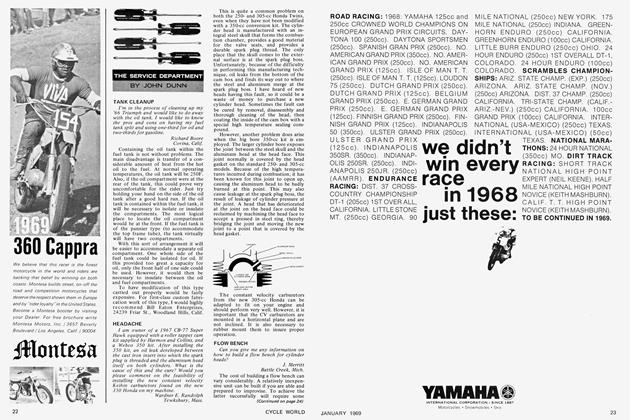

THE SERVICE DEPARTMENT

JOHN DUNN

ANNOYING, BUT AMIABLE

My Honda CL 77 scrambler has four annoying characteristics which detract from its otherwise amiable nature. It exhibits wheel wobble at high speed, eats spark plugs, vibrates fiercely at certain speeds, and is terrifically hard to start in cold weather.

The wheel wobble only begins above 60 mph, but at the most embarrassing moments, like when passing. It is initiated by a slight jar from the rcmd surface and cannot be stopped without slowing to below 50 mph, and applying the front brake hard, i have checked bearings, tire pressure, wheel alignment, and so forth. At first, the wobble begins with the whole front wheel and fork assembly (including handlebars), and, as it becomes progressively worse, the rear end starts shaking back and forth uncontrollably. Any weight (a passenger) on the rear of the seat accentuates the wobble. Plugs only last approximately 1500 miles. My dealer believes this to be very short life. The bike is always kept at top tune (factory speed), and I’ve tried both 9s and 1 Os. The 9s burn up slightly faster, but the I Os are too cold for much around-town driving. The. plugs seem to break down inside the porcelain insulator. I've used many different sets and brands from different sources, so I don 7 believe this is a cause. The pipes are not overly yellowed, so I believe the engine is not overheating, only around the plug seat.

In our New Jersey cold (below 32 F) weather winters, my bike just doesn't want to start. After using many techniques of my own invention to start the machine, I took my dealer’s advice and tried full choke and only a fraction throttle. After one run-through with the key off, I hit the ignition, and as soon as it fires, kill the choke and turn up full wick. Trouble is, this only works about one of three times, and if it doesn't catch on the first (or sometimes second) kick, I’m in for a good 50-60 additional kicks to clear the flooded cylinders and establish the proper mixture and temperament again.

From about 50-65 mph, and especially at 55 mph, there is a strong high-frequency vibration throughout the machine. Because the bike was bought ui early '6 7, it wasn't equipped with rubberized mountings, so I installed touring grips, rubber (scramblertype) footpegs, and designed and made rubber seat mountings all around. Although the newer machines also isolate the frame from the rear fender and tailpipe mountings, I believe this would not help much. I've used a high damping rubber compound and managed to decrease the vibration by some one-third to a half, but on any long trip it really gets to me after an hour or so. I 've had it suggested that I have the seat rolled and pleated. Any ideas on tuning, balancing, or isolation?

James Crampton Westfield, N.J.

The CL 77 Scrambler was designed as a dual purpose machine, a combination dirt and road bike. With this in mind, the factory made a compromise in the front end geometry. L-ess trail is employed to make the machine more maneuverable in the dirt. This in turn would make the machine more sensitive to irregularities at high speed. To combat the adverse high speed characteristics, the factory provided the bike with a hydraulic steering damper. 1 first advise that you remove the steering damper and check that it is working properly. It is noted that you have checked most of the things that could cause a high speed wobble, but I would advise that you check or recheck the following: Even if the steering head bearings are not loose, it is possible for them to be indented. If the bearing race is indented, the balls have a self-centering action. This can result in some very unpredictable reactions from the front end when encountering some relatively mild irregularity in the road surface. Check that the front wheel rim is true, not out of round, and is in good balance. If not, a very severe harmonic can present itself after a certain and usually consistent rotational speed is reached.

I am not certain from your comments whether the spark plugs are actually burning away or that the insulation is breaking down. You state that the plugs seem to breakdown in the porcelain insulator. This is usually caused by using a plug with a too cold heat range. The factory recommends a l)X he employed, but you are quoting 9s and 10s. Is it necessary to use these much colder plugs?

(Continued on pane 18)

To obtain easy starting under adverse conditions, it is essential that the engine is in first class tune. Check the condition and tune of the ignition system, making sure that both cylinders are properly timed. By careful adjustment of each contact breaker, it is possible to precisely time each cylinder individually. This does take a little patience and time, but is well worth the effort because sub-par performance on the 1X0 Honda Twins is often the result of the ignition timing being incorrectly set on one or both cylinders, l or optimum performance, including cold starts, it Is essential that the carburetors be in proper adjustment and that the throttle slides be synchronized that the slides start to open at the same time and obtain full throttle without one lagging behind the other. It is also very important that each cylinder pull evenly at idle. If the slides arc adjusted so that one cylinder is doing all the work while the other one is loafing, the engine will be extremely difficult to start. There is a very useful instrument on the market called a “Unisen,” which is a great aid for synchronizing the throttles at idle.

I think there would be very little gained by having the crankshaft balanced unless the vibration on your machine is worse than other models of the same vintage. The fact that the manufacturer resorted to the rubber mounts on later models indicates that the vibration is not caused by a balance problem. Trame design and method of mounting can have a very pronounced effect on conditions influencing vibration. I believe that isolating the exhaust system could be beneficial, as this would eliminate a source of vibration because the engine transmits vibration through the exhaust system to the frame.

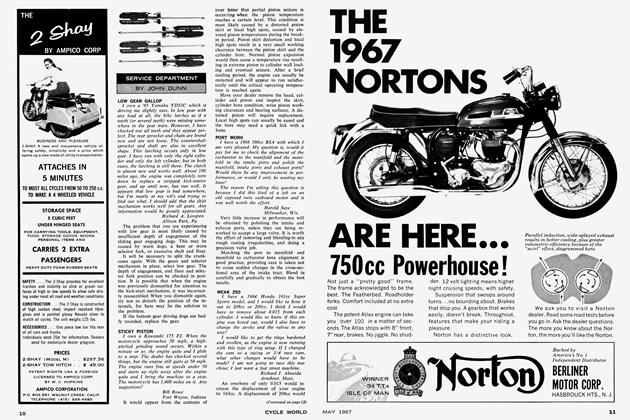

NORTON SPRINGS

/ ordered some valve springs for my 750-cc Norton. The mail order people sent me Terry ’s No. 501 valve springs which are used in the 500and 600-cc Norton Twin models. The proper spring for a Norton 750 ee is Terry’s No. 584. So. I wrote to the mail order house to make sure the Terry’s 50/ would fit my Norton. The outfit said it hadn 7 had any trouble with No. 50/ in the Norton 750.

The 50/ is a longer spring with one extra coil, but is made of very slightly lighter wire. Is it possible for the 501 spring to become coil-bound in the 750-cc Norton? Is there any advantage in using the 501 instead of the 584?

Raymond J. Rumbolz Kennewick. Wash.

1 do not know the difference between the No. 501 and the No. 5X4 Terry valve springs, but would suggest that you insist on No. 5X4 springs unless the factory recognizes the No. 501 as an alternative. 1 do not have a 750-cc Atlas workshop manual handy. Check with your local Norton dealer and find out what the correct set height of the No. 5X4 springs should be, and determine the spring pressure at this height. The set height is measured with the valve on its seat, and is the distance between the bottom spring seat and the top spring retainer. To obtain the correct set height, it may be necessary to place shims under the bottom of the spring.

To check the spring for coil bind, it will be necessary to know the compressed height of the spring and maximum valve lift measured at the valve. Put the spring in a vise and fully compress it, measuring the compressed length with a venier caliper or a micrometer. You will know the correct set height from the workshop manual. Subtract the full lift measurement taken at the valve from the set height, then subtract the compressed length from the answer. This will give you the amount of spring movement left before coil bind occurs. For example, if the set height is 1.750 in., the maximum valve lift is 0.500 in. and the compressed length is 1.125 in. The amount of movement before coil bind will be as follows. The 1.750 in. minus 0.500 in. equals 1.250 in.; then 1.250 in. minus 1.125 in. equals 0.125 in. A free movement of 0.075 in. should be treated as a minimum before coil bind.

(Continued on page 20)

If you know the poundage of the correct spring when installed at the correct set height, the No, 501 spring can be compared at the same height with a valve spring tester. If they arc both within 5 lb. at this height, and the 501 does not become coil bound, it is quite likely that it will work well as an alternative to the 584.

NOTHING'S PERFECT

/ have been riding motorcycles for the past 10 years, and have owned 12 machines of various types and sizes. I have yet to find the perfect motorcycle. After a lot of thought and deliberation 1 have come to the conclusion that it is impossible to obtain a machine "off the shelf" that will meet all my demands. 1 now intend to build a machine that will encompass all the good points of machines produced at the present time and in the not so distant past. Having studied this subject very closely, 1 have come to some very definite conclusions, but would very much like to have your suggestions on an ultimate machine for street and fast long distance touring activities. Do you think it is possible to construct the ideal machine?

Larry Berg Seattle, Wash.

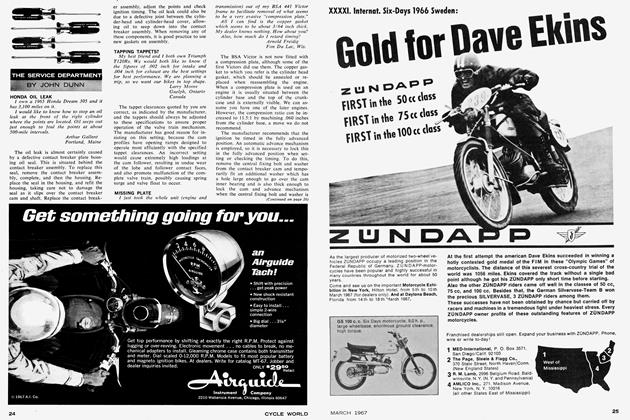

Is there such a thing as a perfect motorcycle, Larry? 1 am sure that many riders have had the same desire, including myself. I have owned a few motorcycles, and have ridden many more. Possibly the most stable and best handling machine that 1 can recollect was a racing Manx Norton, either 350 or 500. Norton came out with the Featherbed racing frame in 1949. It was a full cradle type frame with outboard supported pivot swinging arm rear suspension. The steering head was of sensible proportions and tied in rigidly to the main frame structure. The front fork was the famous Norton “Road Holder.” a fork that provided the optimum front end suspension. All the major racing factories operating today have employed frame designs of the same basic concept. In the 1950s, Norton introduced a street machine (the Dominator 88, a 500-cc Twin) that had a frame and suspension system almost identical to that employed on the Manx Norton.

If I were to build a good street bike, the first thing that I would obtain is cither a Manx or Norton street Featherbed frame. The next must is good brakes. It does not matter how well a bike performs and handles, it is a tragedy without good brakes. For truly quick stops, a first class front brake, and a rear brake that is progressive and that is capable of locking the rear wheel at near maximum applied pressure, are absolutely necessary. A Manx twin leading shoe front brake is hard to beat. However, if one is not available, an 88 or a 99 unit will do nearly as well, if set up properly. The latter also applies to the 88 or 99 rear brake.

There are several engine and transmission combinations that could be employed successfully in the Norton frame. I would personally use a unit construction Triumph 650-cc Bonneville engine. Taking everything into consideration, I find this to be a reasonable compromise. The 650 has good specific output, reasonable durability (not the best), a very good transmission and gear change. Also, installation would present very few problems.

f or riding position 1 would select a compromise between a full road racing position and the usual upright touring position. The handlebars, if mounted in the normal position. should be straight with little or no rise. I-or high speed touring and good control there should be a little forward rider lean with some weight on the arms. At around 80 mph (considering the wind force on the rider’s body) the hands should rest just lightly on the bars. The footpegs and controls should be positioned to give maximum comfort and control. No discomfort should be experienced after two to three hours of hard racing. If leg cramps and backache occur, an adjustment in riding posture is indicated. A fairing also can reduce rider fatigue, particularly when long distance high speed runs arc contemplated. Good lighting is essential and must be within the law. However this should not present a problem as there are several good systems to choose from. Tire sizes play a major part in the handling characteristics of any machine. The general trend in the U.S. today is to fit the largest available tire. This is just plain stupidity as far as street conditions arc concerned. With the combination of machine previously mentioned I would have cither a 3.00 or a 3.25 maximum in the front, and a 3.25 or 3.50 maximum in the rear. All controls should be adjusted and positioned so they can easily be used.

My observations and suggestions in this answer are based on personal preferences, which I hope can be adapted at least in part by those who wish to get the most from motorcycling. ■