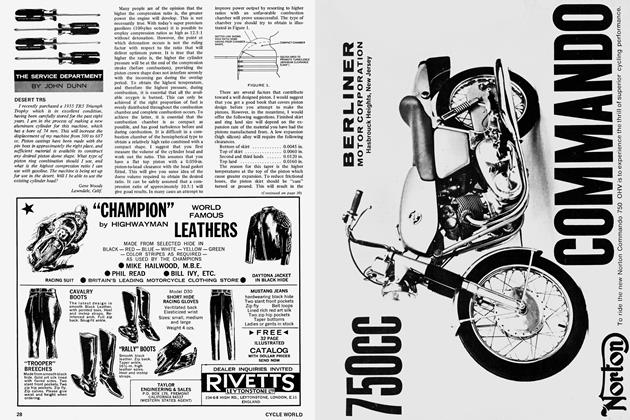

THE SERVICE DEPARTMENT

JOHN DUNN

DETUNING

I own a 1966 Yamaha YDS-3. Most fellows want modifications for more speed, but I would be happy if you could tell me how to detune my engine for more low speed torque. In the area in which I live, we do as much cowtrailing as road riding, and I find the bike not well suited for slow going in loose or sandy terrain. I have ridden a Yamaha YD-3 with single carburetor and find it has gobs of torque compared to my YDS-3; yet upon checking, I find the transmission gear ratios are the same (at least in first gear, which is the one I'm concerned with). Would it be practical to install YD-3 barrels and carburetor on my YDS-3, and are they directly interchangeable? I have tried various sprocket combinations, which help, but this really is not the answer.

Earl Jennings

Susanville, Calif.

The YD3 and YDS3 are equipped with entirely different engines. The YD3 has a bore and stroke of 54 x 54mm, where the YDS3 is 56 x 50mm. Due to the difference in stroke, it is not possible to exchange barrels and pistons without great difficulty. The torque characteristics of a two-cycle engine are, to a very great extent, determined by the port timing. To detune an engine by altering the port timing is difficult, because this would require a process such as welding to reduce the height of the ports. However, a decrease in carburetor choke size could prove very beneficial and is well worth trying. The YD3 carburetor could be employed. It is a Mikuni VM20 SC and has a 20mm choke as opposed to the 24mm choke size normally used on the YDS3.

The YDS3 is equipped with 3.00 x 18 tires, both front and rear. Better handling would be obtained in soft sand if a 3.25 or 3.50 section tire were used. The larger section tire will result in a higher gear ratio, so it may be necessary to drop the present ratio.

ALL ABOUT OIL

1 own a '66 Ducati 250cc Monza. With only 7,000 miles on it, the bearings in the transmission and on the crankshaft blew. The piston seized and had to be replaced. The dealer didn’t even find some of the balls from the bearings. One of the bearings seized on the crankshaft. At about 6,000 miles, the copper tip of the exhaust valve tappet disintegrated, so I filed it down and am running on the steel stub. The dealers say this won't rob power or wear excessively. Do you agree?

I would like some advice on oil and heat. The manual recommends ESSO Extra Motor Oil 20W, 30W, 40W, or Racer 40. Does this mean that any one of four oils is satisfactory? Which AMOCO or Standard oil would compare to this ESSO? I have been using Aero-Shell 50 non-detergent except for the CASTROL during break-in. I change oil about every 900 miles. Another dealer where I inquired recently, recommends 30 light-detergent, so I am getting slightly confused. 1 have never noticed that the bike was running hot. Before riding, I have always warmed up the bike. Could one of the head temperature gauges or an oil light be installed?

The manual states that the oil capacity is .634 U.S. gallon or just over five pints. However, two dealers that I know always use two quarts, and that is what 1 have been using. Do you know what the importer suggests?

John Schlick

Paynesville, Minn.

There are several factors that could have caused premature failure of the engine. What happened to the fragments of the shattered copper pad to which you referred? If these were not retrieved and were allowed to pass through the engine, it is not surprising the bearings were severely damaged. Contrary to your dealer’s advice, I would suggest that you replace the defective part, in keeping with the manufacturer’s original design considerations.

The grades of oil referred to do not only apply to ESSO, but to all lubricating oil manufacturers that use the SAE standards for identifying the viscosity rating of their product at a given temperature. If you prefer to use a multi-viscosity oil, I would suggest that you use SAE 20W-30 in the winter and SAE 20W-40 in the summer. If not, use SAE 30 in winter and SAE 40 in summer. The figures only give an indication of the viscosity of the oil and unfortunately do not give any other information. When a number ends with the prefix “W,” this indicates that the oil has a certain viscosity rating at 0°F. When shown without the “W,” this indicates the rating at 240°F. In your letter you mention the use of Castrol during the break-in period. However, you did not mention whether it was a mineral or a vegetable-type oil. If it was a vegetable oil it would be necessary to flush the lubrication system to make sure that all traces had been removed before changing to a mineral oil. If this is not done, oil passage blockage may occur, thereby cutting off or restricting the feed to some vital point. If a vegetable oil, such as Castrol R, has been used, it is good practice to completely dismantle the engine and thoroughly clean all the components and oil ways with alcohol. This will naturally include the oil tank and pipe work if an external tank is employed.

With respect to oil capacity, your machine is fitted with a graduated dip stick that indicates the correct level, when it is just placed in the filler hole and not screwed in.

An oil temperature gauge would be of more value than an instrument that indicates cylinder-head temperatures. It may be possible to locate the oil temperature pick-up in the sump drain plug.

(Continued on page 22)

TRIMAHA

At present I have a ’65 Yamaha YDS-3. I have become rather disgusted with the amount of service required to keep the engine in even passable tune. In the interests of better pulling and cruising power, I would like to install a larger displacement engine.

I realize the easiest solution would be to install the 305cc YM-l engine, but 1 am discouraged with two-cycle engines in general. What are the possibilities of substituting either a 500cc Triumph or BSA engine in the Yamaha frame? 1 am aware of some of the problems l would run into, such as reversing the rear wheel, mating the electrical systems, routing an exhaust system and aligning the countershaft and rear wheel sprockets, not to mention the actual fitting of the engine to the frame.

Does the conversion sound possible and practical? Would the cost make the whole plan unwise?

Mark R. Nelson

Old Greenwich, Conn.

A 500cc unit construction Triumph engine in a YDS3 frame? I have not heard of anyone trying it, but it sounds interesting enough. The center of gravity would be higher and there would possibly be more weight on the rear wheel. With the present wheel base (only 51.9 inches) and the extra torque of the 500 engine, it may be difficult to keep the front end on the ground when it is turned on. This can be fine for doing wheelies, but can be a bit disconcerting when accelerating hard through a fast bend. However, the proof of the pudding is in the eating, and if things do get a bit hectic, the rear swinging arm can be lengthened a couple of inches to provide the necessary effect.

Yes, I would think, providing the engine will go in the frame without too much trouble, it is well worth trying. At least you would have something that many people are striving for today, something different. As far as economics are concerned, if you can get the right price for your Yamaha engine, there should not be a great deal of cost involved.

If anyone has already gone this route before, please let me know and I will pass the details on to Mr. Nelson. Also, if anyone is contemplating putting a 250 Yamaha in a late Triumph frame, say the word.

BREAK-IN GUIDE

What is the best way to break in a new or rebuilt motorcycle? Do you break it in the way you expect to drive it? Does a machine that is broken in fairly fast necessarily run fast?

Do motorcycles in general (and specifically 650cc and larger machines) have to be “babied” to last or can they be “bustedon” once in awhile?

Bob Smith New Orleans, La.

A motorcycle should be broken in progressively, with thorough maintenance and frequent oil changes. Most engine failures that occur within the first few thousand miles can be attributed to premature damage caused by lack of attention during the break-in period. No matter what method is employed to run in a machine, it is essential that all things are in proper adjustment and tune. During this period, a higher degree of heat is generated, due to friction, than would be experienced in a fully run-in engine. So, any malfunction caused by an incorrect adjustment would make matters worse, possibly increasing the operating temperature to an intolerable degree, resulting in the distortion of various components and the break-down of adequate lubrication, thereby causing permanent damage. All adjustments and settings should be maintained to the specifications recommended by the manufacturer. The need for proper adjustment does not only apply to the engine, but it is most important that the whole machine be correctly maintained.

Actual break-in is a matter of “feel,” combined with a little common sense and patience. It is not considered very good practice for a new machine to be broken in by a learner, due to his lack of experience. There is always good advice to be found in the rider’s manual supplied with each new machine, and it is well worthwhile digesting the contents of this book before using the machine, so that you will have a good understanding of the most important factors governing proper function and operation.

The first 200 miles should be carried out very carefully, with the engine being allowed to run freely without lugging. This can be achieved by making full use of the gearbox, which in turn helps to break in the gearbox internals and shift mechanism. During this relatively short period, the working parts will be wearing in and settling down, so it is important that all settings are checked and adjusted to the correct specifications. The oil will contain a high degree of foreign particles, so drain it (while the engine is hot) and replace it with the correct grade and quantity of new oil. During the next 1,000 miles or so, the speed of the machine should be progressively increased, until at the end of this period, providing the machine easily accepts it, full throttle is employed for short periods. Change the oil frequently during this period (approximately every 300 miles) and be sure that all things are in proper adjustment.

PUZZLER

ƒ own a 1965 Honda CB 77 Super Hawk that has the local shops stumped. It has been bored to 0.50mm oversize and has 0.018 ring end clearance. This clearance, I’ve been told, is excessive.

The machine will not hold an even speed above 4,300 rpm! 1 held it below

4.000 for 500 miles to seat in the rings. Going through the gears, it will easily tach

10.000 rpm, but at any steady rpm above 4,300, it loses all power after a mile or two and acts like it wants to seize. Close examination of the pistons, rings and sleeves gives no evidence of seizure. I have not heard of any similar happenings and would like to know if your experience can give me any light on the subject.

(Continued on page 24)

Robert G. Frisch Selma, Ala.

It is most unlikely that the trouble you are experiencing is due to the piston ring end gap. Although the 0.018-inch you quoted is a little on the wide side, it is still within the acceptable maximum tolerance of 0.024-inch recommended by Honda.

Yours is a difficult problem for me to assume an answer to without riding and visually inspecting the machine. There is no reason why an experienced mechanic cannot diagnose and rectify the cause.

The sensation of seizing is most likely due to the engine dying, caused by a carburetion or ignition malfunction under sustained part-throttle operating conditions. Make sure that you are using the correct grade of spark plug and that the carburetors are set and adjusted to the correct specifications, including the carburetor float level. Also, make sure that the fuel tank cap is properly vented. If sufficient air cannot get into the tank the rate of fuel flow to the carburetors will be restricted, and under sustained operation, will cause the level to drop in the float chambers. Try running the machine with the tank cap removed.

A spark plug that is too hot can sometimes have a peculiar effect, and the engine will die after a period of sustained running. When the engine is not up to full operating temperature it will function perfectly throughout the rev range for a short time, until the operating temperature rises to the critical temperature of the plug. In cases like this, after the engine has been allowed to cool, it will function perfectly again. Let me know what cures the problem, Robert; it may be of value to other readers.

AFTER THE FALL

In the spring of this year I purchased a new Yamaha YM-1 305cc motorcycle. I was very satisfied with the machine, especially its very good vibration-free cruising speed.

I purchased this particular make because it has a reputation for reliability, together with looks, speed, etc. Now, at 1,500 miles, my Yamaha is in pieces due to it freezing up at 70 mph on the freeway.

Some of the history is due here, so you can judge if what 1 did caused this. At 250 miles 1 had an accident with the bike which produced a dinged front fender, broken light, crushed oil tank, broken shift lever, and a few dings and dents which were negligible. 1 had it checked at 500 and 1,000 miles. After this, 1 fiddled with the carburetors, as the amp light was always on at idle of around 1,200. 1 set it up to 1,800 rpm. Now, on getting the cylinders and heads off after it froze up, 1 find that the left cylinder was much more severely scored than the right. Also, the plunger of the oil pump wasn’t going up and down. The left side wasn’t getting as much oil as the right by ratio of about two drops of oil for the left for every three drops to the right.

After this, I checked the timing and found it didn’t at all correspond to the service manual, which states that it should fire at 1.9 to 2.0mm. They were not firing until tdc.

The sparkplug 1 have been using is a B-7HZ NGK. What is the correct sparkplug for a Y Ml for city driving and what is correct for long distance driving? 1 use Castrol heavy duty 30 weight oil. It has been my experience that Castrol is an extremely good oil, but is it a good oil for this motorcycle?

Is it necessary to place the open ends of the rings so that they do not cross any of the porting in the cylinder?

1 have a fairing ordered for the Yamaha. After it’s in running condition again, 1 would like to raise the gearing. What would you recommend in the way of a sprocket, and what does a higher gearing do to my rpm?

Harold Klein East Detroit, Mich.

There are several adverse conditions mentioned in your letter that could have caused the piston seizure. Lack of lubrication caused by the improperly functioning oil pump would appear to be the main offender. Also, the retarded ignition timing would cause over-heating and possible seizure. Yamaha recommends an NGK B-8HN as standard and the hotter B-7HZ may have been unsuitable for high-speed freeway riding.

(Continued on page 26)

Piston ring end gap position is determined by a small peg that is fitted in each ring groove to prevent the ring from rotating. It is still very necessary to check the ring end gap before fitting.

To my knowledge there should be no problems when using a Castrol SAE 30 MS oil in your engine.

Regarding the higher ratio rear sprocket to be used with a fairing, I would suggest that the sprocket be replaced with one having two less teeth. A similar effect will be obtained by using a gearbox final drive output sprocket with one more tooth than the standard one. The effect of using a higher gear ratio will result in a lower engine speed at the same road speed, providing the engine can pull the higher gear.

EXPOSED CLUTCHES

Why doesn’t the clutch hub bearing on Triumphs that are run with open cases fail after extended running? 1 can see why this bearing wouldn’t be affected in V4 mile drag racing, but why doesn’t it seize up from friction when used at road races and speed trials? (One example is the 1949 GP Triumph shown on page 60 of the March, 1966, issue of CW.) Does the hub turn so slowly that the bearing won’t seize except after many miles of running, or is there some special way that this bearing can be lubricated even in a dry clutch?

Assuming this bearing does require some form of lubrication, how many miles could be covered if this bearing were covered with heavy grease before it would require lubrication again?

Randall Johnson Hollywood, Fla.

A roller bearing will operate satisfactorily with a minimum of lubrication. This fact is demonstrated by the scanty lubrication most two-stroke big-end bearings receive. Roller bearings do not require a high-pressure feed system which is most necessary where plain bearings are concerned. Many machines, prior to WW II, operated with dry (open or partially open) primary drives and clutches. The clutch hub bearing is only operative when the clutch is disengaged. The usual method was to pack the bearing with grease. However, some clutch bearings on racing machines did derive some benefit from a dripfeed system of lubrication intended for the primary chain.

TOURING S-90

Could you please suggest a few tips that I could use to increase the horsepower of my Honda S-90?

1 do a lot of long distance touring with my bike and I would like a little more power for toting my girl friend or lugging heavy camping equipment. 1 have already changed engine sprockets from 15 to 14 teeth. This reduced top speed to 55 to 60, raised the revs and helped lugging power.

1 have heard of high compression pistons, but I am afraid to act without advice. If a higher compression piston is used, how high should it be, and will it affect the heat range of my spark plug, or should 1 use a cooler plug?

What manufacturer do you recommend if a different cam is advised?

Bob Covell

Carleton Place, Out.

When extra torque (lugging power) is required, there is no substitute for capacity (cubic inches). The S-90 Honda is equipped with a very efficient engine which has a high specific output for its size. To suit your needs you really require a larger capacity machine. No matter what modifications are made to your machine, it is doubtful you will end up with the type of machine that will fully suit the intended application. However, if you persist in modifying the S-90. I would suggest that the following mild modifications are carried out. All these suggestions are made in an effort to improve the overall performance throughout the entire speed range, without affecting the durability.

There are several big bore kits on the market for the S-90, and, providing that this method of increasing capacity is not overdone, it will have a beneficial effect on torque throughout the speed range. Even an increase of one mm on the bore size will increase the capacity from 89.6cc to 92cc.

Increasing the compression ratio will also increase the output throughout the speed range, providing that the combustion space promotes good flame travel and that the piston dome does not interfere with the intake valve flow, thereby adversely affecting good volumetric efficiency (breathing) and fuel droplet distribution within the cylinder. An increase to approximately 9.5:1 is suggested. Make sure that there is adequate piston crown to cylinder head and valve to piston clearance, checking the latter right through the overlap period. The higher compression ratio will cause higher combustion temperatures, so it will be necessary to use a colder spark plug.

Combined with the modifications mentioned, most of the high performance camshafts on the market will result in an increase of mid-range and top-end torque. Webco, of Venice, California, manufacture a good cam for this machine. However, to obtain the best performance, it is recommended that you also use the high frequency valve springs also supplied by this company.

The success of these or any other modifications will depend entirely on attention to detail and good workmanship, so if you are not capable of doing a first-class job yourself, have the work carried out by a known expert. H