Service

STRANGE TIRE WEAR DRY OR WET SUMP? BEST USED BIKE FEEDBACK LOOP

Reader Jean-Claude Dehmel might not hang it out like Ryan Dudek (few do), but the strange front tire wear he experiences on his Diavel suggests he's no stranger L to hard cornering.

THE DEVIL MADE HIM DO IT

Q: I have a 2013 Ducati Diavel, and I am puzzled over the odd wear on the OEM front tire, which I replaced at about 9,000 miles. The right half of the tire was worn enough to have a near-flat surface, but the left side had normal wear. The rear tire was fine but also replaced because of mileage. After the tire change, the Ducati dealer inspected the fork, road-tested the bike, and found nothing wrong with the alignment or handling. They speculated various causes ranging from front tire underinflation (but I regularly check tire pressures), turning harder on right turns than on lefts, and simply a defective tire.

One thing I noted (and fixed) was the compression damping setting on the right fork, which was different than on the left—four turns out as compared to one and a half on the left. The dealer said this should not cause the tire to wear unevenly because the fork works as one unit. Time will tell how the new front tire performs, but I still would like to know your professional opinion of this uneven wear.

JEAN-CLAUDE DEHMEL FAIRFAX, VA

A Once all the fasteners on the front end are torqued, from the B triple clamps to the axle pinch bolts and the axle itself, the fork is a boxed structure. The inner fork tubes then move up and down in unison, keeping the front wheel perfectly parallel between them, regardless of any difference in damping settings between legs. In fact, most highperformance racing forks and quite a few production-bike front ends even have the compression-damping control in one fork tube and the rebound in the other. So the differences in your fork’s compression settings clearly did not create the problem.

Actually, it is not unusual for a front tire to wear more quickly on one side than the other. In any country where bikes and cars ride and drive on the right side of the road, for example, every right turn is sharper than the left turn on that same corner. This

means that in any given corner, you’re almost always going slower when turning right than left while also likely doing more trail-braking; and on some motorcycles, depending upon their steering geometry, wheelbase, weight distribution, and tire choice, riding aggressively through slower turns can cause the front tire to “scrub” more than when rounding faster corners, accelerating the wear on that side.

Road design can also have an effect.

In areas where most of the roads are crowned in the center for better water drainage, bike tires tend to wear faster on the left than right, particularly if the rider is not inclined to charge the corners.

Obviously, you ride your Diavel pretty aggressively through the turns. Given the bike’s long wheelbase, relaxed frontend geometry, and awesome power, getting 9,000 miles out of its highperformance front tire is exceptional, despite the accelerated right-side wear.

SUMP-THING TO PONDER

Over the years, I’ve owned many different motorcycles of varied * styles and makes, each very cool in its own way. One of the mechanical concepts I’ve never before thought about is the engine’s sump, wet or dry. WR426? Dry, with the oil in the frame. V-Strom? Wet. F-l motors? Dry. FX motors? Wet. Question is, why? What makes a wet sump or a dry sump better for one motor and not the other?

JOEGAUN FLAGSTAFF, Al

Fots of reasons. A wet sump increases overall engine height, as it must be large enough to contain the necessary volume of oil and spacious enough to prevent the crankshaft throws from plowing through the oil, creating friction that can rob power. If the designers want their new engine to be as short as they can make it, either to keep the bike’s center of gravity as low as possible or allow the motor to fit into the intended frame—or both—they might opt for a dry sump. The crankcase can then be virtually shrink-wrapped around the crankshaft while still permitting a large external oil volume and preventing the friction loss of a crank splashing through oil.

GOT A MECHANICAL OR TECHNICAL PROBLEM with your beloved ride? Perhaps we can help. Contact us at cwservice@cycleworld.com with your questions. We cannot guarantee a reply to every inquiry.

A dry sump also simplifies the all-important task of maintaining a constant oil supply to the engine’s critical components under severe acceleration and braking, as well as during high G-force cornering.

It’s much easier to control the pickup and delivery of oil in a very confined space than it is to manage a large volume sloshing around in a big container. Plus, even without any type of oil cooler, dry-sump systems generally reduce oil temps better than wet-sump styles simply because the oil is routed out of the hot engine and into an external container before being returned to the source of the heat.

Dry-sump systems usually are more expensive, though, requiring two oil pumps—one to feed, one to scavenge—along with external lines and an adequate oil reservoir, which either has to be built into the frame or maintained in a separate tank. Both systems can be made to work for most applications, but the designers have to decide which they believe is the best and/or most financially sensible for any given machine.

FEEDBACK LOOP

Regarding the sputtering Suzuki GSX-R600 discussed * in a previous Service (March 2014): Suzuki has issued a service bulletin about loss of rpm during steady cruise, exactly like Mr.

Tillman of St. Louis describes. The O2 sensor is the culprit. Thought you might like to know. Love the magazine. I subscribe to several of the now-Bonnier pubs. CWis my fave.

EDESKEW PEACHTREE CITY, CA

A: ! Thank That’s excellent you for sharing information. it with our readers.

LEAN GREENIE

I just finished an engine rebuild on a 2005 Kawasaki * KX250F. While cleaning the carb and installing the jets recommended by Pro Circuit, I found the hot-start plunger was stuck in its bore. A local shop that I trust had to use heat, an Easy Out, and a drill to remove it. The engine now is hard to start and it won’t idle once the choke is off, but it pulls well from about 2,000 rpm on up through the rev range. It’s clear to me that the engine is lean just off of idle because it makes the popping sound I associate with a lean condition. I took the carb back to the shop to have it cleaned (it looks new now), but that made no difference. I stuffed plastic wrap into the hot-start orifice to eliminate problems with that circuit, but that didn’t help, either. I have been working on engines all my life and have never been so stumped. Any suggestions?

JOHN WOOLSEY YUCAIPA, CA

AB hot-start The culprit circuit. here is Unlike still the the H cold-start mechanism, which richens the mixture, the hot-start circuit does the opposite, leaning the mixture to make firing the engine easier when it is fully warmed.

Like many single-cylinder, highperformance dirt bikes, the KX250F runs rather hot in normal operation. When the hot engine is shut off, that heat soaks into the carb and causes the fuel in the float bowl to begin vaporizing. That results in a too-rich mixture if you try to start the engine before it cools. Pulling the hot-start lever on the handlebar operates a cable that slides the plunger aside, opening a separate air circuit in the carb that leans the mixture enough to allow easy starting.

Here’s the problem: When you stuffed plastic wrap into the hotstart bore, that prevented outside air from entering the carb, but it did not shut off the circuit. The hot-start leanness is created through circuitry inside the carb, not via air drawn in through the plunger bore. You need to install a new plunger, assuring that nothing in its bore prevents it from fully sealing the circuit closed when the hot-start system is off. If the bore was damaged during the shop’s extraction of the original plunger, you probably will need to replace the carb body.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontArtisanal Toast

June 2014 By Mark Hoyer -

Intake

IntakeIntake

June 2014 -

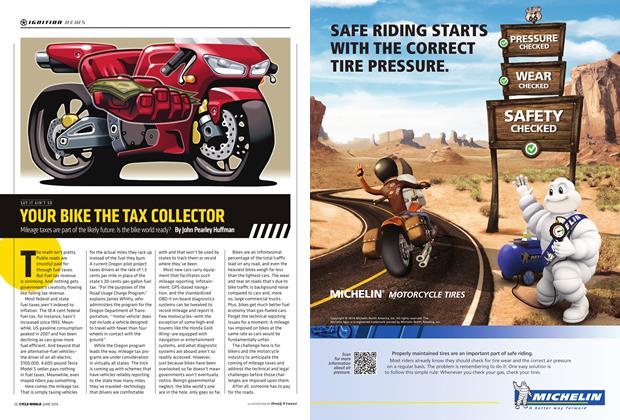

Ignition

IgnitionSay It Ain't So Your Bike the Tax Collector

June 2014 By John Pearley Huffman -

Ignition

IgnitionCw 25 Years Ago June 1989

June 2014 By Andrew Bornhop -

Ignition

IgnitionSave Your Senses It All Adds Up

June 2014 By John L. Stein -

Ignition

IgnitionWhere Did the Weight Go?

June 2014 By Kevin Cameron