loosen and tire changing is considerably easier because the unusual suspension facililates wheel removed.

At present, there are no plans to produce the XM72 for general sale to the public. Still, it is an interesting exercise in design that, if nothing else, stretches the imagination. Think about it. The low fuel tank/frame lowers the center of gravity and allows increased storage space for tools at the same time. The automatic transmission yields a smooth powerflow for optimum traction. The disc brakes work equally well, wet or dry. All this in a package that could be maintained infrequently by the owner himself. 151

XM72 PROTOTYPE

View Full Issue

View Full Issue