THE SERVICE DEPARTMENT

GORDON H. JENNINGS

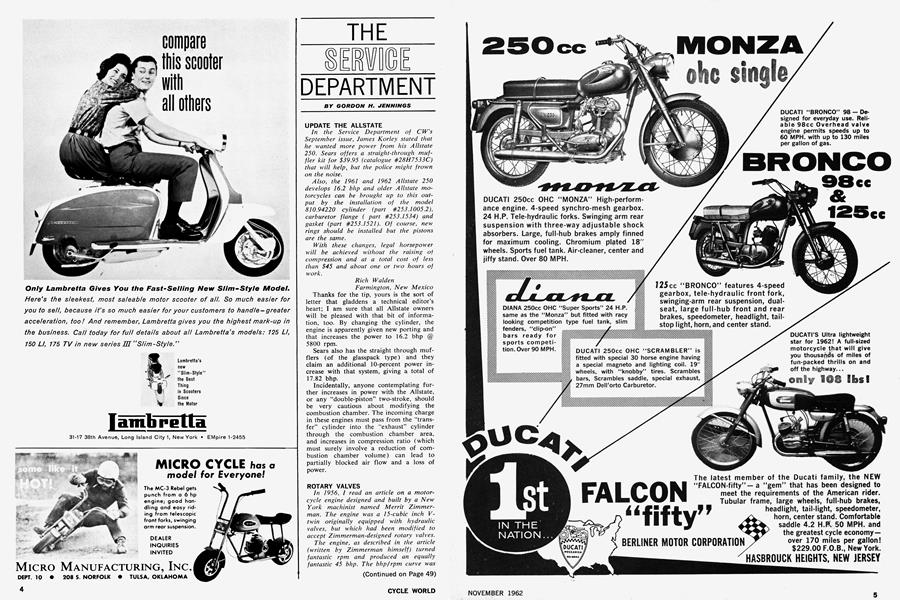

UPDATE THE ALLSTATE

In the Service Department of CW's September issue, James Korley stated that he wanted more power from his Allstate 250. Sears offers a straight-through muffler kit for $39.95 (catalogue #28H7533C) that will help, but the police might frown on the noise.

Also, the 1961 and 1962 Allstate 250 develops 16.2 blip and older Allstate motorcycles can be brought up to this output by the installation of the model 810.94220 cylinder (part #253.1005.2), carburetor flange ( part #253.1534) and gasket (part #253.1521). Of course, new rings should be installed but the pistons are the same.

With these changes, legal horsepower will be achieved without the raising ol compression and at a total cost of less than $45 and about one or two hours of work.

Rich Walden

Farmington, New Mexico

Thanks for the tip, yours is the sort of letter that gladdens a technical editor's heart; I am sure that all Allstate owners will be pleased with that bit of information, too. By changing the cylinder, the engine is apparently given new porting and that increases the power to 16.2 bhp @ 5800 rpm.

Sears also has the straight through mufflers (of the glasspack type) and they claim an additional 10-percent power increase with that system, giving a total of 17.82 bhp.

Incidentally, anyone contemplating further increases in power with the Allstate, or any "double-piston" two-stroke, should be very cautious about modifying the combustion chamber. The incoming charge in these engines must pass from the "transfer" cylinder into the "exhaust" cylinder through the combustion chamber area, and increases in compression ratio (which must surely involve a reduction of combustion chamber volume) can lead to partially blocked air flow and a loss of power.

ROTARY VALVES

In 1956, I read an article on a motorcycle engine designed and built by a New York machinist named Merrit Zimmerman. The engine was a 15-cubic inch Vtwin originally equipped with hydraulic valves, but which had been modified to accept Zimmerman-designed rotary valves.

The engine, as described in the article (written by Zimmerman himself) turned fantastic rpm and produced an equally fantastic 45 bhp. The bhp/rpm curve was practically a straight line. And, to prove that his engine was no laboratory miracle, Zimmerman grafted it to a Zundapp frame, sponsored a good rider on it, and set an admirable reliability and performance record in New York enduros.

(Continued on Page 49)

Zimmerman's article explained that the high output of the engine was due in part to good fortune, as the rotary valve setup on an engine originally designed for hydraulic valves did not allow full realization of the potential of rotary valves. He promised another article on an engine designed for rotary valves, but warned that the article might be some time in coming, for money and development time were scarce.

Six years have now passed, and nothing more lias appeared. Until last year, 1 had feared that Zimmerman might have turned his talents to more profitable pursuits, but then I spotted his name in a report on an eastern road race. So, Zimmerman is still around, and presumably the valves of his machine are still rotating. If anyone can locate Zimmerman, please send me his address. I would like to correspond with a man whose engine genius might make some of my motorcycle frame ideas go.

Darryl S krab a k

San Luis Obispo, Calif.

Like many people, Mr. Skrabak is afflicted with a grand passion for mechanical oddities, and although it will probably not do the slightest good, I will try to temper his enthusiasm with a few facts.

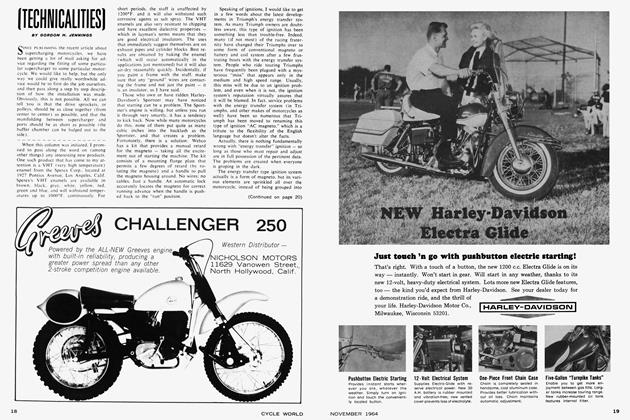

The rotary valve is nothing new; it has been around for almost as long as there have been internal combustion engines— and in no case has it ever demonstrated a superiority over the poppet valve. True, the rotary valve has the virtue of being entirely silent, and there is (due to the absence of reciprocating part») no limit to its operating speed, but it has a couple of inherent defects that no one has, as yet, remedied: poor sealing around the valve; and excessive oil consumption.

The most successful rotary valve engines, to date, are the Cross, and the Aspin. The Cross engine had a cylindrical rotary valve; an iron shaft running in the cylinder head with its lower surface exposed in the combustion chamber. The shaft had a through-hole that aligned first with an intake port, then blanked-off entirely for the compression and power strokes and finally aligned with an exhaust port — it was a sort of glorified two-way stopcock, driven at half-engine speed.

Actually, many rotary valve engines have been built to roughly this pattern, but the Cross engine is the only one that ever made much progress against contemporary poppet valve engines. Its success, such as it was, was due in large part to the unusual method of sealing the valve against the upper end of the cylinder. The cylinder was allowed to float slightly, and gas pressure forced the end of the cylinder against the valve — which was secured to the crankcase by means of a strap, shaped like an inverted U, looped over the valve body. Lubrication for the valve was provided for by oil fed under

pressure to the areas where it ran against the valve body. To prevent high rates of oil consumption, scrapers were included in the valve body to keep the oil from passing into the cylinder. This was, however, only partially successful; oil consumption remained a problem with the Cross engine throughout its life.

The Aspin rotary valve is an entirely different type — but with virtually identical problems. In the Aspin layout, the valve is conical, and seats into a conical recess in the cylinder head, rotating on the cylinder axis. Part of the valve cone is cut away, and this covers and uncovers ports in the cylinder head, and also masks the spark plug during most of the actual combustion process. Again, gas pressure is used to seal the valve, but in this instance the pressure is used to force the valve cone against the ports; the cylinder and its head are attached in the normal manner.

As may well be imagined, the expansion and contraction of the valve components in rotary valve engines does create some terrific sealing problems. The Aspin design comes off a bit better in this respect; when it expands, the valve cone simply moves down in its seat. The Cross design, on the other hand, meets the problem only by allowing the entire cylinder to float. Both designs suffer considerably from the fact that the metal in the valves is not disposed symmetrically; there are thick areas and cut away portions in both types of valve and this causes a substantial change of shape (just as is the case with 2-stroke cylinder barrels) with changes in temperatures. In neither case is the sealing ever as good as that obtainable with the poppet valve.

As I have said, the rotary valve has the virtue of being entirely silent. It also has a liking for high compression ratios, or, alternatively, for low-grade fuels. The valve makes the combustion chamber a bit peculiar in shape, it does away with the hot exhaust valve and, therefore, with a major source of combustion difficulties. In practice, compression ratios as much as two or three numbers higher than that with a comparable poppet valve layout have been obtained, and compression ratio has a very great effect on power output.

This brings us to one of the more interesting aspects of the poppet versus rotary valve controversy: there is little to choose between the two insofar as volumetric efficiency is concerned. The rotary valve will not feed air into the engine any better than the old, conventional poppet valve. It will, of course, operate at a higher speed than the poppet valve that is being operated by a pushrod and rocker system, but for a mechanism of equal complexity — which includes any overhead camshaft mechanism up to and including the desmodromic type of valve actuation — the poppet valve is at least the equal of the best rotary valve systems. If crankshaft operating speeds could be drastically increased over what is now the practical maximum, the rotary valve might come into its own, but for the time, the poppet valve is still the best. •

View Full Issue

View Full Issue

More From This Issue

-

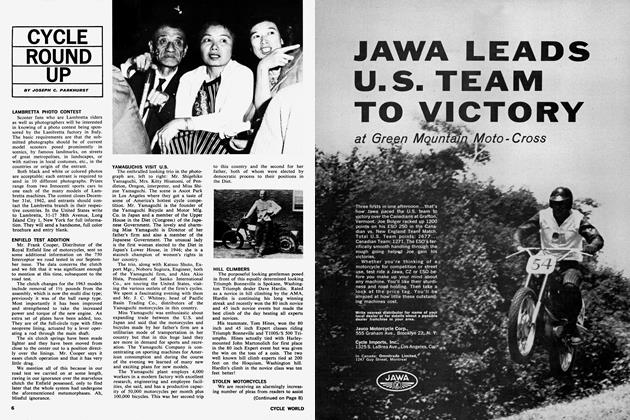

Cycle Round Up

November 1962 By Joseph C. Parkhurst -

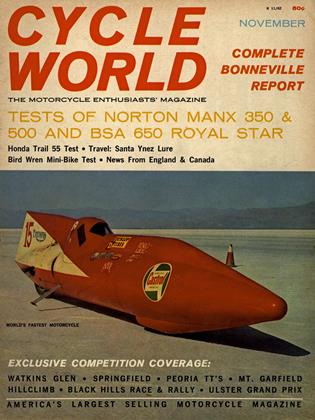

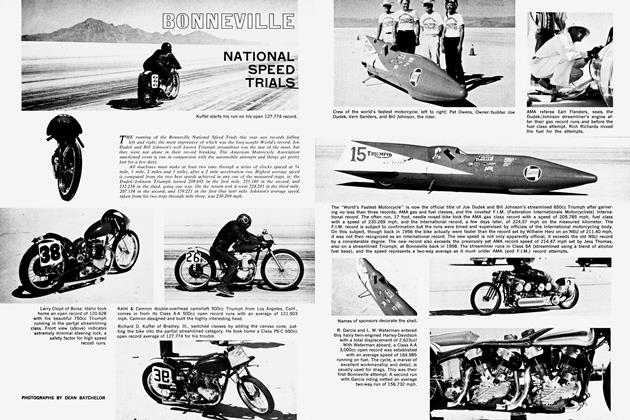

Bonneville

November 1962 -

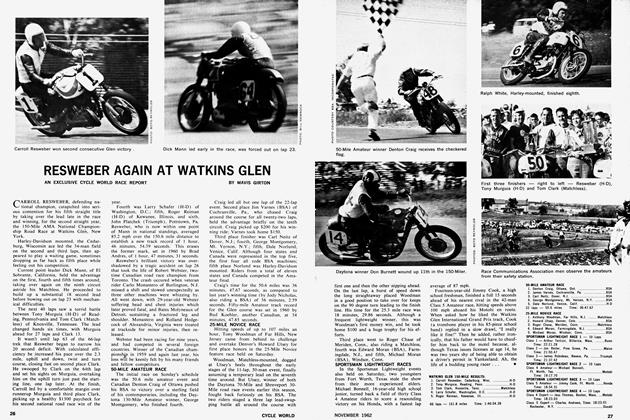

Resweber Again At Watkins Glen

November 1962 By Mavis Girton -

An Exclusive Cycle World Race Report

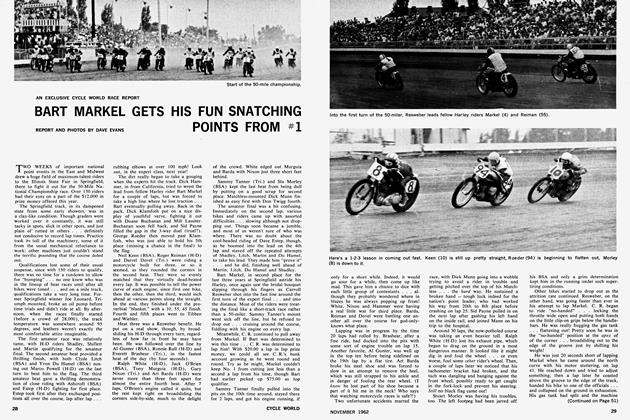

An Exclusive Cycle World Race ReportBart Markel Gets His Fun Snatching Points From #1

November 1962 By Dave Evans -

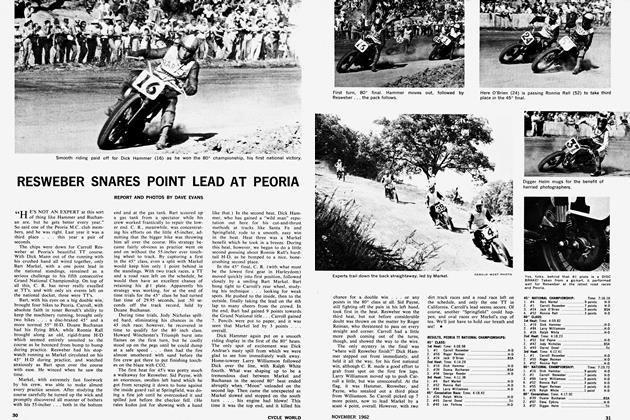

Resweber Snares Point Lead At Peoria

November 1962 By Dave Evans -

An Exclusive Cycle World Race Report

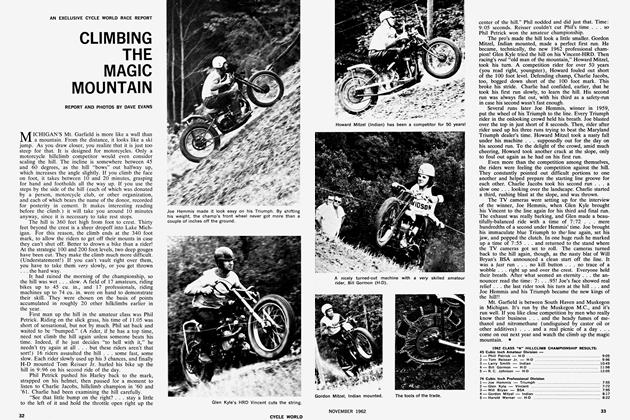

An Exclusive Cycle World Race ReportClimbing the Magic Mountain

November 1962 By Dave Evans