PUMPS

IGNITION

TDC

THEY'RE WAY MORE COMMON THAN YOU THINK

KEVIN CAMERON

Engines are air pumps, identical in concept to gas-station air compressors but much more efficient because of the years of refinement lavished upon them by airflow specialists armed with flow benches. A brake master cylinder is a pump. Bike engines have oil and, usually, water pumps. Racing engines may have oversize oil scavenge pumps to evacuate their crankcases, saving power that would otherwise be wasted in pumping loss. Superchargers and turbochargers are pumps. The crankcases of two-stroke engines are used as freshcharge pumps. Sound waves moving in intake or exhaust pipes pump air in or exhaust gas out. Lots of pumps. Lots of pumping going on.

Pumps move fluids. Four-stroke engines spend half their time as pumps— pumping fuel-air mixture in and exhaust out. Small detail changes applied to their valves and ports can have large flow effects. By proper use of delayed intake valve closure and application of intake kinetic energy, an optimally designed engine cylinder may take in and trap as much as 125 percent of its own volume.

The brake master cylinder uses a solid column of brake fluid as a pushrod to press the brake pads against the discs.

A hydraulic clutch master cylinder pumps fluid to separate and release the clutch plates.

Liquid coolant is circulated by a small centrifugal pump. The pump side of a turbocharger and the supercharger of Kawasaki’s exclusive new H2 are both also centrifugal pumps. A rotating circular disc carries radial vanes on one or both faces, and fluid (air, water, etc.) between the vanes is accelerated to the tip speed of the wheel. That velocity energy then becomes pressure as the high-speed flow from the edge of the wheel is decelerated in the surrounding scroll housing.

Early motorcycles had hand-operated piston oil pumps that allowed the rider to move oil from a supply tank into the crankcase, where the moving parts splashed it onto bearings and cylinder walls. As the engine ran, this oil was lost past piston rings and valve guides. How did the rider know when more was needed? He looked behind him; if there was no smoke, it was time for a shot or two of oil. Later came recirculating systems using two-gear oil pumps. A pair of equal-size gears in mesh moves oil from one side of their figure-eightshaped housing to the other in their tooth spaces, while back leakage is prevented by the meshing of the teeth in the middle. Two such pumps were needed if the oil was carried in an external tank— a small pump to supply bearings and cylinders with oil and a larger scavenge pump to pick up the used oil and return it to the tank.

The Roots supercharger used on Top Fuel dragsters is conceptually a very large two-gear pump, each of whose “gears” has only two teeth. A variant on this is the Lysholm, or screw compressor, in which the rotors are twisted into helical shape. A Roots blower has no internal compression, as its rotors sweep air around at constant volume. Screw compressors, because they do perform internal compression, use less power in achieving a given delivery.

Recent motorcycle engine oil pumps are often of the “gerotor” type. A cylindrical outer rotor is made with inwardfacing “teeth” (actually, they are more like rounded humps) that mesh with an inner rotor with outward-facing teeth. The inner rotor has one fewer “tooth” than the outer, and the parts are so shaped that “tooth-to-hump” clearance is always very small. The parts are so shaped that the spaces between teeth are increasing in volume in one area and decreasing in another. Ports in the end plate(s) transform this geometry into a pump, internally sealed by close clearances between inner “teeth” and outer humps. It sounds complicated, but one glance reveals its simplicity.

BY THE NUMBERS

5,000 HORSEPOWER OF THE MASSIVE DIESEL WATER PUMP BUILT IN NEW ORLEANS BYTHE ARMY CORPS OF ENGINEERS. IT CAN MOVE 150,000 GALLONS OF WATER PER SECOND!

2 NUMBER OF PUMPS IN THE HUMAN HEARTTHE LEFT VENTRICLE AND THE RIGHT VENTRICLE.

500,000 GALLONS OF DIESEL FUELTHATNEEDEDTO BE PUMPED OUTOFTHE LISTING COSTA CONCORDIA, THE ITALIAN CRUISE LINER THAT RAN AGROUND IN 2012

The once-common crankcasescavenged two-stroke engine uses close-fitting sealed crankcases and undersides of the pistons as air pumps to draw in air from the carburetor then compress it and transfer it from crankcase to cylinder through short ducts called “transfer ports.” Even in fourstrokes, the undersides of pistons pump air—an inconvenient truth. At very high rpm, these accidental air pumps generate serious power loss, so even in production sportbike engines, ports are cut through main bearing webs to ease the flow of air between the adjacent cylinders of inline engines as their pistons move up and down. Part of the poor aroundtown mileage of four-strokes comes from “pumping loss,” which is the power required to pull a partial vacuum in the cylinders at idle and low throttle angles.

Crankshafts that fit too closely in their crankcases have also acted as accidental pumps, sometimes picking up oil before it can fall into the sump or be returned by scavenge pump to an external tank. Such oil, trapped in the narrow clearance between whirling crankshaft and crankcase, consumes a lot of power, and so its temperature rises steeply, reducing its lubricating ability. The paddock term for this condition is “wet sumping.” Again and again in the development of racing singles, engineers have reduced crank wheel diameter to prevent this kind of power loss. Scrapers and perforated metal screens have also been used to slow fast-moving oil so it can bypass all this action and serenely drain back to sump or scavenge pump. This problem and these techniques have existed for more than too years.

In V-twins (especially those with a narrow V-angle) and singles, there is a large rise and fall in crankcase pressure as pistons fall and rise. This pressure variation has often interfered with the movement of oil, returning from the head(s) to the sump through pushrod tubes or cam-drive tunnels, leading to oil pooling “upstairs.” In severe cases, small oil pumps have been placed in the head to deal with this, or the amplitude of the pressure variation has been reduced by increasing case volume (by connecting the crankcase to either an under-engine sump or to the primary chaincase). Dealing with this problem is part of the development of every V-twin, so its literature is considerable.

BY PROPER USE OF DELAYED INTAKE VALVE CLOSURE AND APPLICATION OF INTAKE KINETIC ENERGY AN OPTIMALLY DESIGNED ENGINE CYLINDER MAY TAKE IN AND TRAPAS MUCHAS 125 PERCENT OF ITS OWN VOLUME.

Let’s not forget (I nearly did) the suspension dampers, which dissipate unwanted chassis motion by pumping oil through restrictions.

When all these pumps behave as intended, pleasant motoring becomes possible.

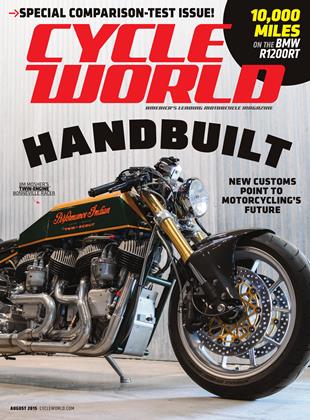

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontOn A Wing

August 2015 By Mark Hoyer -

Intake

IntakeIntake

August 2015 -

Ignition

IgnitionRacer Ride

August 2015 By Blake Conner -

Ignition

IgnitionSomething For Nothing?

August 2015 By Kevin Cameron -

Cw 25 Years Ago August 1990

August 2015 By Don Canet -

Ignition

IgnitionTop Priority: Street Riding Use Your Imagination

August 2015 By Nick Ienatsch