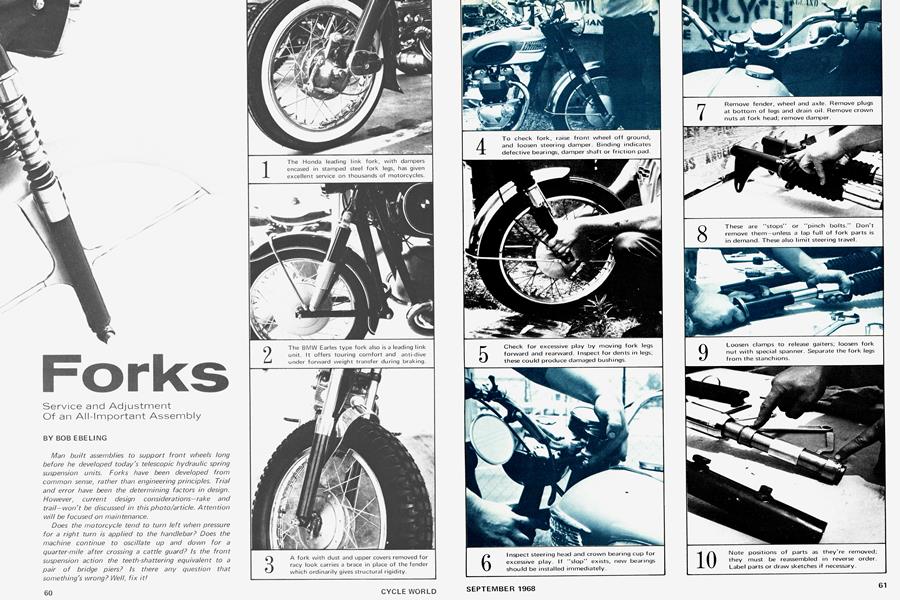

Forks

Service and Adjustment Of an All-Important Assembly

BOB EBELING

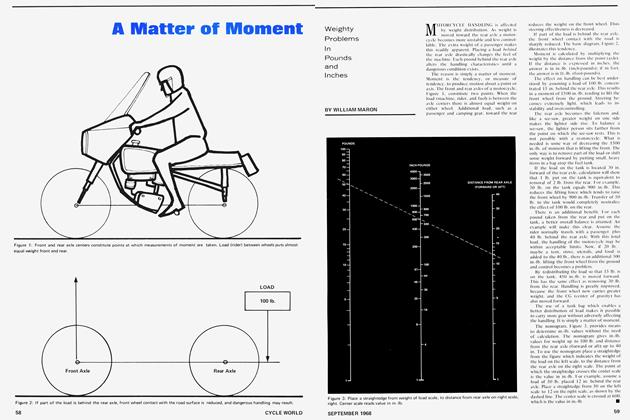

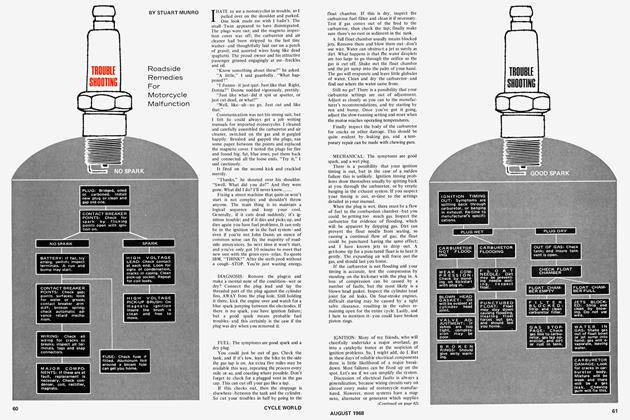

Man built assemblies to support front wheels long before he developed today's telescopic hydraulic spring suspension units. Forks have been developed from common sense, rather than engineering principles. Trial and error have been the determining factors in design. However, current design considerations—rake and trail—won't be discussed in this photo/article. Attention will be focused on maintenance.

Does the motorcycle tend to turn left when pressure for a right turn is applied to the handlebar? Does the machine continue to oscillate up and down for a quarter-mile after crossing a cattle guard? Is the front suspension action the teeth-shattering equivalent to a pair of bridge piers? Is there any question that something's wrong? Well, fix it!

That's just about it. Once the fork assembly is fitted to the motorcycle again, it is good practice to bounce the front end violently with stanchion pinch bolts slackened. This enables the legs to align themselves in the fork crowns. Be sure the damp bolts have been fully re-tightened before the machine is operated.

If seals have been renewed, if broken or damaged parts have been carefully replaced, and if the fork unit has been reassembled and remounted in proper order, the fix should be complete, the fork as good as new, the handling better than ever.

Fork service could only be encompassed in a very large book, thus this photo/story is designed to serve only as a guide. Telescopic forks from different manufacturers vary to some degree, and offer some individual problems. However, the basic principles of design, maintenance and repair remain identical.

Once again, check carefully for binding or any restriction of free fork and/or steering movement; replace oil seals; change the damping oil at 10,000 miles or less. Have a smooth ride.