Crash Program

The Search for the Super/Safe Motorcycle

JOSEPH BLOGGS

(CYCLE WORLD presents this feature to inform its readers. The magazine does not endorse, or take a position for or against any of the findings or views of the research team at Birmingham University which are reported herewith. - Ed.)

EACH YEAR road accident figures climb even higher, and with them the individual rider's chance of being injured. In an effort to reduce the total number of accidents and to minimize the injuries received during an accident, the University of Birmingham, England, has been working toward designing and building a new, safer motorcycle.

It's a little odd to find niversity rooms stacked with spare motorcycle parts, but this one even has one wall covered with a largerthan-life photograph of MV-mounted Agostini and a pair of ex-works, desmodromic Ducati racers lying under dust sheets!

The team which is making an investigation of the possibilities of building safer machines is headed by Dr. Peter Bothwell, who, as both a motorcycle enthusiast and a doctor of medicine, is well qualified for the work necessary.

In order to design a motorcycle which would be safer for its rider than existing machines, it first is necessary to study the causes and types of injuries which motorcyclists most frequently suffer. The mechanics of automobile and motorcycle crashes are similar. In both cases a moving vehicle is rapidly decelerated. The momentum of the driver, passenger or rider causes him to continue in the original direction unless there are appropriate restraints.

Retention and adequate padding pay dividends for the car driver and occupants, but for the motorcyclist this protection is almost nonexistent.

The driver and passengers in an automobile are restrained from hitting the insides of the vehicle by seat belts and/or shoulder harnesses, and it is this packaging which protects them from severe injury. It is a little odd, then, that while automobile driver and passengers are restrained for safety, many people firmly believe that a motorcyclist should be thrown clear of his machine if he is to survive—all this with only a safety helmet to absorb the impact!

As the largest percentage of injuries to riders are head injuries, it is more than conceivable that this risk would be lessened if the rider were to stay on his machine. The risk of his being thrown and striking any of the road furniture is reduced. While the head would therefore be better protected this way, some means of saving the legs, arms and hands from damage also would be necessary.

In any accident there are three time-phases: the preliminary phase, in which the condition of the machine, its placing on the highway and the experience of the rider play a great part; the crash phase, which takes place from the time of the impact until the cessation of motion of both the rider and machine; and the post-accident phase.

From the time an accident becomes likely until it becomes inevitable, there are a host of factors which can and do influence the event. There are two things which can be done to improve things which take place in this phase. First, the rider himself must be correctly trained. Second, the machine must be as controllable as possible. The latter is one area being investigated by Birmingham University.

There is a point in time when an accident becomes inevitable in certain situations. From this point to the actual impact the time gap varies from 1.5 to 0.25 sec. During the impact, the factors which affect the outcome already have been decided. These are: design of the machine, protective equipment being

worn by the rider, and whether the rider remains on his machine. This is the second area of investigation—to produce a machine which will cause as little injury as possible to its rider under all circumstances.

The post-accident phase is comprised of ambulance facilities, and hospital treatment, which have no bearing on the cause or type of accident, or on avoidance of the mishap.

There are, then, two main areas for experiment. The first is to design a machine which is less likely to permit its rider to encounter a dangerous situation. The second is to shape the machine so that it will either protect its rider, or at least help to reduce the injuries to him. In both these fields, Dr. Bothwell is demonstrating amazing success.

As some cf the most advanced and important experiments have produced results which are at this moment being patented, only general descriptions can be given. But as progress, like justice, must be seen to be done, this description should bring some comfort to those who believe the motorcycle industry has adopted the "safety-doesn't-sell" idea.

In order to make a motorcycle safer to ride, Dr. Bothwell has worked on three major points. These are: non-lock braking systems, two-wheel drive, and hub steering.

All these can be worked into one machine (plus some extra personal safety equipment) to make a remarkable motorcycle. The nonlock braking system now is widely used on the majority of large aircraft to prevent skidding or tire blow-outs while landing, both of which would be disastrous to an aircraft. Many aircraft use the Maxaret anti-lock system. This can be developed for use on a motorcycle to make braking in the wet and dry a less hazardous business. Imagine also what an advantage this could be for racing-a rider can tear into a bend, take a huge fistful of brake with the knowledge that it just cannot lock that front wheel! Chances of a front wheel skid would virtually disappear.

The theory of hub steering for motorcycles is fairly well known, but Dr. Bothwell considers that no future machine can be called safe unless built with hub steering. Present steering geometry leaves the front wheel and hub with too little support and creates a center of gravity which is too high. In addition, Dr. Bothwell's impressive advancement, two-wheel drive, could not be applied to a machine which does not have hub steering.

At present, all motorcycles are rear wheel driven. Shaft or chain drive makes little difference. The rear wheel takes all the drive and has about 80 percent of the road grip. This is nonsense, considering that the steering wheel (the front) has virtually no grip of its own on the road surface.

Looking again to the automobile world, where greater profits have allowed increased experimentation and investigation, one of the safest and most controllable cars on the road is the British Jensen. This car utilizes fourwheel drive.

Taking this car as his example, Dr. Bothwell has worked out a system, which would have as its basis a limited-slip differential, taking the drive from the clutch and delivering it to rear and front wheels. The exact mechanics of how this is done must remain secret for the time being, but they are fairly simple. The front wheel drive design also makes provision for a non-lock, disc brake to be used and, of course, hub steering.

When asked if these improvements would, when put into production, make present tire designs obsolete, Dr. Bothwell replied that he believes existing designs will, in fact, be shown to be even better than already realized. In effect, his improvements will allow existing tires to meet their full potential.

Although details of the two-wheel drive system cannot be disclosed, benefits which will result from it are obvious. Tire wear will be evened out as the power from the engine will be proportioned, probably with about 60 percent to the rear and 40 percent to the front. If road conditions change (as when the machine strikes a wet patch), the power would be transferred from one wheel to another so that each wheel had just the right amount of power, i.e., the maximum that it could transfer to the road. Riding in the wet and cornering would become far safer. Again, the racing rider certainly would benefit as he would have increased road grip which in turn would allow faster cornering.

Even riding the most controllable motorcycle in the world, it will be possible for the rider to encounter a situation in which an accident will depend on many things, but few of these are controllable. Resulting injuries, if any, however, can be reduced in number and severity by careful planning.

It is necessary to look at the types of injuries suffered by motorcyclists before an attempt can be made to produce something which will reduce them. Research has shown that there are two basic types of injury. One is caused by a minor or sliding accident, the other by a major or collision accident.

The first is most common. Though generally less severe than the latter type, it is in this category that most improvements can be made.

As a rider is not attached to his machine, he will tend to leave it even under the slightest impact. He may be thrown over the handlebars or he may leave the machine sideways, but both of these cases will involve parts of his body coming into contact with parts of the motorcycle.

To see just how potentially dangerous an ordinary motorcycle is, one can take a coat, hold it like a bullfighter's cape and drape it along and then across a machine. The handlebars, control levers, kickstarter and other parts stick into it. Ideally, a person should be able to be keelhauled around a motorcycle without any part of him being caught on projecting hardware. This is almost impossible with all production motorcycles in existence!

A bike must be smoothed out if the rider is not to suffer from these projections which cause some terrible injuries-injuries which could be avoided.

Dr. Bothwell claims that of all bikes he has studied, American police motorcycles are by far the most dangerous to their riders. There are many examples of gross neglect of safety by manufacturers on many modern machines-the gasoline tank luggage grid on a certain current motorcycle is extremely dangerous and has emasculated riders who have been unfortunate enough to be thrown over the tank and handlebars of their machines.

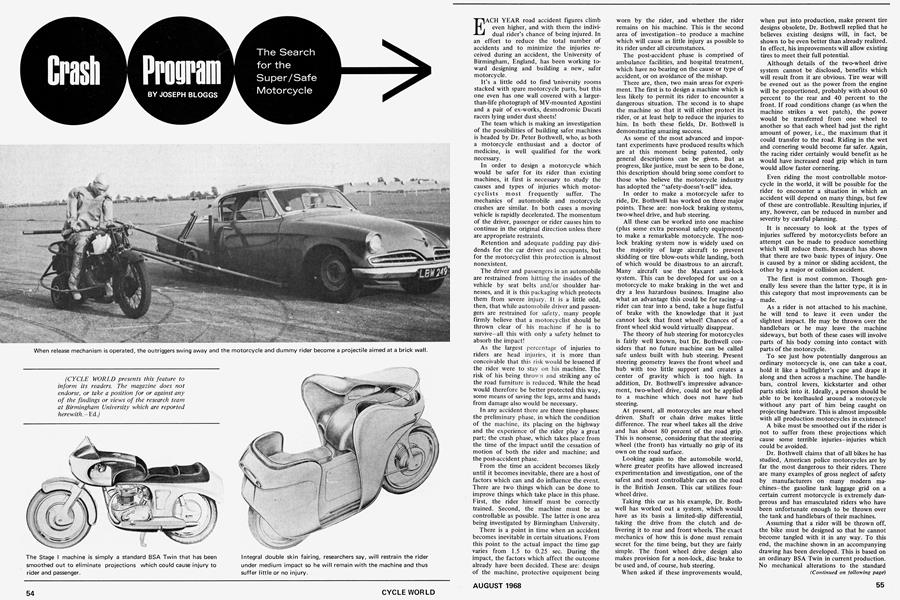

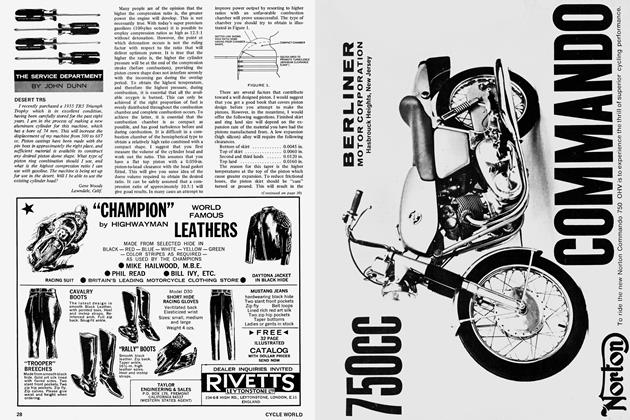

Assuming that a rider will be thrown off, the bike must be designed so that he cannot become tangled with it in any way. To this end, the machine shown in an accompanying drawing has been developed. This is based on an ordinary BSA Twin in current production. No mechanical alterations to the standard (Continued on following page) machine have been made.

The design shows that a great deal of safety can be built into existing machines almost immediately, so there is no excuse for manufacturers to delay. This machine, the "Stage I Machine," is quite free from projections. The rider can pass over the bike without injury. The fuel tank is fitted with a thick rubber covering which protects the groin from impact and shields the petrol filler cap. All instruments are deeply cowled in rubber, while the screen is made of a clear, shatterresistant plastic to avoid facial lacerations. In any case, the screen can be easily knocked out of place by a light blow from the rear.

In many accidents, the rider's legs, feet and knees suffer badly from striking the handlebars or being trapped by the bars as they turn against the fuel tank.

By using short handlebars (similar to clipons), which are recessed into the fuel tank, this type of injury can be avoided. The shaping of the seat into the tank also is designed to deflect the legs outward slightly to clear the handlebars.

As the gear lever, rear brake pedal, kick starter and sub-frame cause a large percentage of injuries to the legs and feet (especially when the rider slides along with one leg trapped underneath the machine), all these have been shielded and smoothed over. Thick rubber coverings have been placed over the silencers and exhaust pipes which carry the controls and also help prevent burns.

The gear lever is a rocking heel-and-toe type, buried beneath the rubber shroud with a thin rubber patch to allow operation by foot.

All control cables are carried internally to prevent their snagging a rider. All surfaces are rounded. No nuts project from the bodywork

and both front and rear fenders are smooth with return angles. This also cuts down the injuries to pedestrians who figure prominently in motorcycle accidents. In England, the front number plate is, at present, carried like a blade along the front fender-this causes terrible damage to pedestrians and is removed.

All these are really just modifications to a standard motorcycle, but at least they could be put into production fairly simply. Sales of machines should not be affected as the end product maintains a sporty appearance.

It is understandable that manufacturers would not wish to go to extremes to build a rubber box on wheels as motorcyclists are not, generally, the type who desire to be protected and fussed over. Even so, they are entitled to a fair degree of safety, and this must not be ignored for the attraction of increased sales.

Injuries in the second category are the most severe and result in severe head injury, broken limbs and internal bleeding. Dr. Bothwell hasn't yet managed to come up with a design which will allow the rider of a machine to smash into a brick wall from 100 mph and step out smiling. This sort of accident will do the rider little good however well he is protected!

There are some ways, however, that a rider may be protected even when he is involved in a fairly severe collision, though not a head-on smashup. Take a glancing blow for example-a rider goes a little too close to a parked car which suddenly pulls out while he is alongside. The rider normally would go sliding down the street on his back while his bike slides off elsewhere. Now, as long as that rider has a good safety helmet, thick protective clothing and isn't run over by a vehicle

coming the opposite way, he stands a good chance of getting off lightly-but it's a large chance to take.

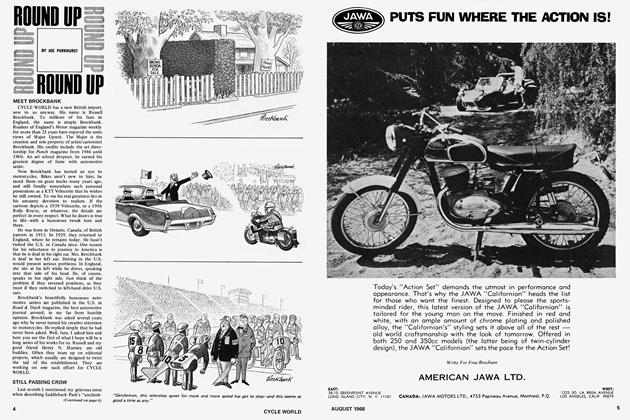

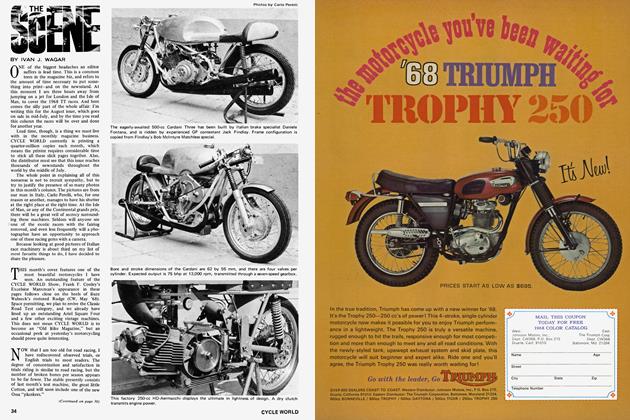

A design has taken shape in Birmingham University for a machine with an integral double-skin fairing which would restrain the rider so that under medium impact he will stay with his machine (as in the accident described) and will suffer little or no injury!

This fairing design has gone a lot farther than the drawing board, as it already is under test on a track in England. With this fairing, the rider can move around the machine quite freely, but is protected by it. It would be possible for the bike to slide along the street at almost any speed and, as long as the rider hung onto the handlebars, he would escape all injury. In addition, the fairing still looks right for conventional minds.

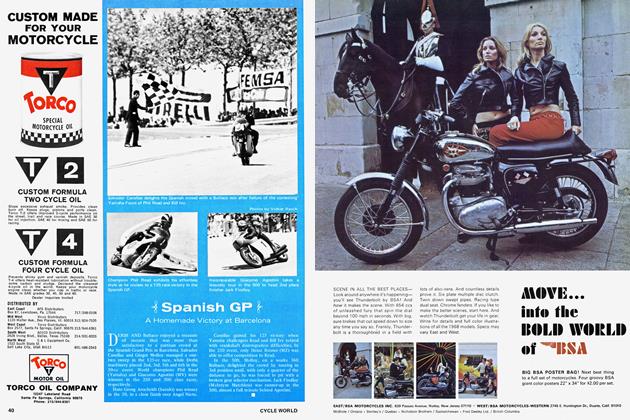

In the case of the rider actually being thrown, a new safety helmet design has been developed by the university group, and will go into production soon. It has the same styling of a full coverage helmet, but differs in its basic structure.

Two fiberglass shells are used, an inner and an outer. To the inner surface of the inner shell is attached a layer of honeycomb material made of stiff linen, but extremely tough. A small gap is left between this honeycomb and the upper shell. Into this gap is pumped polyurethane. This flows into all the holes of the honeycomb and finally makes up a layer of its own by filling the gap between the upper shell and the honeycomb, thus making a four-layer construction. This is so strong in the finished product that the wheel of a light car was lowered onto one of these helmets at its weakest point (which is across the temples), but failed to distort it! Instead of having the helmet straps and clips inside as with conventional designs, the long, single chinstrap passes under the chin and clicks into place between the two main shells. This insures that no part of the fastening mechanism can touch the face.

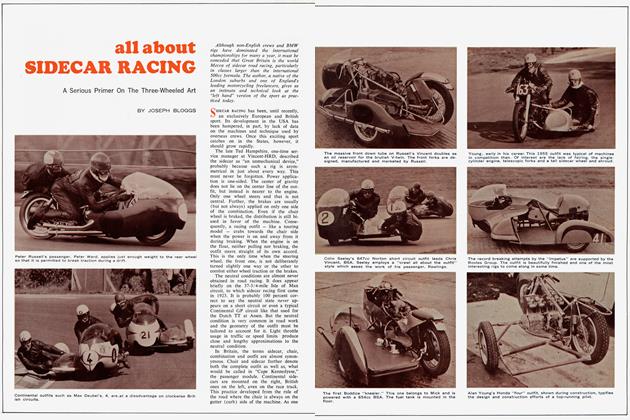

The fairing referred to is called "Stage II" by Dr. Bothwell. He's working on a "Stage III" machine which still is in quite early stages of development. Drawings show the basic idea, however.

Dr. Bothwell believes that to produce a really safe two-wheeled machine, the conventional configuration must be discarded in favor of one which has an extremely low center of gravity. In addition, both the rider and his passenger must be fully enclosed and secured into their seats—"packaged" just like the automobile driver. In this sense, the machine no longer is similar to any motorcycle, or to anything!

To stabilize such a machine is no problem; two systems are possible. The idea of sticking one's feet through openings or flaps is not considered, as most people would reject itthey would feel ridiculous and it carries a certain amount of injury risk apart from any synchronization problems which would occur.

The two systems are (1) an automatic, hydraulically operated pair of retractable rubber rollers, the exact design of which has already been worked out and, (2) a gyro. This is far more practical than it sounds. Dr. Bothwell is quite convinced that it could be easily and cheaply carried out.

On top of all this, weird and wonderful as it may seem, Dr. Bothwell also has been working on the relationship of external vehicle coloring to safety, but that's another story. ■