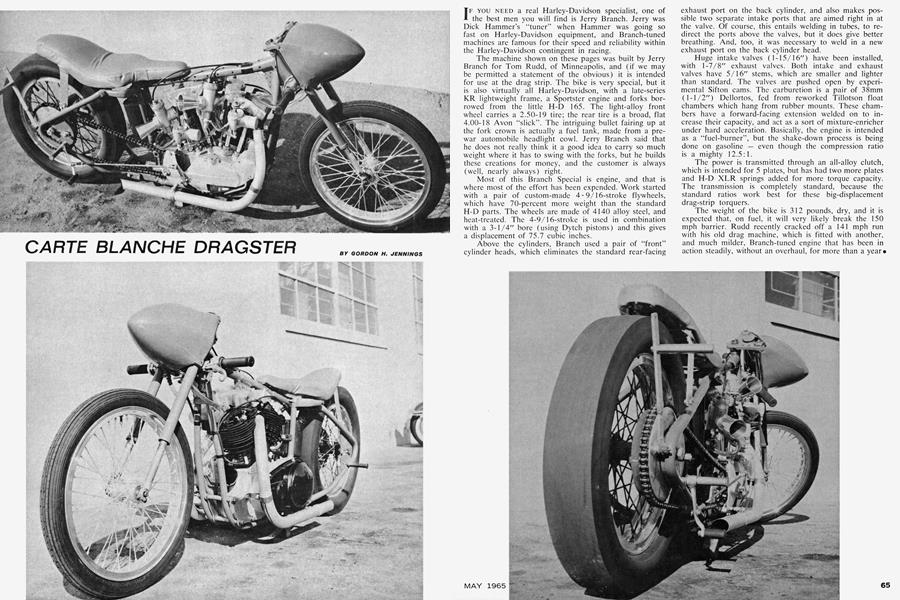

CARTE BLANCHE DRAGSTER

GORDON H. JENNINGS

IF YOU NEED a real Harley-Davidson specialist, one of the best men you will find is Jerry Branch. Jerry was Dick Hammer’s “tuner” when Hammer was going so fast on Harley-Davidson equipment, and Branch-tuned machines are famous for their speed and reliability within the Harley-Davidson contingent in racing.

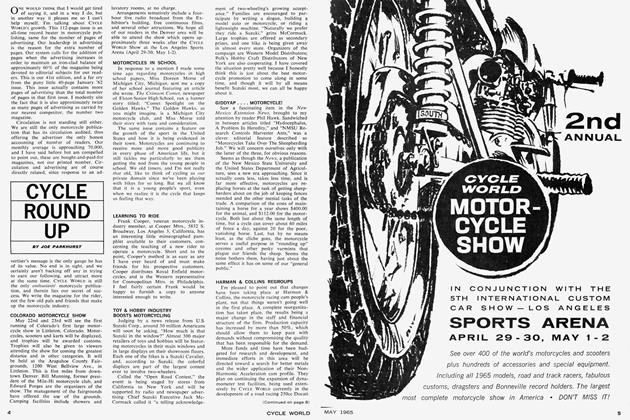

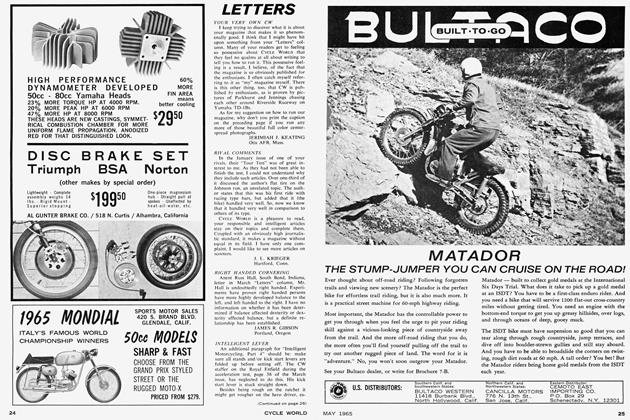

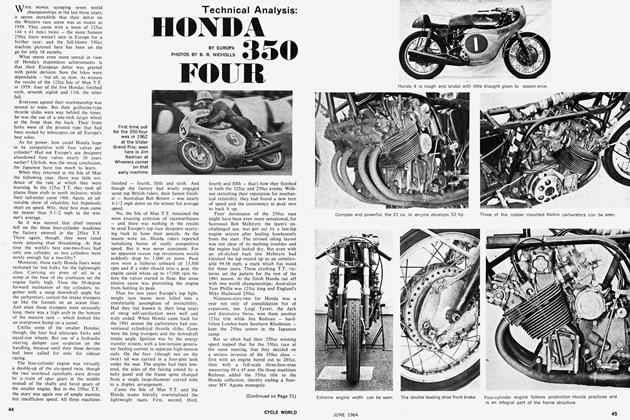

The machine shown on these pages was built by Jerry Branch for Tom Rudd, of Minneapolis, and (if we may be permitted a statement of the obvious) it is intended for use at the drag strip. The bike is very special, but it is also virtually all Harley-Davidson, with a late-series KR lightweight frame, a Sportster engine and forks borrowed from the little H-D 165. The light-alloy front wheel carries a 2.50-19 tire; the rear tire is a broad, flat 4.00-18 Avon “slick”. The intriguing bullet fairing up at the fork crown is actually a fuel tank, made from a prewar automobile headlight cowl. Jerry Branch said that he does not really think it a good idea to carry so much weight where it has to swing with the forks, but he builds these creations for money, and the customer is always (well, nearly always) right.

Most of this Branch Special is engine, and that is where most of the effort has been expended. Work started with a pair of custom-made 4 - 9/16-stroke flywheels, which have 70-percent more weight than the standard H-D parts. The wheels are made of 4140 alloy steel, and heat-treated. The 4-9/16-stroke is used in combination with a 3-1/4" bore (using Dytch pistons) and this gives a displacement of 75.7 cubic inches.

Above the cylinders, Branch used a pair of “front” cylinder heads, which eliminates the standard rear-facing exhaust port on the back cylinder, and also makes possible two separate intake ports that are aimed right in at the valve. Of course, this entails welding in tubes, to redirect the ports above the valves, but it does give better breathing. And, too, it was necessary to weld in a new exhaust port on the back cylinder head.

Huge intake Valves (1-15/16") have been installed, with 1-7/8" exhaust valves. Both intake and exhaust valves have 5/16" stems, which are smaller and lighter than standard. The valves are pushed open by experimental Sifton cams. The carburetion is a pair of 38mm (1-1/2") Dellortos, fed from reworked Tillotson float chambers which hang from rubber mounts. These chambers have a forward-facing extension welded on to increase their capacity, and act as a sort of mixture-enricher under hard acceleration. Basically, the engine is intended as a “fuel-burner”, but the shake-down process is being done on gasoline — even though the compression ratio is a mighty 12.5:1.

The power is transmitted through an all-alloy clutch, which is intended for 5 plates, but has had two more plates and H-D XLR springs added for more torque capacity. The transmission is completely standard, because the standard ratios work best for these big-displacement drag-strip torquers.

The weight of the bike is 312 pounds, dry, and it is expected that, on fuel, it will very likely break the 150 mph barrier. Rudd recently cracked off a 141 mph run with his old drag machine, which is fitted with another, and much milder, Branch-tuned engine that has been in action steadily, without an overhaul, for more than a year.o

View Full Issue

View Full Issue