THE SERVICE DEPARTMENT

JOHN DUNN

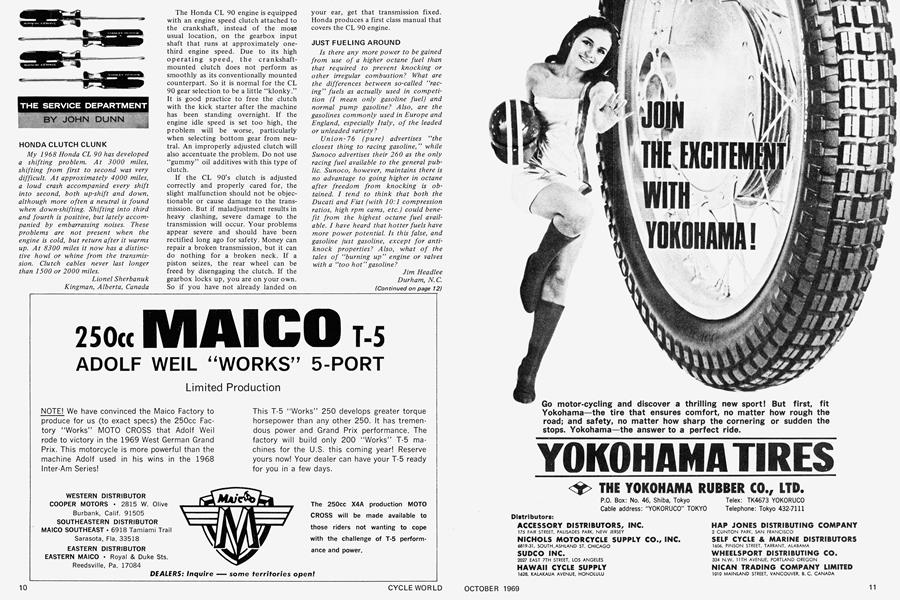

HONDA CLUTCH CLUNK

My 1968 Honda CL 90 has developed a shifting problem. At 3000 miles, shifting from first to second was very difficult. At approximately 4000 miles, a loud crash accompanied every shift into second, both up-shift and down, although more often a neutral is found when down-shifting. Shifting into third and fourth is positive, but lately accompanied by embarrassing noises. These problems are not present when the engine is cold, but return after it warms up. At 8300 miles it now has a distinctive howl or whine from the transmission. Clutch cables never last longer than 1500 or 2000 miles. Lionel Sherbanuk Kingman, Alberta, Canada

The Honda CL 90 engine is equipped with an engine speed clutch attached to the crankshaft, instead of the more usual location, on the gearbox input shaft that runs at approximately onethird engine speed. Due to its high operating speed, the crankshaftmounted clutch does not perform as smoothly as its conventionally mounted counterpart. So it is normal for the CL 90 gear selection to be a little “klonky.” It is good practice to free the clutch with the kick starter after the machine has been standing overnight. If the engine idle speed is set too high, the problem will be worse, particularly when selecting bottom gear from neutral. An improperly adjusted clutch will also accentuate the problem. Do not use “gummy” oil additives with this type of clutch.

If the CL 90’s clutch is adjusted correctly and properly cared for, the slight malfunction should not be objectionable or cause damage to the transmission. But if maladjustment results in heavy clashing, severe damage to the transmission will occur. Your problems appear severe and should have been rectified long ago for safety. Money can repair a broken transmission, but it can do nothing for a broken neck. If a piston seizes, the rear wheel can be freed by disengaging the clutch. If the gearbox locks up, you are on your own. So if you have not already landed on your ear, get that transmission fixed. Honda produces a first class manual that covers the CL 90 engine.

JUST FUELING AROUND

Is there any more power to be gained from use of a higher octane fuel than that required to prevent knocking or other irregular combustion? What are the differences between so-called “racing” fuels as actually used in competition (I mean only gasoline fuel) and normal pump gasoline? Also, are the gasolines commonly used in Europe and England, especially Italy, of the leaded or unleaded variety?

Union-76 (pure) advertises “the closest thing to racing gasoline,” while Sunoco advertises their 260 as the only racing fuel available to the general public. Sunoco, however, maintains there is no advantage to going higher in octane after freedom from knocking is obtained. I tend to think that both the Ducati and Fiat (with 10:1 compression ratios, high rpm cams, etc.) could benefit from the highest octane fuel available. I have heard that hotter fuels have more power potential. Is this false, and gasoline just gasoline, except for antiknock properties? Also, what of the tales of “burning up” engine or valves with a “too hot”gasoline? Jim Headlee Durham, N.C.

(Continued on page 12)

Continued from page 10

This is a complex subject on which I can only generalize. Every engine design differs, particularly with respect to fuel octane requirements. Where one design with a given compression ratio will function efficiently on a given octane rating, another design with the same compression ratio may require either a higher or a lower octane rating to do its thing.

There is no advantage in having a higher anti-knock value in a fuel beyond what the engine needs. It must be pointed out, however, that an unneces sarily high anti-knock value is only undesirable economically rather than technically. The rate of propagation of the spark ignited flame does not depend on the anti-knock value (octane rating) of the fuel. It is mainly influenced by the air/fuel ratio, temperature, pressure, and heat loss to the cylinder wall.

No matter what the octane rating of the fuel, all gasolines have the same or nearly the same calorific value. Calorific value is the amount of heat a given quantity of fuel will release when burnt. The amount is given in Btu per lb. or Btu per gallon. A Btu is a unit of heat called a British thermal unit.

There is little choice among premium grade gasolines (rated between 100 and 105 octane) and racing gasolines of similar octane ratings. Premium grade gasoline, even of the same brand, varies depending on the local climatic condi tions. A fuel suitable in a warm climate might be unsuitable in a cold climate due to the differences of the ability of the fuel to vaporize. A fuel suitable for a warm climate would be difficult to start in a cold climate. Racing gasolines differ from the premium gasolines only in this and other minor respect~

It has been my experience that pre mium gasolines are comparable with the racing gasolines and other special racing gasolines that have a very high octane rating. Premium grade gasolines that are available today will not cause the "burn ing up" problems that you refer to. However, gasolines containing large quantities of lead can result in the rapid deterioration of valves and piston crowns.

BSA DILEMMA

I recently bought a used 1967 BSA 650-cc Mk III. I have had the engine tuned, and had new clutch plates and springs installed. The machine runs well, but the clutch slips in third gear. The dealer who worked on it has checked it out, and is puzzled. The slipping occurs in third gear when the engine is hot and revved over 3000 rpm. Ken Hamilton Hartford, Conn.

(Continued on page 14)

Continued from page 12

From the contents of your letter, it appears that the clutch slippage problem is being caused by an internal gearbox malfunction. It will therefore be necessary to remove the complete gear cluster for inspection.

The sliding pinion that engages both third and fourth gears is situated on the gearbox mainshaft. The mainshaft sliding pinion is equipped with engaging dogs at both ends. When the pinion is moved (by the selector fork) one way, it engages with similar dogs on a fixed pinion, thereby obtaining third gear. If the sliding pinion is moved in the opposite direction, the dogs on its other side engage with dogs on the main output gear, thereby obtaining fourth gear. If these dogs are badly or even partially worn, a great deal of side thrust is created (the dogs of each gear tend to force themselves apart). This puts considerable end load on the gearbox bearings and selector fork.

Because the clutch slip occurs only in third gear, this indicates that the dogs on the mainshaft fixed pinion and those on the sliding pinion are worn. This would exert considerable end pressure on the mainshaft, causing it to press heavily against the end cover bearing. If this bearing is worn or loose in its housing, the end pressure will move it out of its correct location. If this movement is excessive, the clutch actuating lever will come into contact with its operating fulcrum, which naturally will cause the clutch to partially disengage. If this is the cause of the problem, it is likely that when the clutch slips, tension can be felt at the clutch lever.

If this trouble is allowed to persist, the machine will also start to jump out of third gear under hard acceleration. This could finally result in extensive gearbox damage.

Another cause of this fault could be a loose kick starter ratchet nut or a loose clutch center nut. [O]

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

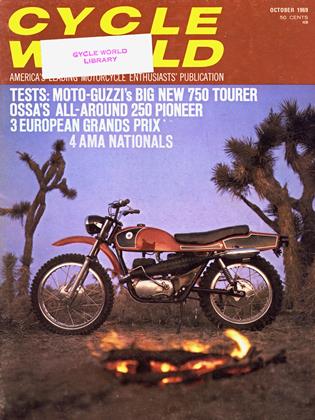

OCTOBER 1969 By Joe Parkhurst -

Departments

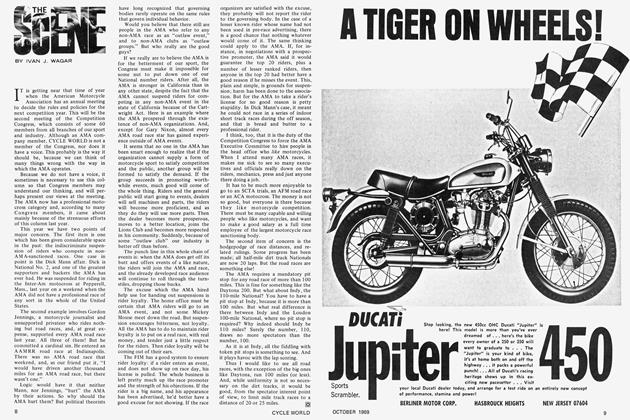

DepartmentsThe Scene

OCTOBER 1969 By Ivan J. Wagar -

Letters

LettersLetters

OCTOBER 1969 -

Competition

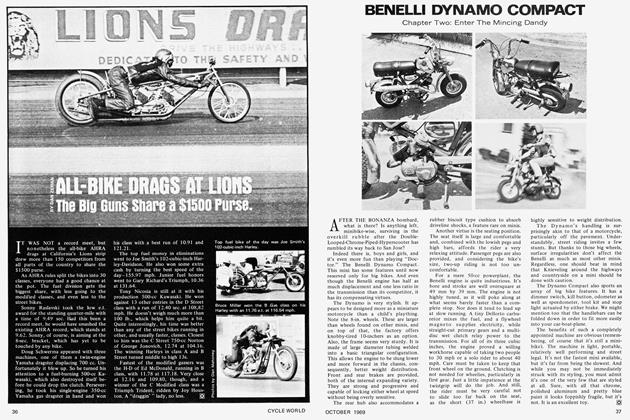

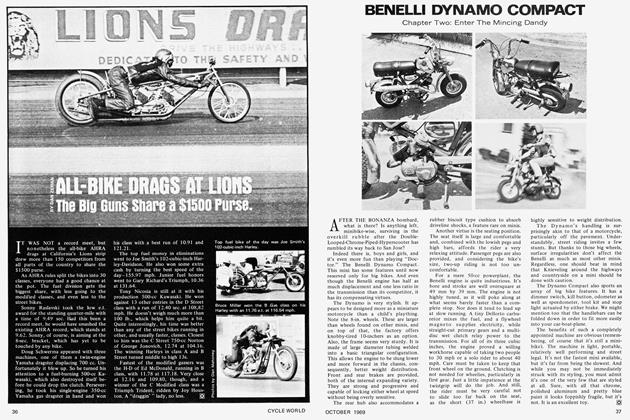

CompetitionAll-Bike Drags At Lions the Big Guns Share A $1500 Purse.

OCTOBER 1969 By Dan Zeman -

Tests

TestsBenelli Dynamo Compact

OCTOBER 1969 -

Features

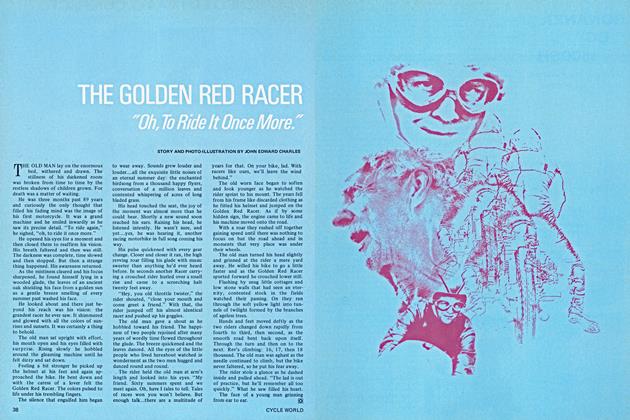

FeaturesThe Golden Red Racer

OCTOBER 1969 By John Edward Charles