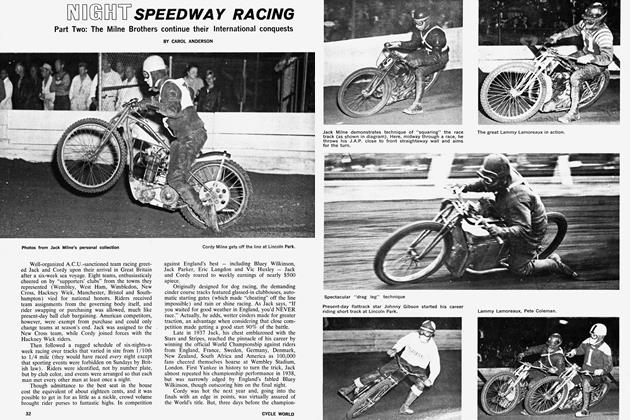

THE SERVICE DEPARTMENT

GORDON H. JENNINGS

VALVES AND RINGS

I would like to ask two questions: If, upon having doubt as to the condition of a set of rings that have been recently installed, and after removing the barrel and finding rings and cylinder in good condition, is it all right to replace the barrel with the same set of rings? Will the rings reseat, or do the rings constantly move around so that it doesn't make any difference?

What is the safe limit as to the amount of valve seat area that can be left on the seats when working over the valves and seats? A sixteenth of an inch or so? David White Hawthorne, Calif.

Taking first things first, I would say that there is every reason to expect that a set of rings in good condition can be reinstalled as often as circumstances re quire. As you apparently suspect, the rings do move around a good bit, unless they are pinned, as in most two-strokes, and do not "bed-in" in the usual sense of the term. Ring break-in really consists of a mutual honing process between the rings and the cylinder wall and the removal and replacement of the rings will have no effect on that.

The ring rotation is an interesting phe nomenon. It is caused by small mis-align ments between the axis of the crankshaft's main journals and the crankpin. Some errors in the alignment of these axis are all but unavoidable at normal manufactur ing tolerances. When they are present, they impart a back-and-forth twisting mo tion to the piston as it travels up and down the bore. The ring, bouncing up and down slightly in its groove, provides a "ratcheting" action that sets it twirling.

It may all sound rather insignificant, but a variation in alignment between the mainshafts and the crankpin of just a half of one degree will give a total back and forth piston movement of a whole degree. That movement can represent one entire revolution of the ring in just 360 turns of the crankshaft. Or, with the engine turning at the rate of 3600 rpm, the ring would be revolving at 10 rpm. It all sounds far-fetched, to be sure, but as anyone who has made a study of the subject can tell you, the effect is present to some extent in all engines.

J~LI~~ LII 1411 I1~III%~~. •As for the question about valve seat width, I would say that the answer would depend to some degree on what use you have in mind for the engine. For racing, it is not unusual for engine builders to shave the seats down to 1/32, and sometimes less. Touring engines, on the other hand, will be a bit less apt to burn their valves if the seats are made slightly wider — 1/16 or 3/32, depending on the specific engine.

(Continued on Page 40)

The reasons for the selection of seating width are complicated. In touring engines, the “slow” valve timings leave the valves against the seats for a relatively long time, and there is ample opportunity for the valve head to transfer a substantial part of its heat load to the valve seat, where it will travel into the head and to the cooling fins. And too, a relatively wide seat is not so likely to develop leaks over long periods of unattended service.

In racing engines, the extreme valve opening duration makes heat loss to the valve seat difficult, and the wide seat is of no benefit in that respect. On the other hand, there is an improvement in flow past the valve seat area as the seat is narrowed and that is why the builder of racing engines resorts to such techniques. Of course, the effective life of an extremely narrow seat is not very long, but in competition that is of minor consequence.

One point I would like to make is that if the seat is made too narrow, the hammering of the valve head against the seat will promptly widen it until there is enough area to support the load. Therefore, there is not much to be gained by getting carried away when trimming the valve seating area.

TOP SPEED

ƒ have just finished reading your February issue of CYCLE WORLD, and it was very interesting. But, I found one mistake on your Harley-Davidson 250 Sprint road test. In your magazine it said that the top speed of the Sprint is 73 miles per hour. 1 told a friend who owns a Sprint about this and he blew his top and told me not to believe everything 1 read. He said he would show me how fast it would go.

We went out to a road where the speed limit was 65 mph and he got going as fast as he could in the space of about one mile. We were doing 82 mph and still climbing when we were forced to slow down. My friend says he could go much faster alone.

1 think I know the trouble with your test machine, it is the carburetor stop used for the break-in period. These come on all new Sprints and possibly you didn’t know about it.

Tom Buyea

Coral Gables, Fla.

We get letters like yours rather often. As a matter of fact, when you cite instances of high speedometer readings, you leave us entirely unimpressed. You might note that we include on our data page a tabulation of speedometer error, and you might further note that in most instances it is considerable.

Our test procedure is somewhat involved and I will not go into it too deeply here, but I would like to say that we do not use the speedometer when making our high-speed runs. Experience has shown us that the error, which is often bad enough at 50 or 60 mph, gets completely out of hand as the bike approaches its top speed. Therefore, we actually time the machine being tested over a measured distance, making at least two runs, and we give both the best speed obtained, and the two-way average.

At the risk of sounding obvious, I would like to say that, while it is quite correct to say that one cannot always believe what one reads, your friend might have extended that bit of wisdom to include speedometers as well as publications.

BLACK IS THE COLOR ....

In reference to “Go Black for Go” 1 believe Mr. Butler appreciates the need for radiant cooling, but doesn’t understand engine power and efficiency relations.

The heat energy from fuel is split three ways, approximately 1/3 to power, 1/3 out the exhaust, and 1/3 to heat loss through the metal walls and into the oiL Other things being equal, more heat transfer through the walls will decrease power. Of course, in a highly tuned engine, better cooling is often required to prevent burning or seizure.

As to the .5 bhp increase mentioned, 1 would say that if about 50 bhp (approximate average for a well-tuned 500cc engine) was involved, .5 bhp is only 1 percent, and easily within the expected errors for measurement for even an expensive dynamometer.

J. Bob James

Canoga Park, Calif.

You are, to some extent, quite right about the business of heat and engine power, but Mr. Butler’s comments still hold good. It is all very well to discuss theoretical efficiency — which I will very likely do in some future article — but when you get down to hard cases, an engine that is not efficiently cooled will not be able to produce much power.

Internal friction is an impossible problem at elevated temperatures; it is not practical to provide enough clearance at “cold” to compensate for the expansion of the piston. More important, it is not possible to avoid piston failures unless cylinder temperatures are held within reasonable limits.

Finally, I happen to have some knowledge of the .5 bhp-gain example mentioned by Mr. Butler, and I can tell you that it is really true. The experiment was, I believe, made by BMW on one of their 250cc singles, which had a great deal less than 50 bhp. And, small capacity dynamometers can be made to give readings accurate to much less than a 1% error, even when the total power involved is down in the 10-or-less bhp range. Granted, the average dynamometer probably operates a trifle more loosely, but fantastic accuracy is possible and it is achieved whenever it becomes necessary, as it was in this instance. •

View Full Issue

View Full Issue