A LOOK INSIDE THE MANX ENGINE

GORDON JENNINGS

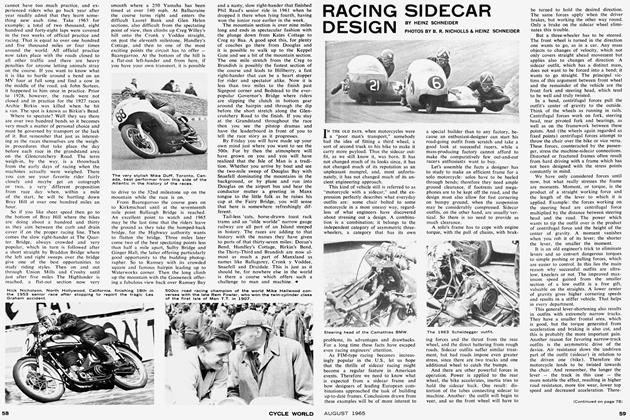

IN A SENSE, the design and development of Norton's famous "Manx" engine is a study in human personalities. The engine was designed, in 1927, by one Walter Moore, who was then Norton's chief design engineer. He did his work well: the engine, a long-stroke, overhead camshaft single, was reliable and produced enough power to bring forth a Norton win that year at the Isle of Man. Even in 1927, of course, the Norton racing engine was not exactly a daring design, but it was a very competent piece of work, and that is what one needs to get the job done more often than not. However, the real story of the Norton racing single begins where Moore stopped: with the entrance of the immortal Joe Craig on the scene. This determined Irishman never departed much from the original design, but he breathed life into it for years after it should have been a lost cause. It was, obviously, a losing battle in the long run, but an interesting one for all of that.

Joe Craig assumed responsibility for Norton's racing efforts in 1927, and by 1938 he had brought the big single along to the form we know today. Originally the engine had a single overhead camshaft; in 1938 a few more gears were added up in the cam box and it became a "doubleknocker." The 79mm x 100mm bore and stroke dimensions were unchanged, as were the bevel-gears and tower-shaft drive to the cambox. Later, the bore and stroke would be altered, with additional detail modifications here and there, but Joe Craig apparently felt that the basic design was all a race gaffer could ask.

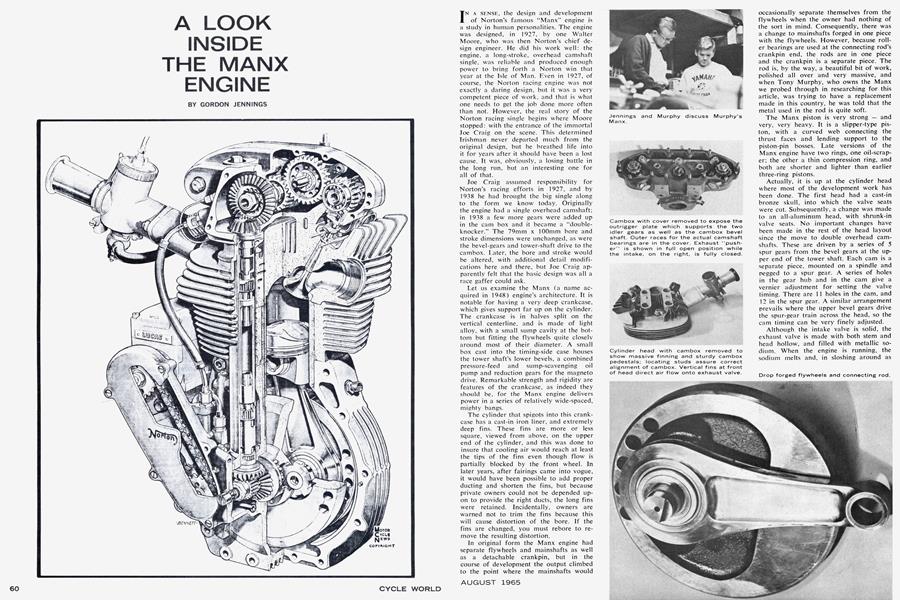

Let us examine the Manx (a name acquired in 1948) engine's architecture. It is notable for having a very deep crankcase, which gives support far up on the cylinder. The crankcase is in halves split on the vertical centerline, and is made of light alloy, with a small sump cavity at the bottom but fitting the flywheels quite closely around most of their diameter. A small box cast into the timing-side case houses the tower shaft's lower bevels, a combined pressure-feed and sump-scavenging oil pump and reduction gears for the magneto drive. Remarkable strength and rigidity are features of the crankcase, as indeed they should be, for the Manx engine delivers power in a series of relatively wide-spaced, mighty bangs.

The cylinder that spigots into this crankcase has a cast-in iron liner, and extremely deep fins. These fins are more or less square, viewed from above, on the upper end of the cylinder, and this was done to insure that cooling air would reach at least the tips of the fins even though flow is partially blocked by the front wheel. In later years, after fairings came into vogue, it would have been possible to add proper ducting and shorten the fins, but because private owners could not be depended upon to provide the right ducts, the long fins were retained. Incidentally, owners are warned not to trim the fins because this will cause distortion of the bore. If the fins are changed, you must rebore to remove the resulting distortion.

In original form the Manx engine had separate flywheels and mainshafts as well as a detachable crankpin, but in the course of development the output climbed to the point where the mainshafts would occasionally separate themselves from the flywheels when the owner had nothing of the sort in mind. Consequently, there was a change to mainshafts forged in one piece with the flywheels. However, because roller bearings are used at the connecting rod's crankpin end, the rods are in one piece and the crankpin is a separate piece. The rod is, by the way, a beautiful bit of work, polished all over and very massive, and when Tony Murphy, who owns the Manx we probed through in researching for this article, was trying to have a replacement made in this country, he was told that the metal used in the rod is quite soft.

The Manx piston is very strong — and very, very heavy. It is a slipper-type piston, with a curved web connecting the thrust faces and lending support to the piston-pin bosses. Late versions of the Manx engine have two rings, one oil-scraper; the other a thin compression ring, and both are shorter and lighter than earlier three-ring pistons.

Actually, it is up at the cylinder head where most of the development work has been done. The first head had a cast-in bronze skull, into which the valve seats were cut. Subsequently, a change was made to an all-aluminum head, with shrunk-in valve seats. No important changes have been made in the rest of the head layout since the move to double overhead camshafts. These are driven by a series of 5 spur gears from the bevel gears at the upper end of the tower shaft. Each cam is a separate piece, mounted on a spindle and pegged to a spur gear. A series of holes in the gear hub and in the cam give a vernier adjustment for setting the valve timing. There are 11 holes in the cam, and 12 in the spur gear. A similar arrangement prevails where the upper bevel gears drive the spur-gear train across the head, so the cam timing can be very finely adjusted.

Although the intake valve is solid, the exhaust valve is made with both stem and head hollow, and filled with metallic sodium. When the engine is running, the sodium melts and, in sloshing around as the valve moves, transfers heat from the head up to the stem and from there into the guide and the cylinder head. This is imnortant. In such a big combustion chamber, detonation is hard to suppress, and the hot-spot created by an overhot valve would initiate a great fit of pinging. In this connection, we could point out that even though the Manx engine has a nominally hemispherical combustion chamber, there are flats and convolutions in the piston and combustion chamber that form large squish areas and have the effect of making the combustion area more compact. These efforts toward combustion control have paid dividends, for in the latest form of the engine, the compression ratio is 11:1 and there is no detonation when using a premium-grade gasoline.

In normal service, and apart from the damage that can be caused by over-revving, the weakest point in the Manx engine is its valve springs. These are of the hairpin varietv, and are mounted completely exposed. True-blue Manx mechanics will alwavs have a special pair of pliers to use in replacing these springs without lifting the cambox. The springs are, however, not exposed for easy replacement. Rather, it is to allow cooling air to reach the hardworked springs. One might wonder how the valve guides get oil, with so much empty space around their upper ends. This is provided for by small pipes, which feed oil directlv into the guides. Another problem is that of lubricating the somewhat exposed tappets, which have their lower ends hanging down in the air. In this case, the oil comes from the cam box, and seeps past the cylindrical tappet. The tappet is virtually a press-fit in the tappet bore when the engine is cold, but loosens at running temperature. No effort is made to catch oil that gets past the tappet — and plenty does. It simply runs down onto the valve stem and springs, and is carried away in the air stream. Experienced Manx types. Murphy tells us, warp plastic foam around the head to catch as much of this oil as possible, and that helps the situation somewhat. Even so, between the exposed tappets, and pressure-fed oil to exposed valve stems, the Manx engine flings a lot of oil about no matter what one does about it.

From the beginning of development of the Manx engine, plenty of attention was given to the "tuning" of intake and exhaust tract lengths, and it is this, as much as anything else, that accounts for the 50 bph extracted from the engine in its final form. Unfortunately, in pulling this single up to the 100 bhp/liter output level, it was necessary to tune a trifle too finely for comfort. The Manx engine is a monster of fussiness, always ready to drop "off the cam" if the revs get down a bit. In fact, there is such a fit of "megaphoning" at just about 3500 rpm that the engine will not pull any higher unless you pull in the clutch. The trick is to slip the clutch until you gather enough speed to let in the clutch fully and have more than 4500 rpm in hand. Actually, the usable speed range is from 5000 to 7500 rpm, and that is really not enough when you add the handicap of a 4-speed transmission.

Over the years, the Manx engine's piston stroke came down from the originala 100mm. or 3.94", to 3.38" in the last version sold to the public just before production on the model was suspended. There is evidence that Joe Craig did not like this short-stroke trend very much. In an interview, he stated that in his opinion, the lOOmm-stroke engine was really quite all right, as a lot of victories had been gained with it. However, the time came when even Joe Craig must have felt the pinch of the newer Italian "multis," for the racing Norton did undergo several reductions in stroke. More power must in the end come from more revolutions per minute, and as even in the "square" configuration, with a bore of 3.39" and the 3.38 stroke, piston speed was over 4000 feet per minute at the power peak of only 7200 rpm.

Officially, the factory withdrew from racing in 1956, but there was a lot going on behind the scenes. For one thing, there was a water-cooled "four" that actually made it into partially-finished castings. But, most of the work was directed at making the old single do the job. Stroke-shortening schemes were tried in abundance. A 90mm x 78mm (bore and stroke) engine gave excellent results, and this encouraged a try at even shorter stroke engines, which brought about some interesting problems. The Manx engine's built-up shaft did not lend itself to drastic stroke shortening, as the crankpin would begin to overlap the mainshafts. To get around this, some really off-beat layouts were tried, and a couple of examples are illustrated.

Getting the stroke down and crank speeds up presented Norton with a valvegear problem. That big pair of valves was reluctant to follow the cams at elevated speeds, and this resulted in a desmodromic head for the Manx engine. Desmodromic valve actuation, for those who do not know, is the type that has positive, mechanical opening and closing of the valves; no springs are used. Initially, the "desmo" Manx had the same valve timing as was used with the normal return-spring layout, but later the opening and closing rates were increased. When this was done, reflected inertia from the valves, through the valve gear, overloaded the towershaft couplings and broke them. The problem was overcome by substituting a splined coupling system, with external splines on the bevel gear shafts, and an internallysplined sleeve between them. This proved so effective that it was incorporated in the standard racing engines from 1959 onward. The desmo cylinder head, although promising, was abandoned.

Still another interesting cylinder head that was tried, and abandoned, was one with a rotary intake/exhaust valve. This followed the "Cross" pattern, with a barrelshaped rotating member across the top of the cylinder head. Passages cast into the rotary member let the mixture into, and exhaust products from, the cylinder. It is interesting, and instructive, to note that after a considerable amount of development work, power output from the rotaryvalve engine was brought up to equal that of the normal poppet-valve layout. Output never did exceed that available with poppet valves, and the rotary valve required copious lubrication, which caused an oiling problem in the cylinder. For that reason, the whole idea was dropped.

Somewhere at Norton, tucked away in a back room, is a bike that would have seen action had not the factory withdrawn from active participation. It had a very shortstroke version of the old single, with an external flywheel, and the engine was mounted horizontally. In this machine, the engine ran "backward," because the primary drive was through gears rather than a chain. The transmission was in-unit with the crankcase. Curiously, the famous "Featherbed" frame was replaced by a backbone-type frame with single large-diameter tube holding everything together.

In 1962, everything came to a halt in Norton's racing department. Production on the Manx has halted, and from that time on, only a few spares (and not really enough of those) were made. Even so, the Norton Manx, in both 350cc and 500cc form, remained the favorite of private entrants and these machines, now all getting well along in years, are still the mainstay of England's short-circuit races.

Tony Murphy, who owns one of the last Manx 500s built, gave us the reason for this in recounting his experiences. Even though a bit down on power as compared to things like the MV or Gilera fours, the Manx is available; the others are not. Also, if you give proper notice to the tachometer, and do not try to use too many revs, the Manx will be exceedingly reliable. Finally, and most important, the Manx is still the best-handling motorcycle in the world. The only criticism we have ever heard leveled at the Manx's handling is that it is too good. No matter how hard it is pushed, it will not do anything untidy to warn its rider that he is near the limit; the Manx does everything just right until the limit of tire adhesion is reached, at which point it deposits its rider on the hard, hard ground and slithers away on its side.

Where the Manx could be improved, according to Murphy (and we are inclined to agree) is in the engine department. Even though each engine has, at the time of leaving the "assembly line," pumped out 50 bhp on the factory's dyno, none of those in this country have shown that much on our dynamometers. A couple, very carefully set up, have given 46-48 bhp; never more. This contrasts strangely with the gussied-up pushrod-type singles running in our flattrack races, which get about 52 bhp. Hand the Manx engine over to these same tuners and after a season of experimenting they would probably have it cranking out 60 bhp, and running fairly reliably at 8000-8500 rpm. The outlook for a full season of trouble-free running would not be so good, but the power would be there.

At this writing, there is at least one such Manx "hot-rod" being developed, and as road racing (other than AMAsanctioned; the Manx is barred from their races) becomes more popular, there is promise of more to come. It may be that the Manx will reach the peak of its career now, long after the factory has given up. There is a shortage of spares, and this may force people to experiment with precisely the sort of non-standard replacements that could add substantially to the engine's power output. •

View Full Issue

View Full Issue