THE SERVICE DEPARTMENT

GORDON H. JENNINGS

BRAKING TESTS

I am very much in accord with your discontinuation of high-speed runs on road test machines.

What I would like to see, in your road test data on machines tested, is a third graph, showing braking distances for each ten mph from top speed down to, say, twenty mph. Every cycle owner I have talked to in this area feels the same way. We would like to have stopping distances from various speeds, with both brakes, rear brakes only, and front brake only, included in each road test. Charles G. Schneider New Orleans, Louisiana

We have had many requests for specific data on braking performance, and we do think it is basically a good idea; but, there are practical problems that have, thus far, prevented us from obliging.

Essentially, the difficulty lies in getting consistent results. To be fair in presenting braking performance data, we would have to get the maximum from each machine tested, and that is more easily said than done. Maximum braking effort is obtained just before the brakes lock, and the tires begin to skid, and the only way one can be sure that this point is reached is to overstep the line slightly, and then ease back a bit until the skidding stops. Unfortunately, skidding the front wheel will almost certainly result in the test being completed with the motorcycle on its side, and the rider conducting a separate skid test all his own. Granted, it is not possible to lock the front wheel of most motorcycles on dry pavement, but there are exceptions, and the exceptions create the problem.

We have given some thought to using a braking meter, which gives stopping rates in terms of feet per second, combined with a spring-scale device that would enable us to apply a predetermined number of pounds of force at the control lever. This would give us a figure for stopping power versus pressure required, and that is all right as far as it goes. However, there are motorcycles with brakes that give a relatively large amount of retarding force with little pressure required at the control — and yield little more stopping power no matter how much muscle is applied. Conversely, some having a fairly heavy control-pressure requirement can be made to stop extremely quickly if enough muscle is available. Thus, the ratio of control-pressure to stopping rate is not an entirely fair measure of overall braking performance.

(Continued on Page 10)

For all of these reasons, “panic-stop” brake testing will have to wait until we can develop some method that is fair to all of the motorcycles we test. We will, of course, continue to offer subjective evaluations of braking performance. This might seem to be a contradictory policy, being affected by even more variables than those we have mentioned; but, we have an enormous collective experience with a wide variety of machines, and when we all agree that if in broad terms a bike has good brakes, or bad ones, then we can feel reasonably certain that is correct. Once we depart from this method, and begin to define “how good is good,” we get into an area of argument over decimal points and before that is done, we want to be very sure of our figures.

DUAL-PURPOSE YAMAHA

ƒ own a fast Yamaha YDS-2 and am contemplating converting it to the best compromise between a street and dirt machine. My problem is with gearing, mufflers and lubrication, as the suspension is easily changed.

Which sprocket would give me good power and still provide enough road speed to get me to events without running the engine at 8000 rpm?

The mufflers have to be changed completely; I’ve inquired with the different dealers but no one can suggest the type needed. I’ve noticed the Jawa• MotoCross has well-designed high-pipes that would probably fit, but would they provide enough muffling for street use and enough capacity for the 9000 rpm the engine will easily turn?

I’ve gummed or carboned up the engine twice in 3000 miles; now I’m burning a new graphited motor oil which gives excellent lubrication but burns very dirty. My mufflers are completely fouled and the bike smokes so much that people glare at me for being an obvious contributor to our smog problem.

1 have heard that the new chemical lubricants will provide very clean burning, but mixing the stuff to gasoline 12 to 1 at almost $2.00 a quart makes it prohibitive for the average rider. Peter W. Ries Hollywood, California

As you already appreciate, the same gearing will not do for both street riding and competition scrambling. And, any gearing you choose as a compromise will reduce the bike’s capabilities as a street machine without making it really well suited to dirt riding. I would suggest that you buy an extra countershaft sprocket, and a chain of the proper length, and install these items on the spot when you arrive at an event; reverting to the standard gearing for the trip home.

The YDS-2 has a countershaft sprocket that is obstructed only by an aluminum cover, and this can be trimmed away, as is done on the TD1 model, to give instant access. Ratio changes can, therefore, be made in a matter of minutes, using a very few tools that can easily be carried along on the motorcycle. The standard gearing is 5.94:1, overall, with a 16-tooth countershaft sprocket. Going down to a 14-tooth countershaft sprocket will change the overall ratio to 6.8:1, and at 50 mph (running on a “Universal” type tire, which you will need for what you plan) the engine will be turning just 6200 rpm — not comfortable, but something you can stand. Best of all, buy the 13-tooth countershaft sprocket and slip it on after arriving at the event in which you plan to run.

The mufflers are going to present a much more serious problem. Two-strokes are very sensitive to changes in exhaust systems, and the substitution of the upswept plumbing from a Jawa might not work at all well. What you really need is the Yamaha’s stock system — mounted about a foot higher. This would require custom made pipes to connect the exhaust ports to the mufflers, but it will also be the only completely satisfactory solution to the problem. Obviously, you will also have to fabricate some heatshieds to protect your legs from the hot pipes.

(Continued on Page 12)

I can offer a concrete suggestion for reducing the smoking and port and pipe fouling you mention: stop using so much oil in the fuel. The mixture specified by Yamaha is 20:1; not 12:1. For very hard running in hot weather, you might want to come down to 18:1, but the fuel/ oil ratio of 12:1 you are now using is excessively rich in lubricant and a certain cause of the fouling.

TRIUMPH TUNING

I would like to pass along a note which may prove useful to owners of the 1963 Triumph Bonneville (T120).

The carburetor adjustment procedures described on page 142 of the instruction manual, number 17, supplied with the machine, neglect the effects of the recently added pressure-equalizing tube connecting the two carburetors. Before attempting to adjust the idle per the manual’s instructions the rubber equalizer tube should be squeezed shut. To avoid damaging the tube, I suggest using vice-grip pliers with the jaws well protected with several layers of cloth. Each carburetor may then he adjusted according to the instruction manual; with the equalizer tube pinched shut no mixture will he drawn over from the unadjusted carburetor.

After both carburetors have been adjusted, open the equalizer tube and carefully backoff the two throttle-stop setscrews exactly the same amount. A steady and identical-sounding exhaust note should now be emitted from each exhaust pipe. Finally, with the engine stopped, very carefully take out the control cable slack so that both throttle slides just begin to lift together when the throttle is advanced.

You will then have the smoothest-idling and smoothest accelerating big-displacement machine manufactured today. Edward Getchell, Senior Eng., Adcom, Inc. Cambridge, Massachusetts Our thanks to Mr. Getchell for this interesting bit of advice.

Incidentally, we have heard of several instances where twin-carburetor Triumphs had carburetor mounting stubs twisted slightly from the proper horizontal position. When this condition exists, the float chambers, which are located to one side of the carburetor throats, will be raised or lowered, depending on the direction the stub is twisted, and the fuel level will be too high or too low. This can be the cause of persistent rough idling, and it should be corrected by loosening the stub’s set-nut and turning the stub until the carburetor is horizontal, with the slide chamber vertical as viewed from the bell-end of the instrument.

MORE BMW BPH

I am a college senior and have been riding for about a year. I ride my machine to and from school, and whenever 1 have spare time. Recently, 1 have gotten the bug for a little more powerful and faster machine. Unfortunately, I am unable to do this, being recently married, and with things rather tight in the money department.

(Continued on Page 14)

My machine is a 1951 BMW R25, 248cc. It is a wonderful machine, in excellent condition with only 6000 miles on it. Can 1 do anything within reason to make my BMW move out faster? By “within reason,” I mean by spending approximately $100. Any information would be greatly appreciated.

James L. Calderone

New Britain, Connecticut Frankly speaking, your $100 limit does not offer much latitude for engine modifications. However, there is some hope.

Assuming, as we must, that you are enough of a mechanic to do all of the work, you can get a small but useful increase by smoothing the ports, increasing the compression ratio, and fitting a slightly larger carburetor.

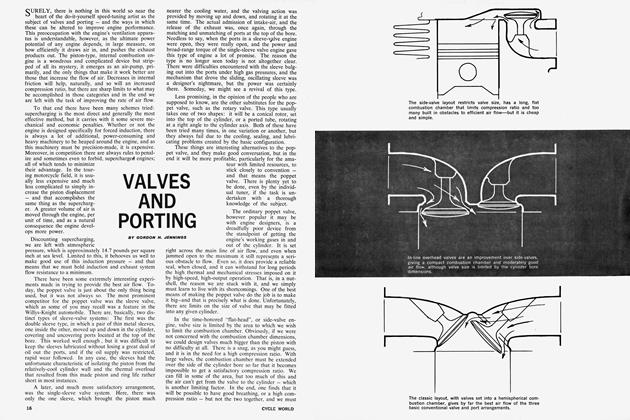

When working on the ports, do not attempt to enlarge them more than slightly; concentrate on removing any roughness and blending in any abrupt changes in the surfaces. You can also streamline the flow around the intake valve guide. Do not fiddle with the exhaust port beyond simply polishing away any roughness. Finally, do not try to get a glassy finish; a smooth ground or filed finish is smooth enough.

The compression ratio can be increased by taking the cylinder head to a machine shop (you will have removed it to do the work on the ports) and having them milloff 40 to 50 thousandths of an inch. I do not have any specific figures on the standard compression ratio of that early model, but removing the amount suggested should bring the compression up to about 9.5:1. That should provide a very useful increase in both power and torque. Of course, it will also increase the gas loading on the engine’s bearings and the thermal loading on the valves and piston; one must always be prepared to pay the piper. In connection with this increased compression ratio, it will also be necessary to retard the ignition a few degrees from the standard setting.

Selecting a larger carburetor is a bit of a problem, as T do not know if you want lots of torque or power at the top end. For the best torque, it would probably be best to retain the stock carburetor; maximum power would require a carburetor having a throat diameter of about 30 mm (1.18").

The price of a carburetor, and the necessary machine work, should come to just about the $100 maximum you have set for yourself. This kind of limit modification program also applies to any other small-displacement single, except those already highly tuned in their stock form. It will produce limited, but noticeable results, but one must not lose sight of the fact that reliability and smoothness will be adversely affected. There will also be a period of comparatively awful performance while ignition advance and carburetor jetting are being sorted out. •

View Full Issue

View Full Issue