SERVICE

PAUL DEAN

Hell hath no fury...

QMy 2006 Harley Heritage Softail Classic has developed a strange noise. It's a brief chirping sound that I often hear when I decelerate or sometimes when I downshift. What's weird is that I hear it more often with my wife on the back. Do you have any idea what might be causing this noise or will I have to stop taking my wife along when I go for a ride? David Weaver

Garland, Texas

AIf you think your Softail chirps, just wait until you tell your wife she can no longer ride with you. I have no advice for that problem.

But although I'm no marriage counselor, I do know of several mechanical conditions that can cause chirping and squeaking noises on Harleys; and in the case of your Softail, I think you need to either adjust or replace the final-drive belt. If the belt gets a little too loose, its top run can momentarily hit the upper inside edge of the primary case, making the chirping noise you are hearing.

It only does this on deceleration because that is when the belt's top run is its slackest. During acceleration, the engine is driving the rear wheel via the transmission pulley, so the top run of the belt is pulled tight; but during deceleration, the rear wheel is driving the engine, which makes the belt's bottom run taut and its top run slack. If the belt is too loose, that excess slack can allow it to flutter up-and-down during deceleration just enough to cause the back side of the belt to briefly make contact with the primary case, producing the chirp. This occurs more often when your wife is aboard because her added weight (and I'm certain you merely forgot to mention that she's a trim, petite young beauty) compresses the rear suspension more than usual, which moves the top run of the belt even closer to the upper edge of the primary case.

When correctly adjusted, the belt should have between 5/i6and 3/8-inch of deflection measured at the middle of the top run with 10 pounds of force applied at that same point. I've seen and heard about numerous methods of providing that force, but most involve either pulling on the belt with a fishweighing scale or simply placing something that weighs approximately 10 pounds on the belt at the specified area. Once you get the belt properly adjusted, all of your chirping issues— whether mechanical or marital—should be resolved.

Unsticking your gears

QIn an interview with a female rider, Krista Cardinale, that appeared in the Moto Intro section of your August issue, she made a reference to "how to roll out the clutch if your gears get stuck while at a light." Great question that I would like to know the answer to, as this has happened to me on the road. Robert Greene, Jr.

Macungie, Pennsylvania

A Motorcycle transmissions are not at all like their automotive counterparts: They don't like to be shifted when the bike is at a standstill. The worst thing you can do when this happens is to keep mashing on the shift lever; that just bends and gouges shift forks and puts an undue strain on the shift mechanism.

A car transmission uses a series of synchronizer rings to engage each gear, and that system allows the driver to shift gears no matter if the car is moving or not. A motorcycle tranny, however, employs what is called dog-type engagement. The affected gears have lugs (called dogs) of one shape or another that protrude from their sides; and as the rider shifts, those gears are slid sideways to engage with dogs or slots in adjacent gears. But if the dogs on one gear are not almost perfectly aligned with the dogs/slots on the other and the bike is not moving, the transmission won't shift; instead, the outer ends of the dogs just bang into one another or into the areas between the slots rather than engaging.

This is where moving the bike comes in. No matter what gear you might be trying to select, one of the engaging gears is connected to the engine via the clutch and input shaft, while the other gear is connected to the rear wheel via the output shaft and final drive. When the bike is motionless and the clutch is disengaged, neither gear is moving, even if the engine is running. So, if the dogs or slots of the two gears you are trying to engage are not aligned, the transmission won't shift. But you can change the orientation of the gear on the output shaft by simply rolling the bike either forward or backward a few inches, and you can change the postion of the gear on the input shaft by engaging the clutch ever so slightly—not enough to cause the bike to lurch forward but just enough to make the gear rotate a degree or two. If you do either of these things while pushing gently on the shift lever, the gearchange will be successful. Once you get the hang of it, you even can perform both techniques at once, rolling the bike forward or backward very slightly while also moving the clutch lever just to the very point of initial engagement.

Cornering XL-ence

QI live to corner hard on my 2008 H-D Sportster, but the bike wobbles when 1 do my cornering exercises. It's not an uncontrollable wobble but is enough that I have to back off instead of accelerating. This is my second Sportster, and the first one never had this problem unless I pushed the envelope.

Sportsters probably aren't the most nimble of bikes when it comes to hard cornering, but mine should be doing better than what I'm experiencing. I think it's in the tires, but I'm just guessing. I would be interested to hear what you think is the problem.

Dick (last name withheld by request) Dover, Delaware

A Although you did not mention which tires your Sportster is currently wearing, the problem is more complicated than just putting different rubber on the road—a fact evidenced by the superb cornering performance of the 2008-2012 XR1200/XR1200X. That bike is built on essentially the same frame as your Sportster but is equipped with high-quality, fully adjustable Showa suspension at both ends (a Big Piston inverted fork like those on many current repli-racers, along with piggyback-reservoir shocks), an aluminum swingarm that is much more rigid, and either Dunlop Qualifier or Michelin Scorcher sport tires.

Between 1996 and 2003, H-D built the XL1200S Sportster Sport, which, until the XR1200 came along, was the best-handling Harley ever. But the Sport had a solid-mounted engine, whereas the V-Twins in the Sportsters of 2004 and later are rubber-mounted. This change in engine mounting required a frame redesign that added about 50 pounds of overall weight and made the chassis more flexible, since the engine no longer acts as a stressed frame member. Those factors are not insurmountable in getting the bike to be a better corner-carver, but overcoming them requires more than just a change of tires. In fact, were you to spoon super-sticky tires onto your Sportster and make no other modifications, the wobbling might very well get worse.

What's more, I have no way of knowing just how hard you ride through corners, despite your statement about having "pushed the envelope" on your previous Sportster. What some riders consider blindingly fast cornering is barely above cruising speeds compared to the way many others attack the turns. That makes it difficult for me to suggest specific modifications that will help your Sportster handle to your liking.

Instead, all I can do is recommend that you contact either Race Tech {www. racetech.com) or Progressive Suspension (www.progressivesuspension. com), both of which sell suspension upgrades that can improve your bike's cornering prowess. Progressive has a small line of Sportster replacement shocks that are far better than stock, and Race Tech offers several grades of shocks for XLs, along with its famous Gold Valve Cartridge Emulator Kits for forks. Both companies also have suspension-tuning experts available to advise customers about the best components for their specific needs. And for tires, give the Dunlop Qualifiers a try once the suspension has been modified. None of this will transform your Sportster into an XR1200 beater, but it should handle much better than it does right now.

Getting engaged

QThe clutch in my 2004 Honda VFR800 Interceptor has started

chattering when I pull out from a dead stop. The clutch never slips, even when I power shift or pop the bike up in a wheelie, and it never drags, either. I hate to spring for a new clutch, because aside from the chatter, it works just fine. Is there any (cheap) way I could stop the chatter? Roger Kennedy

Albany, New York

AI could suggest that you knock off the wheelies and power shifts, but I don't want to ruin your fun—and you probably wouldn't stop it anyway. But if you're up to the task of tearing into your bike's clutch, you should be able to identify the source of the problem and remedy it on your own—though I suggest that you buy or borrow an '04 VFR shop manual beforehand.

In many cases, chatter is the result of the fiber clutch plates becoming glazed, which alters their coefficient of friction in a way that makes them "grabby." Instead of beginning their engagement smoothly and gradually, the glazed fiber plates start gripping the steel plates more aggressively than usual. But at this early stage of engagement, there is insufficient spring pressure to maintain that level of grip, so the plates suddenly release and then quickly regrip, repeating this rapid grip-slip-grip-slip cycle until the clutch is fully engaged.

If the plates still have most of their fiber lining remaining, you often can cure the chatter by sanding them with fairly coarse sandpaper—80 grit or similar— until the glaze is removed and a fresh

surface is exposed. It's not a bad idea to give the steel plates a quick sanding, too, while also checking them for warpage or other visible damage. Just remember to reinstall all the plates in the very same order in which they were removed. If you end up replacing all the plates, follow the sequence described in the shop manual when installing them.

Given your apparent fondness for wheelies and power shifting, however, the

chatter may be caused by other factors you should be able to spot while removing the plates. Hard, full-throttle shifts and abrupt clutch engagement can, over time, cause

the narrow tabs on the inside diameter of the steel plates to notch the grooves on the inner clutch hub. Likewise, the wide tabs on the outer edges of the fiber plates can become slightly distorted while beating notches into the slots on the outer clutch hub. Either or both of these conditions can cause not just chatter but also clutch drag and erratic engagement. The only remedy is to replace the damaged components. O

Got a mechanical or technical problem with your beloved ride? Can't seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mall a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax It to Paul Dean at 949/631 -0651; 3) e-mail it to CW1Dean@aol.com; or 4) log onto www.cycleworld.com, click on the "Contact Us" button, select CW Service" and enter your question. Don't write a 10page essay, but If you're looking for help in solving a problem, do Include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Columns

ColumnsUp Front

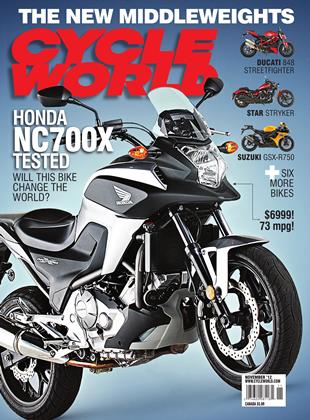

NOVEMBER 2012 By Mark Hoyer -

Roundup

RoundupNo Quarter Given

NOVEMBER 2012 By Blake Conner -

Roundup

Roundup25 Years Ago November 1987

NOVEMBER 2012 By Blake Conner -

Roundup

RoundupWill the Motorcycle of the Future Come From Pasadena?

NOVEMBER 2012 By Kevin Cameron -

Roundup

Roundup2013 Harley-Davidsons

NOVEMBER 2012 By Paul Dean -

Roundup

RoundupOn the Record:

NOVEMBER 2012 By Matthew Miles