[TECHNICALITIES]

GORDON H. JENNINGS

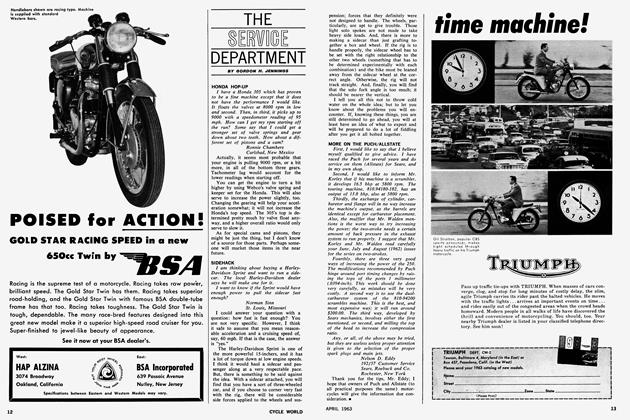

MISCELLANEOUS BITS of motorcycle hardware always seem to be floating across mv desk; this month I have a couple of dandies. From Tabloc, the people who make those fancy aluminum sprockets, there is a "dream wheel" to end all. For those who have never seen a dream wheel, and/or do not know what it is, I will explain. It is a sort of circular slide-rule, calibrated so that you can dial in rear-tire diameter and overall gear ratio, then read off in miles per hour relative to revolutions per minute. Tabloc's calculator does this, and in addition will also give you gear ratios — assuming that you know the number of teeth on the gears and sprockets involved. A very handy device for the racing fraternity, or for someone who is simply curious about what the engine in their touring bike is doing at some given road speed.

Another little goodie that particularly impressed me is a replacement shifting fork for the Ducati 250. This one is made by the Sturtevant Co., which is better known for a line of excellent torque wrenches. Although the Ducati is a remarkably good motorcycle in most respects, it does have its Achilles heel: the fork that ratchets the shifting-drum around. The fork is made from soft steel plate, stamped out by means of the well-known "cookie cutter" system, with a set of bent tangs in the fork jaws that engage the pins on the end of the shifting drum. It is a good arrangement, simple and inexpensive — but it gets bent out of shape if a rider tries to force shifts. Touring riders have little trouble, but the racers have come to hate this bit of steel-plate with a passion.

Sturtevant's replacement is machined from a better-quality steel, and instead of having the tangs bent out from open jaws, the tangs are machined and there is a bridge connecting them. It is most unlikely that they would ever bend. The jaws are, by the way, machined with a 2-degree undercut, and a letter from Lee Sturtevant tells us that the shift-drum pins should be given a matching 2-degree inverse taper. We plan to do this when we install one of the forks just described in our road racing Ducati.

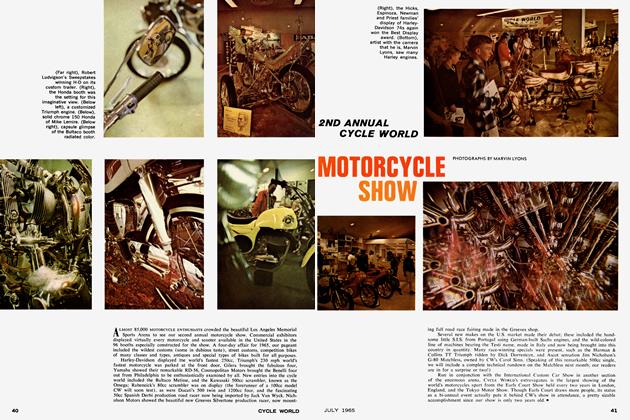

Speaking of road racing (as I usually am), a lot of people who attended the CYCLE WORLD motorcycle show and dropped by our booth there asked about my Honda-Cotton, which was not on display. The reason for its absence was that it has been sold. I have had a lot of fun with the machine, and some agony, and was sorry to see it go. However, racing it involved a real development project, and I cannot afford the time required for that sort of thing. So, rather reluctantly I decided to sell.

The Hotton is now the property of Mr. James Sitz, who will be racing the bike, and who will continue with development. There is an emotional attachment to the machine that will not let me simply forget it, so I will be a sort of consultant. We will be trying Precision Machining's 350kit pistons and oversize valve/racing valve spring kit. These items have been working very well in the PM-sponsored "SuperDuper Hawk" that Eric Dahlstrom rides (the bike is very fast and, after some initial bothers, quite reliable) and we think they are worthwhile.

(Continued on page 12)

Even though the Hotton is gone, I am not retiring from racing (or whatever it is I do when in a race). I will continue to campaign on our "Daytona" Yamaha TD-IB, which is very fast, requires relatively little maintenance, and will do the job without a lot 'of reworking. In fact, the only change that I have found necessary was converting to Girling rear suspension units. With the stock "legs", the TD-IB prances a bit on rough surfaces. Girling units purchased from our local Triumph distributor (serial #6405 4200ABR) cured the problem. These units are fitted, standard, with 132-pound springs, and I changed to 90-pound springs for the very light Yamaha. This combination gives exceptional handling with a bit of rearwheel hop when there are ripples in the paving. Nevertheless, where the course is smooth, the Girling-equipped TD-1B is so fantastically steady that I plan to retain the 90-pound springs except for our rougher courses, where 80-85 pound springs will be required — at a slight expense in handling precision.

Beyond this slight fiddling of the Yamaha's suspension, I have no immediate plans for modifications. At this point, the bike has more power than anything else in its class, and I cannot honestly claim to be using all that is available. As for sorting out reliability problems: I don't think there will be any. The bike has almost 500 racing miles behind it at this writing, and the engine seems to be just as healthy as when it was new. The cylinders have been off after every race meet — just to permit a check of the bearings — but that is more in the interest of inspection than anything else. Yamaha recommends frequent replacement of the caged-needle piston-pin bearings, and changing these every 250 racing miles is about all that is necessary.

Eventually, some modifications will be made, for there is more power to be had from the TD-IB and as it is there, I may as well have it. However, for the time there is the matter of learning to ride. At our last ACA road race, I elected to ignore tuning in favor of riding and managed a 3rd place, which is by far my best performance to date. It seems that in racing, one should not fiddle with things once at the track; it has a bad effect on the concentration that is essential to a good riding performance.

Now then, on to one of our favorite subjects: the AMA and what it should/ should not be doing. Although it may appear that we are "anti-AMA", the fact is that we fairly consistently support that organization. We give publicity to their events, and are participants in some of these as well as being AMA members. But, being members and supporters does not mean that we will not criticize when we think it necessary — and in our view it is often necessary.

At Daytona, for instance, we were made aware of several things of a "technical" nature that appear connected more closely to tradition than logic; and of things that experience in road racing indicate should be changed. In the latter grouping is the practice of some competitors in using two sets of handlebars. Being accustomed to high-and-wide handlebars, most of the competitors at Daytona use these on their road racing equipment — which is, I think, a mistake; but that is their business. This becomes actively dangerous when the highbars are supplemented by a set of clip-ons down at the fork legs. This enables the rider to tuck-in more cleanly on the straights while giving him a set of high bars for cornering. Unfortunately, there are no clutch or brake levers down on the clip-ons, and thus response to an emergency situation will be badly affected. A seized engine, when a rider cannot get to the clutch, will usually result in a mighty fall, and we know of at least one instance where this actually happened. The odds against transferring one's grip from one set of handlebars to the other (to get at the clutch and/or brake) are most unfavorable. I think perhaps the AMA's National Technical Committee should give this point some consideration at their next meeting.

(Continued on page 14)

Another situation that might be given some thought is the folding foot-peg rule. In scrambles, TT or flattrack, the folding pegs have logic in their favor, for it is easy to snag a peg in rough going, and there is the danger of having one's foot caught in front of a non-folding peg and of whacking a downed rider with same. Road racing is, however, a different matter. There is nothing to catch a peg, unless you leave the course — in which case the pegs, folding or otherwise, will be the least of your problems. And, the customary fairing will shield the pegs in any case. It appears to me that most of the danger connected with pegs in road racing is that the bolt holding the peg to the frame may work loose, after which the peg could easily rotate around and fold down. If the requirements for folding pegs is to be retained, the AMA should add a stipulation that the pegs be keyed in some way, so that even if the mounting bolt loosens, the peg cannot rotate. Better still, competitors should be allowed the option of rigid pegs.

Often, people will argue for folding pegs on the basis that if they ground, they do not upset the motorcycle. There is some merit in this, but it is hardly consistent with the rule that calls for a solid, 5-point fairing mounting. I very much prefer to mount a fairing rather loosely along the lower sides, for then if you get too far over in a turn and ground the fairing, the only penalty is a big graunch-mark. A more solid mounting will cause the fairing to lever the rear tire into the air and that can drop a bike very quickly indeed. In this connection, I think that the AMA technical inspectors should actually check each motorcycle, at each meet, to see that they can be banked over at 50-degrees from the vertical before grounding. This requirement is written into the rules, but to the best of my knowledge no check was made at Daytona, nor was any equipment on hand for doing so.

Finally, something should be done about the "approved for road racing" tires; most of which are not suitable at all. Apparently, the Technical Committee feels that anything with other than a knobby tread merits approval. In fact, of the tires listed as approved, only the Avon, Dunlop and Goodyear special road racing tires are equal to the job at hand. This is not to say that the rest of the tires listed are not good; they are simply not suitable. If everyone was using what are basically touring-type tires, there would only be the danger of peeling treads, which has not happened. However, as things stand, the differences in tires help to widen the gap in cornering speeds and that does create problems. Also, there is the possibility that an eager rider, using touring tires, will try to get around with an equally eager rider whose bike is fitted with the real thing — in which case Eager Rider A will very likely fall down and may take Eager Rider B with him.

I also note, in the "Regulations Covering Motorcycles Used in Formula "C" Road Racing Events," that "True fuel injection is not permitted." Fine. But what is "true" fuel injection? Does this mean direct, timed injection into the cylinders; or timed injection into the ports (as in the SU fuel injection system); or constantflow, high-pressure nozzles in the ports; or even the gravity-powered dribble provided by a Wal Phillips device?

Here, as in so many instances, the AMA's drafting of rules, quite apart from whatever intent lies behind the rules, is exceedingly bad. It is probable that a lot of the bickering between riders and officialdom could be eliminated just by rewriting the rules to make them more clear. We might even find that most of the rules make sense; there is no way of knowing as they are now written. •

![[technicalities]](https://cycleworld.blob.core.windows.net/cycleworld19650701thumbnails/Spreads/0x600/5.jpg)