HOW WE DO THINGS

IGNITION

TDC

ROCKETS, TWO-STROKES, MIXTURES AND COATINGS

KEVIN CAMERON

Technology gets mixed reviews from the intellectual crowd. Critics point to the atom bomb and Love Canal, but at the same time, cities would be uninhabitable within a week were it not for railroads and diesel trucks. With all its faults, technology just means how we do things. Farming with a sharp digging stick or waiting motionless for hours, lance in hand, at a seal’s breathing hole on the sea ice are technologies just as much as is desalinating water using graphene molecular-scale filters.

That being so, I confess to being permanently fascinated by technology. When I recently arrived at John Wayne Airport (SNA),

I couldn’t help noticing that the instant the wheels touched the runway, the pilot had the spoilers up, the engine thrust reversers roaring and the wheel brakes on hard. So I paid close attention when we turned off.

This was a classic short-field landing; we’d used the whole runway! Later, I learned that SNA is about the shortest runway in the U.S. regularly used by commercial jets—5701 feet. The sociology? Just what you’d expect: Airports were originally built on vacant land nobody wanted and then cities spread, fillingin around them. Naturally, nearby residents complain about aircraft noise.

I loved to hear 750 Superbikes warming up because of the richness of their soundall the tiny clicks from tappet clearance being taken up by cam lobes merged into a whoosh in just the same way the individual clatterings of leaves excited by wind join to become that wind-in-the-trees sound.

And the exhaust: Individual pulses become tones, deeper ones reinforced by pipe length. The current Yamaha Ri, with its 90-degree “Furusawa crank,” has an irregular firing order that generates more than one tone, giving a resonant, almost V-Eight sound.

Drive chains and cam chains make their own contribution. A roller chain cannot wrap smoothly onto its sprockets like a flat belt on pulleys does because the chain bends only at its joints, forming a polygon. The rise and fall of that polygon’s apexes (apices?) as a sprocket turns generates a slight impact as each roller drops into its tooth space. Result: the “Zhhh” sound that seems so loud if the engine for any reason becomes suddenly quiet at speed.

The U.S. briefly deployed an anti-ballistic missile system that included the “Sprint” short-range missile, which looked like the wizard’s tall conical hat, magnified. If you Google “Sprint missile launch video” you will see this crazy thing—which took off at loop—streak up out of its silo, turn about 70 degrees and disappear at impossible speed. It did the quarter-mile in 0.92 second. Sprint was hot stuff once, but now it’s just mysterious abandoned concrete installations somewhere.

I like to see film of the Space Shuttle main engines coming to life via their auto-start sequence. Since they burned liquid hydrogen/liquid oxygen, their exhaust “flame” was pure superheated steam—completely transparent except for a tiny blue cone, floating in its midst. Starting is a rough time for liquid rocket engines because if the mixture reaching the propellant pump turbines is not comfortably rich, those turbines will instantly burn to white-glowing vapor in the heat and/ or excess oxygen. Sorta reminds me of two-stroke pistons in the late 1960s’ aircooled days. Air-cooled engines didn’t cool well enough to keep their pistons healthy on a peak-power mixture, so we enriched them a couple of sizes—the very same fuelcooling scheme that kept the Space Shuttle’s 8o,ooo-horsepower turbopumps alive during those grueling eight-minute burns. Once you get it right, it’s all in a day’s work.

And, if you watch film from the great Apollo launches, you may see more of the same at brennschluss (what Wernher von Braun and that program’s other German engineers called engine shutdown). To stay on the safe side as that “five-some” of million-and-a-half-pound-thrust engines smoothly powers down just before fuel

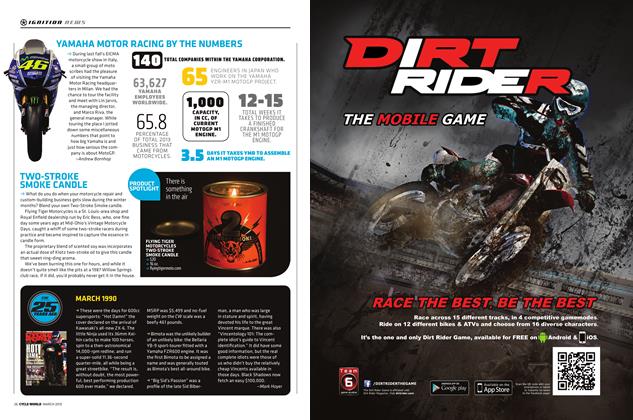

BY THE NUMBERS

TOTAL WEIGHT,

IN POUNDS, OF THE AIRCRAFT ENGINES IN MY SHOP

NUMBER OF CNC MACHINES IN MY SHOP

THE U-BOAT FROM WHICH MY GERMAN GAP-BED LATHE WAS SALVAGED

(U-873 WAS SCRAPPED IN 1948.)

exhaustion, propellant valves move to enrich the mixture, making the normal red kerosene flame an even darker red. It was just common sense—same as two-stroke enrichment. As Kawasaki’s race technician Kazuhito Yoshida advised us in 1973, “Safety-side.”

If a bike had transparent headers, we’d see the exhaust flames redden (richer mixture) during on-ramp acceleration, then fade to a pale whitish glow (chemically correct) at steady speed.

Today no one ever sees a racebike’s sparkplugs—that’s why there are oxygen sensors tapped into the headers or the collector pipe. No more sparkplug-reading wizardry from the likes of the late and respected Bobby Strahlman, Champion Spark Plug’s man-at-trackside. Fuel mixture is a software matter now. To make 240hp MotoGP bikes finish 45-minute races on 21 liters (5.5 gallons) of fuel, the software aces consult with engine-development people to come up with schemes that save fuel with minimum disturbance to function.

Remember when titanium valves were just coming into use? Teams used Ti intakes and exhausts for sprint races but used more rugged stainless exhaust valves for longer races. Ducati had a bimetallic valve for a time—part titanium for its 40 percent weight savings but with a hard steel stem. Over time, improvements arrived that would allow titanium valves to be confidently used even in streetbikes. This replays the valve problems of supercharged aircraft engines in the 1930s. Valves had been made of high-speed steel— cutting-tool material that kept its hardness even at red heat. But not so fast: When Thomas Midgley discovered the powerful anti-knock effect of tetraethyl lead, those tungsten steel valves “looked like they’d been dipped in molten slag” after just a few hour of operation on leaded fuel. Then came austenitic stainless, which survived leaded fuel just fine and is closely related to the 18/8 stainless used in kitchenware. When growing engine power resulted in breakages of temperature-weakened valves, they were internally cooled by partially filling hollow interiors with sodium. The filling, liquid at operating temperature, carried heat away from critical regions, up the valve stem and into the guide. Norton, in its 1953 factory engines, even cooled the valve guides by surrounding them with a spiral oil passage.

When hot gases eroded the seats and valve-sealing surfaces in those 1930s’ aircraft engines (five continuous minutes on take-off power), they made the seats out of early superalloys and coated the valves with similar stuff. We find the same techniques in use todaycoatings that resist hot-gas attack better than naked stainless or titanium. Coatings work on people, too—wool in winter, sunscreen in summer.

IF A BIKE HAD TRANSPARENT HEADERS, WE'D SEE THE EXHAUST FLAMES REDDEN DURING ACCELERATION, THEN FADE TO A PALE WHITISH CLOW AT STEADY SPEED.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Ten Rest

September 2013 By Mark Hoyer -

Intake

IntakeIntake

September 2013 -

Going Mobile

September 2013 -

Ignition

IgnitionSound And Fury Carb Your Enthusiasm

September 2013 By John Burns -

Ignition

IgnitionCw 25 Years Ago September, 1988

September 2013 By Blake Conner -

Ignition

IgnitionOn the Record Troy Bayliss

September 2013 By Don Canet