DEMOCRACY OF TECHNOLOGY

How HRC races to the future to win championships and improve our motorcycles

January 1 2020 Kevin CameronHow HRC races to the future to win championships and improve our motorcycles

January 1 2020 Kevin CameronDEMOCRACY OF TECHNOLOGY

KEVIN CAMERON

How HRC races to the future to win championships and improve our motorcycles

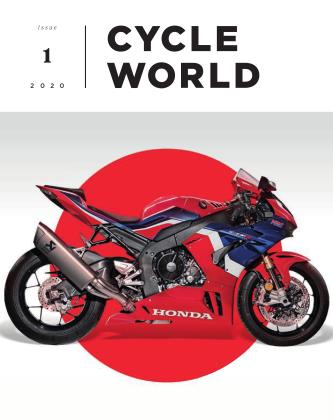

When a stunning new model appears, wouldn’t you like to know how it came to be? Honda’s new 2020 Fireblade CBR1000RR-R is my current example. Why did Honda launch this 214 hp bike, with MotoGP’s racy 81.0 x 48.5mm bore and stroke, in a time when sales of big sportbikes have shrunk so much?

Thinking about this, Honda Racing Corporation, HRC, seemed to be a key. Its red, blue, and black logo has emblazoned a great many high-technology championshipwinning bikes, onand off-road, whose technology has then been shared with the rest of us in production machines. What is HRC’s role in the new Fireblade? How does its work influence production motorcycles?

Fireblade is clearly aimed at winning in World Superbike, where Honda has needed stronger performance for some time. Where does the “Super” come from? Does HRC, Honda’s racing organization formed in 1982, get involved at the start? Or does it add what it knows after the new product-design team has outlined the basics?

These questions have been with me for years, so when a door at American Honda swung open and a beckoning finger appeared, I was ready. A video conference with HRC directors? Yes! Then to Japan and into HRC’s hallowed shop itself, including a meeting with Fireblade’s large product leader (LPL), Yuzuru Ishikawa? Book the tickets.

A VIDEO CONFERENCE WITH HRC DIRECTORS

In California, first came a visit to Honda’s informal museum in Torrance, including a reproduction of the company’s original tiny US storefront on Pico Boulevard and a look at a selection of historic and victorious HRC-built roadrace, dirt-track, and motocross bikes. Then a run to the super-sano HRC-run Supercross shop, which builds its riders a brand-new bike for every event, and is more about controlled process than hardwaremaking it right with many beautiful parts. And then to a large conference room and the video meeting using Honda’s private line to Japan.

Like other Japanese engineering companies, Honda practices engineer rotation to bring together contrasting talents. HRC director Tetsuhiro Kuwata introduced himself: “I was working for Formula One until 2008. I was moved to the motorcycle held in race management, not development. Rider negotiation, organizing teams, etc.”

Director Shinya Wakabayashi leads the development division. “I supervise all different types of bikes in HRC. I was with HRC from 1990 to 2005. Then in Superbike for two years. Then on to designing the RC211V—I was responsible for that (Honda’s first MotoGP bike, taking two championships 2002 and 2003). Then to mass production, and in April 2018, I came back to HRC.”

We asked why HRC was created, and Kuwata explained that racing was at first self-defense for Honda.

“At first the Honda business was only inside Japan, so they tried to get No. 1 technology in Japan,” Kuwata explained. “World racing was very high technology [of European builders in 1959], so they worried about those companies coming to Japan and destroying Japanese industry. Racing helped us understand our position in the world. If we win No. 1 in the world, it means we would also be No. 1 in Japan. It’s a simple approach but a big challenge.”

Mr. Honda himself had attended the Isle of Man TT races in 1954 and saw that European machines developed more than twice the power of Honda’s best.

By intensive development, Honda’s classic four-stroke grand prix bikes of the 1960s became championship winners. By 1961 Honda had become the world’s highest-volume motorcycle manufacturer, and had won its first GP race. Having made its name worldwide 16 world championships later, after 1967, Honda withdrew from motorcycle GP racing to launch its auto business.

He made a loose-wristed gesture with one hand as he replied, “It was flopping. ” “Bending from side to side?” I persisted. “Yes, bending.” Operation at high revs imposes special requirements.

After Honda’s 1970 US Daytona 200 win with Dick Mann on the four-cylinder CB750, Honda racing seemed to hibernate. In 1973, Kuwata said, to support European efforts in endurance racing: “Honda created the Racing Service Center (RSC). After that you know Honda created NR500 [the oval-piston V-4, developed by a group called NR Block], This was developed in the R&D center, but RSC was in charge of racing. These were separate organizations. For efficiency in all racing categories, all efforts were combined in 1982 as HRC.”

HRC’s first president was Shoichiro Irimajiri, who had designed Honda GP bikes such as the 18,000 rpm 250cc six-cylinder on which Mike Hailwood took two world titles.

“HRC is a completely separate company,” Kuwata continued. “If it is not separate, then it is easy [for corporate administrators] to stop. So isolating it separately protects it.”

Racing is very expensive, and it can sometimes be difficult to argue in favor of direct benefits to the bottom line of the company, but Kuwata goes on to explain the benefits of racing for the company as a whole.

“Racing activity is very quick,” he said. “We need a quick reaction. Production bikes can spend two to three years in development, but the maximum in racing is six months. If we need to react with countermeasures, changes must be made in one or two weeks. This is not just for technical things; it is also about our working approach. How to handle a big program. All engineers come in to learn many things.”

We asked Wakabayashi about the valuable mass of information generated in both racing and production. How is it stored? How is it used?

“If there are issues difficult to solve, R&D discusses it with HRC,” Wakabayashi explained. “We always work together when we must overcome issues in the production department. For some problems, we are able to directly research through our data.”

Kuwata added: “It is difficult to write all the things in a report. Many things happen—it is engineering experience—sometimes it is only in the people. Not only on paper, not only in a database.

“Older people try to teach the younger to push, push, push. When we are young, we think it is too much, but after five or 10 years, we understand, so we push, push, push.”

This made it clear that much valuable information resides only in the engineers and technicians—they are “human capital.” While in many companies accountants are those promoted to management, at Honda, experienced engineers can aspire to leadership.

We asked Kuwata why Honda’s MotoGP bike has V-4 power yet the new Fireblade is an inline?

“This question is the most difficult!” Kuwata said, with a laugh. “Because the market is smaller [for big sportbikes], it is very difficult to make two types of bikes in one category. We had V-4 [VFR superbikes] in the past, but for myself, I would like to have both. Many reasons for not having both—it’s not a technical decision but a business one. Best to ask the sales department!”

We asked about the many unusual engineering experiments made by HRC, citing oval pistons as one shining example of this.

Wakabayashi’s response was plain and beautiful:

“The basis of HRC’s work is that we challenge things that have been said to be impossible. If you think something is impossible, it is impossible. Our job is to find the possible.”

TO JAPAN AND HRC

In Japan and looking up at the HRC building, I wondered if the antennas I could barely see were the fabled data links used in FI racing. Inside, we were led to the assembly shop that has served MotoGP since its beginning. One of the 213s on the lifts clearly had a carbon swingarm, but our focus was a Fireblade test article with a familiar duct-taped message across its tank: “Air, oil OK. No gas.” How could we be in this inner sanctum? Surely only because the team was away at the Sepang, Malaysia, preseason test. We savored the atmosphere and moved on.

Next came an amazingly candid discussion with 2020 Fireblade large project leader Yuzuru Ishikawa. As he pointed out the features of a cutaway display engine, prominent in the background was a banner proclaiming “Born to Race.”

To my question, “Why adopt the 81.0 x 48.5mm bore and stroke of your RC213V MotoGP engine for this production bike?’ he replied: “By using the existing MotoGP combustion chamber, piston shape, and entire intake port, we saved time that would otherwise have been used in step-by-step development of those components.”

This “combustion module,” proven through 18 seasons of development in MotoGP, goes back even further—to that of the V-4 RC-45 Superbike, whose highly developed top end was adopted as the model for Honda’s first

MotoGP engine, the 990cc V-5 RC211V (whose engine design project leader was HRC director Wakabayashi).

DIFFERENCES BETWEEN V-4 AND INLINE ENGINES

I asked Ishikawa how it came to be that Honda’s MotoGP engine is a V-4 but its Superbike is an inline.

“An inline engine is very compact, short. It packages very well with all the equipment that a production bike must carry. In comparison, a V-4 is very long.” (Its wide, 90-degree V angle creates this length. —Ed.)

And now the question I’d saved until then: “Today in MotoGP, people are saying that something is holding back inline engines, making them less powerful than V-4’s. Why do you race a V-4 in MotoGP yet now you are preparing an inline to race in World Superbike?”

The highest MotoGP top speeds are recorded by the V-4’s of Honda and Ducati; with the inlines of Yamaha and Suzuki often slower by 6 to 10 kph.

“I am an inline guy,” Ishikawa began. “I like inline engines. The inline crankshaft is stable to 16,000 rpm, so this is good for World Superbike”—where mandated four-cylinder redlines range from 14,700 to 16,100 rpm], “But for the 18,000 we need in MotoGP, the inline crank becomes too ‘active’ and creates many problems.”

Click. It all became clear. As cylinders hre, a crankshaft is spun by torque pulses. When those pulses come frequently enough to be in step with the crank’s frequency of torsional (twisting) vibration, that vibration’s amplitude rises steeply, in turn winding up the camshafts, rattling the gears or chain that drives them, resulting in rapid fluctuations in cam-lobe velocity. In a Honda SAE paper I had just read, such variations were found to cause valves in FI engines to “float” (be flung off their cam-lobe profiles) as much as 1,500 rpm lower than the math said they should. Stronger valve springs solve nothing; their high pressure just scores cam and follower surfaces. Crank vibration, by upsetting the valve train, forces engineers to accept more-conservative cam profiles, while gobbling time and resources needed elsewhere. Less power is a natural result. For the shorter, stiffer crank of a V-4, little of this applies.

This has history. Engines of early racing cars (c. 1910) had four cylinders, never six. Why? Because the springy extra length of a six-cylinder crank allowed it to become torsionally excited at lower revs than a four, rattling its cam drive, winding up its cam, and floating its valves prematurely. The result was uncompetitive power.

Studying the cutaway Fireblade engine, I saw nothing tricky about its valvetrain, save for its FI-derived finger followers, which are much lighter than the inverted bucket tappets that have served so many motorcycle engines over the years. But what is this hybrid cam drive: by gear from the right-hand crank end to a combined gear-and-sprocket just above it, which in turn drives a silent chain turning both camshafts? As usual, the chain’s free runs are protected from “bowstring” vibration by rubber-faced tensioner blades pressed against them. So why this gear drive at the bottom?

This was wonderful—to be given this clear view of the ups and downs of development.

“This chain drive was at first for us a bottleneck for the whole design. No matter what we did, we had cracking of chain plates and damage to the tensioners.”

“Did black rubber from the tensioner blades show up in the engine oil?” I asked.

“Yes, we had that too.”

Also clearly visible in the cutaway Fireblade engine was the flaring webbed shank of one titanium connecting rod. For those of us accustomed to years of straightshanked steel sportbike con rods, this was a surprise, so I asked Ishikawa about it. He made a loose-wristed gesture with one hand as he replied, “It was flopping.”

“Bending from side to side?” I persisted.

“Yes, bending.”

Operation at high revs imposes special requirements.

This was wonderful—to be given this clear view of the ups and downs of development.

In most production engines, the 2-to-l reduction between crank and cams is achieved by giving the crankshaft sprocket half as many teeth as the cam sprockets. If the cam sprockets have, say, 34 teeth, the crank sprocket must have 17 teeth. Think of a wheel with 17 flat sides, rolling on a smooth road: It rises and falls. That’s just what the cam chain does as it wraps around a sprocket —and the fewer teeth that sprocket has, the “bumpier” the ride and the greater the vibration it feeds into the chain, along with cyclic tensile stress (yanking). The solution to Fireblade’s cam-drive problem was to wrap the cam chain—not around the usual small crank-mounted sprocket, but rather around a larger and less bumpy sprocket driven from the crank by a reduction gear.

With this change, the cam drive stabilized and the simple valvetrain I saw became highly reliable. Ishikawa noted that there had been no development problems with the DLC-coated valvetrain parts.

Each time motorcycle performance advances—as it has in the 2020 Fireblade—problems like this one can appear and must be quickly crushed to keep the program on schedule. Remember that the Fireblade’s peak-power rpm today is 60 percent higher than that of the big sit-up liter-bikes of 40 years ago.

When Honda’s 750cc V-4 RC-45 Superbike was raced during the late 1990s, black streaks sometimes appeared on its con-rod big-end bearing shells. The bearings didn’t fail, but the marks were a warning. Increased oil pressure changed nothing: The marks remained, mocking. So before raising peak revs to 17,000 for the next season, the engineers completely changed the oil system. They stopped bleeding oil from the main bearings to feed the rods in the usual automotive fashion but instead injected it into the end of the crankshaft. Now, with centrifugal force helping oil to reach the rod bearings rather than hindering it, the streaking disappeared and engine lubrication became fully reliable with just 12 psi of oil pressure.

Because the new Fireblade will compete in World Superbike, HRC has given it this same “end-feed” oil system.

“Both ends,” Ishikawa said, when I pointed to the left side of the cutaway engine. “We inject oil into both ends of the crank.”

I asked him which feature of the new engine pleases him most.

“The way the intake system is mounted, which helps it to be very short.”

It is difficult to make intake systems short enough for tuned operation at high revs, and intricate machining was required to achieve this as the RC30 V-4 750cc Superbike of 1988 was made, going on to win two championships with Fred Merkel as rider. Normally the carburetor or throttle body has a spigot that fits into a molded rubber socket on the engine, held in place by a steel clamp band. But because this adds length, a different design was adopted in which the engine side of the throttle body is pressed axially against an elastomer seal by rubber-grommeted fixing bolts. These features were clearly revealed in the cutaway engine.

Finally I asked the question of most interest to myself: “Can you now design a chassis, knowing how much stiffness or flexibility it requires in bending, twisting, or flexing laterally?”

“We can now predict what will be the effect of small changes to this shape,” Ishikawa said, running his hand over the flare of the Fireblade’s right-hand chassis beam as it curved away from the steering head.

MotoGP teams constantly test new chassis. If from all this trial and error a successful predictive model has finally been created, that would be wonderful news. In our video conference, Kuwata had parried this question with generalities. Now I would have to be satisfied with Ishikawa’s definite but limited statement.

TWIN-RING MOTEGI AND THE HONDA COLLECTION HALL

Roughly 60 beeline miles north of Tokyo is Honda’s Twin Ring Motegi race circuit and the Honda Collection Hall. Japan’s backbone is a volcanic island arc whose erosion forms a flat outwash of arable land on which most of the people live. Motegi itself is in a bowl of hills that looks chosen to contain the sounds of racing, thereby parrying the noise-abatement forces that now threaten circuits such as Monza. It is a theme park and a village of shops, restaurants, and hotels. In the distance are snowy peaks.

Admission to the Collection Hall is free, and the first thing you see as you enter is powerfully symbolic. It is Mr. Honda’s command, “Dream,” inscribed in his calligraphy on an 8-foot glass disc, encircled by what can only be described as three giant piston rings. How do I know? All three have a gap, just as piston rings do. When a young Mr. Honda decided that he must design and manufacture—not just repair—his first product was piston rings. When they were rejected, he studied metallurgy, talked with engineering professors, and was able to develop a manufacturing process that worked. That was the model for his future: Intelligent research and development underlie success.

Often repeated is Mr. Honda’s statement that “more is learned from failure than from success.” In racing, when we win, we party. When we lose, we must understand and correct the causes of failure. For Honda, racing has been an essential form of education and motivation, because you can’t finesse physics; to use it, you must understand it.

On the second floor, I would see Honda’s first answers to Japan’s postwar need for affordable transportation, beginning with fast-evolving bicycle clip-on motors. There was intense competition from roughly 200 other startups driven by the same idea. Who would survive? With a destroyed economy, few had any use for heavy, traditional motorcycles. The winning product was the easy-to-ride step-through Super Cub, with big wheels that made easy work of rough-going. Its explosive popularity has led to over 100,000,000 sales since 1958. Driving repeat business was a strong dealer network providing product support.

The production of these bikes did not, as so many at the time claimed, depend on cheap labor, but rather on the most cost-efficient modern manufacturing systems and research tools—Japan was starting over. A 1952 photo shows Mr. Honda, grinning as he’s about to board a Northwest Stratocruiser for a tool-buying trip to the US.

In Honda’s No. 2 Research Section in the late 1950s, engineers Kimio Shinmura and Tadashi Kume proved by testing that it was much easier to achieve high-rpm reliability with four light valves per cylinder rather than the two heavier valves preferred by British and European manufacturers. That high-rev reliability became Honda’s path to world roadracing championships won, from 1962 to 1967. Today, four valves per cylinder are the majority choice for motorcycle, car, and light-truck engines worldwide.

My special interest focused on the long series of classic roadrace bikes, extending from Honda’s first Isle of Man entries in 1959 to the team’s withdrawal after 1967. Racing resumed as Honda assisted French endurance-racing teams in the early 1970s, resulting in the twin-cam production CB750F of 1979 and the CB900F/RS1000, with which American Honda entered US superbike racing in 1980. Meanwhile, in the midto late 1970s, an improvised organization known as NR Block began to research ways to defeat the growing power of two-stroke GP bikes. Their concept was to make pistons oval so that eight valves could provide necessary gas flow at ultra-high revs to pistons narrow enough to achieve fast combustion. The NR was not successful, but knowledge was gained. From 1982, Honda switched to two-stroke roadrace bikes, culminating in Mick Doohan’s remarkable five 500cc titles in a row, from 1994 to 1998. The Collection Hall presents all of these steps for study.

Although much technology is invisible, I could clearly see steps taking place as Honda competed at international level. The first engines had upright cylinders, but to guide cooling air to the hot region between the valve covers (directly over the combustion chambers), the engineers had improvised air scoops. The next designs inclined the cylinders forward, making that area act as its own “air scoop.” Cam drive by shaft-and-bevel gears located at one end of the crankshaft was abandoned because shafts are torsionally springy. In their place came rigid, central-spur gear drive. For years, central cam drive would be a feature of many production four-cylinder designs. Large crankshaft ball bearings were replaced by much lighter and more compact caged needle rollers.

How stiff should a chassis be? Chassis engineer Toshiji Baba and his department found out, and simple backbone frames, then braced backbones, and finally wide twin-loop frames followed, making bikes more stable and faster maneuvering. Beautiful parts catch the eye everywhere, from the flowing shapes of aluminum fork crowns to the masses of deep engine-cooling fins. Carburetion was iffy with European-style remote float bowls, so tiny and complex integral-float carburetors took their place. Driven by competition, development moved fast.

Honda’s Collection Hall is not a static salute to a dead past—Mr. Honda was suspicious of museums because only the future interested him. These machines are a demonstration of the process by which R&D continually advances the state of the art, with HRC at the center of this drive.

FIREBLADE HAS CHANGED

Over many years, the motorcycle press has come to expect a comfortable compromise from Honda sportbikes. Let the others bring narrow racetrack powerbands and cramped riding positions; Hondas scored in Supersport racing without making their riders endlessly stir the gearbox while carrying half their weight on their wrists. Yet there are hints of dismay in some early reviews, that CBR1000RR-R has become less of a “gentleman’s express,” with a harder focus on uncompromised racing qualities. As one example, Fireblade’s engine gives its claimed peak torque of 88 pound-feet, only 2,000 revs below peak power.

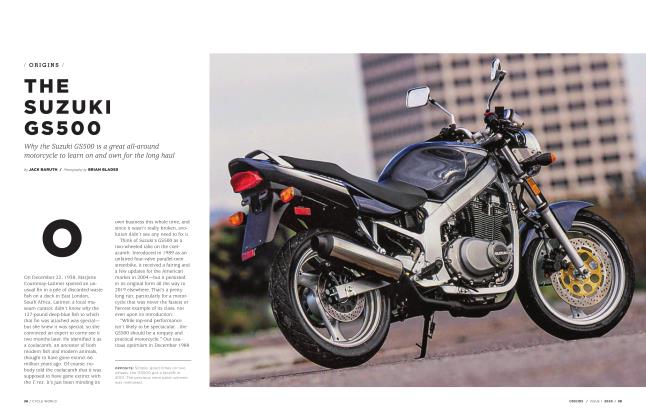

Sorry, folks, that reflects the reality that our world has changed. Back in the heady days of 2005 and before, the reason to produce a high-performance large sportbike was to motivate riders to buy lots of them. And they did! They bought so many that pressure built up to drop World Superbike’s 750cc fours/1,000cc twins formula in favor of the liter-bikes that had meanwhile become top sellers. In the US, AMA Superbike had switched down from 1,025cc to 750 in 1983, and World Superbike had begun at 750 in 1988. Why drop the original big formula? Because the technology of the 1980s made 750s seem better-suited to existing race tracks.

Then came a big change: Liter-bikes of the late 1990s were designed from the beginning to be raceable, without the extensive professional modifications that Superbikes of 1975 to 1982 had needed. When racing formulas returned to 1,000cc, these more-capable big production bikes proved to be quite raceable on existing tracks.

Winning in World Superbike is no casual thing today; it takes serious R&D and a highly specialized motorcycle. To compete in that arena, Honda’s new Fireblade has had to become that motorcycle

Why did Honda build it, if not for the few sales in today’s small sportbike market? “World Superbike is the top category of production racers,” HRC’s Kuwata said. “If we need to show to customers our technology is the best, we need to show them our bike is very fast.

“This is very good also for the business, because now in the market, the customer has a lot of choices.

It’s true that sportbike sales are going down, but the CBR1000RR-R is a flagship motorcycle. Maybe not all want to buy it, but Honda’s image benefits from being at the top of racing categories.”

Racing has created these more-capable motorcycles.

At Honda, HRC (and long before it, No. 2 Research Section!) develops advanced technology for winning, and then in consultation with production and Honda, R&D finds ways to make that technology useful and affordable to all riders in production motorcycles.

View Full Issue

View Full Issue