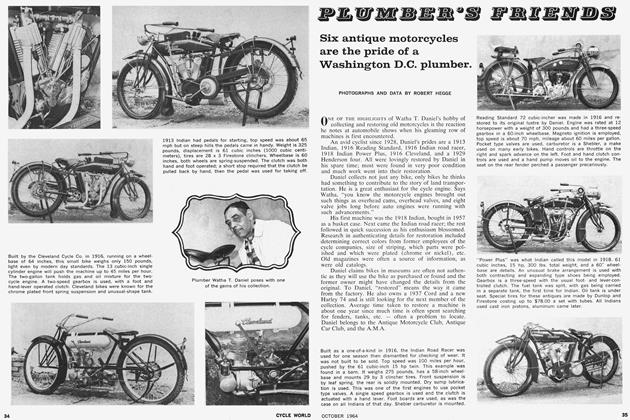

THE SERVICE DEPARTMENT

GARY BRAY

IT'S SHORT

At present I have a 1962 Ducati Diana and plan on doing some drag racing this summer. I am wondering about the best gear ratio for this type of racing. My machine has had some modifications; the stock 27mm carburetor has been replaced with a 29mm carburetor. Also the rear wheel sprocket has been changed from 45 teeth to 51 teeth. The countershaft sprocket is standard. This seems to work fairly well but first and second gear seem rather short. Could you suggest a better sprocket arrangement? Gerald B. Florey Minneapolis, Minn. The problem of first and second gear being short cannot be cured by a different sprocket combination; the difficulty lies in the transmission ratios themselves. To remedy this, a set of close ratio transmission gears should be fitted to your machine. Three gears and one shaft must be replaced to make this conversion. The cost of the gears and shaft, however, plus the fact that the shaft must be built up, hard chromed and reground, may make this change undesirable to you.

IRREGULAR RHYTHM

I have a 1957 Zundapp 250 which I use quite extensively. The engine runs well and gives a smooth ride, but while idling it has an irregular rhythm. A friend of mine says that this is typical of all twocycle engines, but / think it is due to re tarded timing. Is this true, and if so, please tell me how 1 can adjust it. I. A. De Wald Ridgewood, N. I. The two-stroke engine will also have this symptom if the low speed mixture screw is incorrectly adjusted. Since there are two possible causes let's take the igni tion timing first. The point gap should be checked at its widest opening and should have a gap of .012 to .015. With the spark plug removed, determine Top Dead Center on the compression stroke by in serting a small rod through the spark plug hole and marking it then using the outer edge of the plug hole as a reference point. Then measure up the rod 5/32 of an inch and mark it. Back the engine up until the points close, take a piece of thin paper such as cellophane from a cigarette wrapper, and insert it between the points. Rotate the engine forward until the paper will just slip out. Measure with the rod and correct by moving the generator (Continued on page 10) field housing. This can be accomplished by loosening the three screws holding it to the crankcase.

To advance the timing, rotate the assembly clockwise: to retard, counterclockwise. For a greater degree of accuracy and if the equipment is available, a dial indicator can be used. This will necessitate removal of the cylinder head. If a dial indicator is used, the correct measurement is' .157 B.T.D.C.

When this has been done, if the engine still does not idle as well as you feel it should, ride the machine some distance and allow it to become thoroughly warmed up. Then attempt to adjust the low speed mixture. This screw is found on the battery side of the carburetor, closest to the cylinder. Loosen the lock nut and turn clockwise until the engine becomes rough (or rougher, as the case may be). Then begin turning the screw out until the engine runs smoothly, and readjust the stop screw. Repeat until you are satisfied.

MORE GEAR TROUBLE

My bike is a 1959 Triumph TR-6B, owned and serviced by myself since new. The gearbox will not shift properly from 3rd to 4th. When running it out in 3rd it will not engage to 4th unless the motor is shut off and you hesitate before shifting. It doesn't grind going in or jump out; either it engages or it doesn't. I tore the transmission down to inspect the contents and found all the gears showing no visible wear. Only the camplate showed wear, so it was replaced and 1 thought my problem was solved. Then, while competing in the Mt. Misgah road race at Cripple Creek, Colorado, the same thing happened again. I hope you can give me a lead as to what my trouble is.

Lauren A. A nderson

Colorado Springs, Colo.

The first and easiest items to look at are the gear selection plungers, springs and shift return springs. These are located in the outer transmission cover, and may have become weak or damaged. If there is any doubt as to their condition, replace them. Next the camplate plunger and spring should receive the same scrutiny. This spring should be checked against a new one and replaced if there is much difference in length.

The mainshaft shifting fork can also cause trouble by being worn, bent, or if there is an excessive amount of play when the hardened steel roller that runs in the camplate is in its proper place on the shifting fork. Any more sideplay between the fork and roller than a few thousandths and the fork should be replaced.

The steel insert in which the camplate pivots may be moved in the transmission case. This can be checked by assembling all transmission components except the inner cover. The camplate and shifting forks should have clearance, but any more than 1/16 of an inch I would consider too much. If there is more than 1/16-inch clearance, the main transmission case should be warmed and the steel sleeve pushed in until the excessive space is taken up.

TURNING RED

/ have a 1963 BS A Star with 6000 miles on it. The bike won't run well on regular timing, only on advanced timing, yet my exhaust pipe is turning RED. Can you tell me what my problem is and how to solve it?

Jim Ewen Broadview, 111.

If this machine is equipped with an energy transfer ignition system I suspect the rotor may be out of time in relation to the stator windings. This can be caused by a broken key or worn keyway on the crankshaft. The end result is that you are timing the engine to the ignition rather than the other way around.

On the earlier BSAs fitted with this type of ignition system, the circuit breaker assembly has been found to move during normal operation. To remedy this, a small hole is drilled in the crankcase just below the circuit breaker assembly. This hole is then tapped and an Allen set screw installed. Once the machine has been timed properly and the set locked in place, the (Continued on page 12) circuit breaker can no longer move and change timing.

For any service on this type of ignition system I suggest you see your dealer.

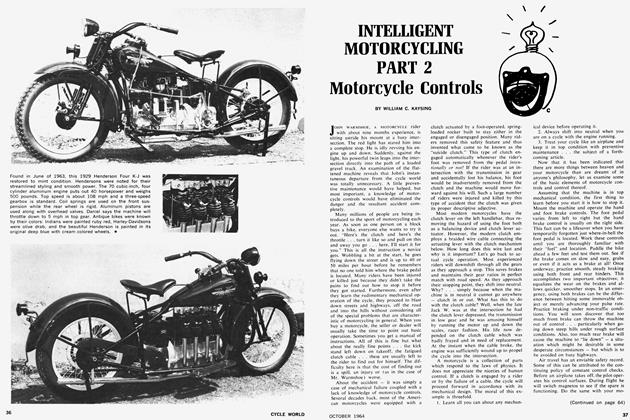

HARLEY 74 MAGNETO

1 would very much like some information on putting a mag in a 74 Harley. Please give me any information you have on wiring, etc., and also tell me if I have to change generators.

Amedeo Sant i Danbury, Conn.

Installation of a magneto on your 74 would be extremely difficult. On the only conversions I have seen, the generator was removed. The Harley-Davidson 55 and early flathead machines have the circuit breaker situated so that a vertex-type magneto can be installed without disturbing the generator.

NEW FRIENDS

I am planning to purchase a Honda 150. However, my friends are telling me that the 150 engine develops such a high rpm that the spark plugs burn out in no time at all. They also say that the pistons will give plenty of trouble because they travel too fast. I don't know if they are telling the truth or if 1 just need new friends. What do you say?

Dave Weaver Vallejo, Calif.

Spark plug burn in the Honda 150 is due to one or a combination of three things: the wrong spark plug (heat range), too lean a carburetor, or bad or weak condensers. Piston wear is affected by these conditions.

High rpm does not always mean heavy piston wear, however, as it is piston speed that determines piston life. An engine that runs at a higher rpm can have a lower piston speed than a slower turning engine, through basic design.

SIMPLE SOLUTION

The problem is this. Since overhauling the engine, my Yamaha YDS-2 "flattens," as if the fuel line was pinched off, at around 4,000 rpm then again at 6 and 7. 1 have increased the carb jets to .80, checked coil leads, ditto fuel tank. Timing, which 1 think is at fault, has ranged from 1.75 BTDC to 1.90. At present it is 1.75 (all set with dial indicator and voltmeter). The one thing that has helped has been plugs. I've tried every damn plug made, including a Champion N-3 that holed a pistan in five miles. Now 1 have NGK B8Ns. Cold it is very strong, pulling smoothly in the first four gears to 9,000 without too much hesitation. It will not pull higher than 5,000 in fifth, though, warm or cold. When it warms the slightest let-off of the throttle causes loud clanking noises that sound like detonation or pistons banging against the wall. Also, the miss becomes more pronounced.

1 run 16-1 Shell Premium in X-100 #30. Running to 20-1 makes no difference. When the engine falters there seems to be no diminution of the exhaust stream. Fuel block (on/off/reserxe) has been disassembled and cleaned. Needless to say 1 hope I'll hear from you but will understand if 1 don't.

Albert E. Güstin Garden Grove, Calif.

This is a very common problem with two-cycle engines when Shell X-100 has been used. This type of oil or, for that matter, any type of oil not designed expressly for two-cycles, just doesn't do the job. I realize the manufacturer recommended Shell, but whenever this oil has been used, particularly in machines that are run hard, it isn't many miles before a piston has seized or a mysterious hole has appeared.

WHAT TO USE?

/ recently bought a 1958 Cushman Mailster and am not happy with the performance of the 7.95 hp Husky engine and transmission. I was wondering if 1 could replace the present engine and transmission with some other engine and transmission, possibly a small foreign car type. Can you offer any suggestions?

Fred R. Patten Berkeley, Calif.

Boy, are you in for a lot of work. Probably the cheapest power unit to buy and install would be a war surplus HarleyDavidson 45 cubic inch side valve engine. Since the engine mounts of both engines are similar, fabrication of special mounts can be held to a minimum. As to type of transmission, the Harley three-speed would be ideal and you might even find one that has reverse in it.