FUEL-INJECTED HONDA

JOHN G. YOUNG

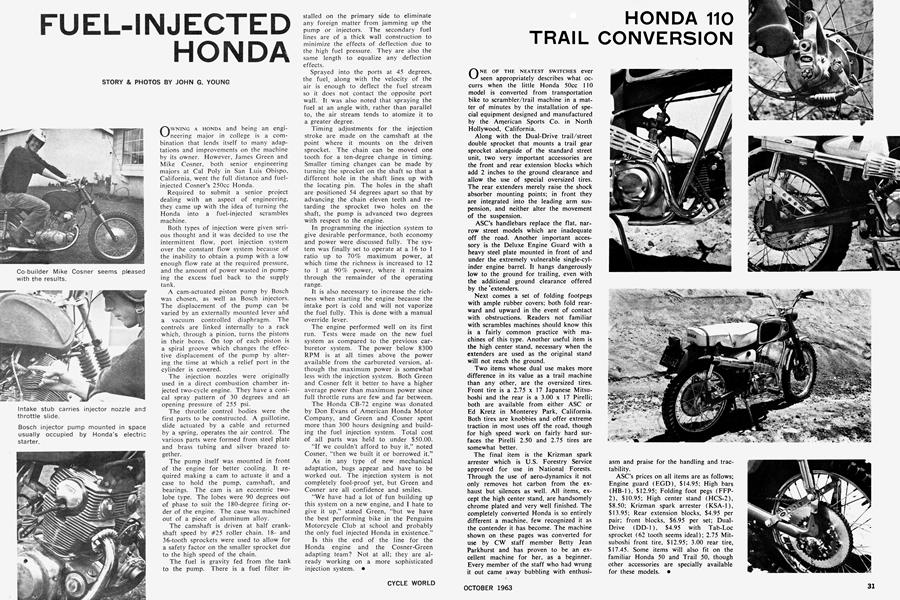

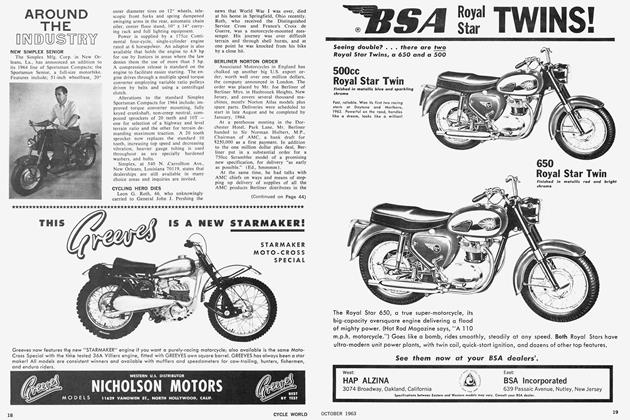

OWNING A HONDA and being an engineering major in college is a combination that lends itself to many adaptations and improvements on the machine by its owner. However, James Green and Mike Cosner, both senior engineering majors at Cal Poly in San Luis Obispo, California, went the full distance and fuelinjected Cosner’s 250cc Honda.

Required to submit a senior project dealing with an aspect of engineering, they came up with the idea of turning the Honda into a fuel-injected scrambles machine.

Both types of injection were given serious thought and it was decided to use the intermittent flow, port injection system over the constant flow system because of the inability to obtain a pump with a low enough flow rate at the required pressure, and the amount of power wasted in pumping the excess fuel back to the supply tank.

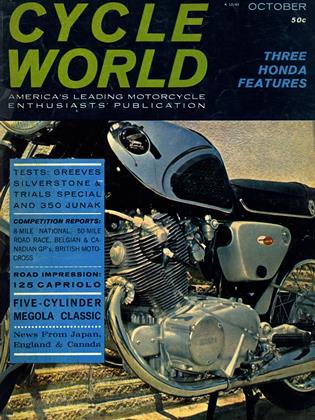

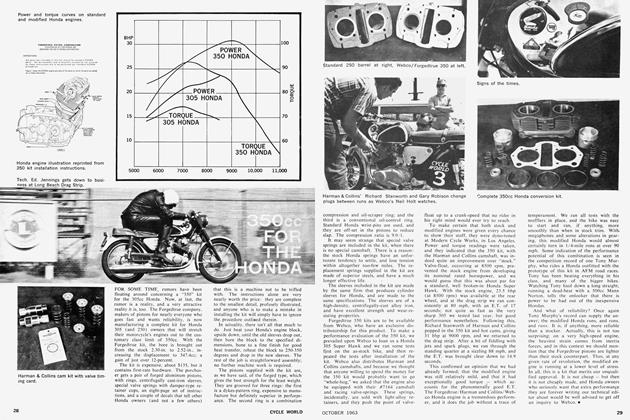

A cam-actuated piston pump by Bosch was chosen, as well as Bosch injectors. The displacement of the pump can be varied by an externally mounted lever and a vacuum controlled diaphragm. The controls are linked internally to a rack which, through a pinion, turns the pistons in their bores. On top of each piston is a spiral groove which changes the effective displacement of the pump by altering the time at which a relief port in the cylinder is covered.

The injection nozzles were originally used in a direct combustion chamber injected two-cycle engine. They have a conical spray pattern of 30 degrees and an opening pressure of 255 psi.

The throttle control bodies were the first parts to be constructed. A guillotine, slide actuated by a cable and returned by a spring, operates the air control. The various parts were formed from steel plate and brass tubing and silver brazed together.

The pump itself was mounted in front of the engine for better cooling. It required making a cam to actuate it and a case to hold the pump, camshaft, and bearings. The cam is an eccentric twolobe type. The lobes were 90 degrees out of phase to suit the 180-degree firing order of the engine. The case was machined out of a piece of aluminum alloy.

The camshaft is driven at half crankshaft speed by #25 roller chain. 18and 36-tooth sprockets were used to allow for a safety factor on the smaller sprocket due to the high speed of the chain.

The fuel is gravity fed from the tank to the pump. There is a fuel filter in-

stalled on the primary side to eliminate any foreign matter from jamming up the pump or injectors. The secondary fuel lines are of a thick wall construction to minimize the effects of deflection due to the high fuel pressure. They are also the same length to equalize any deflection effects.

Sprayed into the ports at 45 degrees, the fuel, along with the velocity of the air is enough to deflect the fuel stream so it does not contact the opposite port wall. It was also noted that spraying the fuel at an angle with, rather than parallel to, the air stream tends to atomize it to a greater degree.

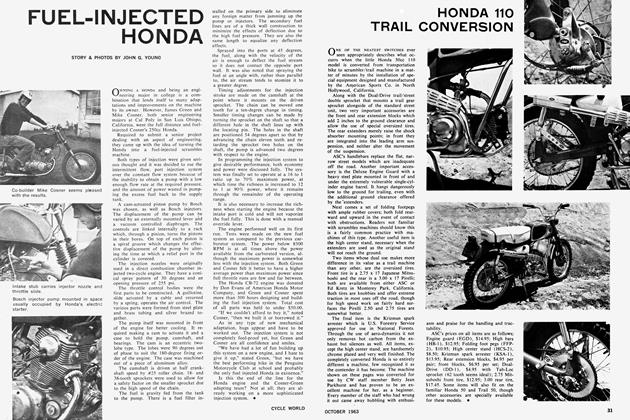

Timing adjustments for the injection stroke are made on the camshaft at the point where it mounts on the driven sprocket. The chain can be moved one tooth for a ten-degree change in timing. Smaller timing changes can be made by turning the sprocket on the shaft so that a different hole in the shaft lines up with the locating pin. The holes in the shaft are positioned 54 degrees apart so that by advancing the chain eleven teeth and retarding the sprocket two holes on the shaft, the pump is advanced two degrees with respect to the engine.

In programming the injection system to give desirable performance, both economy and power were discussed fully. The system was finally set to operate at a 16 to 1 ratio up to 70% maximum power, at which time the richness is increased to 12 to 1 at 90% power, where it remains through the remainder of the operating range.

It is also necessary to increase the richness when starting the engine because the intake port is cold and will not vaporize the fuel fully. This is done with a manual override lever.

The engine performed well on its first run. Tests were made on the new fuel system as compared to the previous carburetor system. The power below 8300 RPM is at all times above the power available from the carbureted version, although the maximum power is somewhat less with the injection system. Both Green and Cosner felt it better to have a higher average power than maximum power since full throttle runs are few and far between.

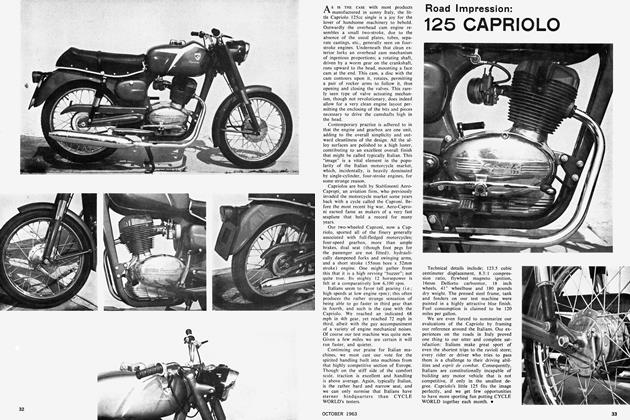

The Honda CB-72 engine was donated by Don Evans of American Honda Motor Company, and Green and Cosner spent more than 300 hours designing and building the fuel injection system. Total cost of all parts was held to under $50.00.

“If we couldn’t afford to buy it,” noted Cosner, “then we built it or borrowed it.”

As in any type of new mechanical adaptation, bugs appear and have to be worked out. The injection system is not completely fool-proof yet, but Green and Cosner are all confidence and smiles.

“We have had a lot of fun building up this system on a new engine, and I hate to give it up,” stated Green, “but we have the best performing bike in the Penguins Motorcycle Club at school and probably the only fuel injected Honda in existence.”

Is this the end of the line for the Honda engine and the Cosner-Green adapting team? Not at all; they are already working on a more sophisticated injection system.